File - Srikaran Mahavadi

advertisement

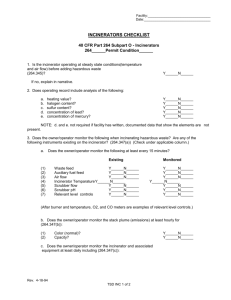

Texas A&M University Biological Waste Facility 211 Sippel Road, College Station, TX 77840 Site Visit Led by Monica Hartmann, CHMM and Josh Freeman, Site Worker Primary Operations The biological waste facility is responsible for the digestion and incineration of animal waste from the departments of Veterinary Medicine as well as other labs on campus that involve dead and diseased animals. Types of biological waste may include horses, pigs, cows, cats, dogs, etc and are accompanied with a variety of diseases such as mad cow disease, rabies, or encephalitis. When a deceased animal has a disease, it is classified as “biohazardous waste” due to the physical/biological nature of it (2). The facility has biological waste delivered to it after being securely packaged, separated, and tagged for proper disposal method (2). Recordkeeping is also strictly managed in order to avoid any accidents or misplacement of biological waste that could escape the facility. An incinerator, a digester, and agrylizer are utilized to treat the waste and the processed waste is taken to landfills after fully dried and accumulated (1). Processes with Potential Pollution The majority of sources of pollution within this facility are associated with wastewater and air pollution. The digester uses 19% NaOH solution and water to digest animal tissue and the wastewater accrued after this process is then deposited to the wastewater treatment plant (1) . The NaOh is siphoned through the silo present in Figure 1. The digested matter was generally a pH of 12-13 and was considered unacceptable based on standards set by the TCEQ for the wastewater treatment plant. Due to a maximum of pH 10 for the plant, very large volumes of water were used to dilute the pH and this quickly became unsustainable due to the demand (1). After much testing, the NaOH was determined to be most effective at 19%. Once the NaOH is poured into the digester, the animal waste is cooked for 300 degrees at 8 hours (1). The lid of the digester is not to be opened in order to avoid the risk of dead matter becoming airborne. After digestion is fully complete, the bones are completely brittle and completely dried before taken to a landfill (1). Figure 2 showcases the digester used at the facility and small parts of tissue and fat are present in the bucket. Figure 1-NaOH Silo-Used for digestion within the digester Figure 2-Biological Waste Digester The incinerator has apparent pollution hazards through the smoke being emitted as a byproduct of burning animal tissue and fat (1). Due to the original incineration unit being too large for the facility, the unit was redesigned to be smaller and fitted with a ram to push the animal matter into the incinerator (1). The TCEQ has placed a limit of no more than 2.68 million pounds of biological waste per year. There is also a maximum on burn hours of 876 hours per year and it must also not burn before or after sunset (1). TCEQ also sets limitations on the medical waste that can be processed through the incinerator. No more than 10% of medical waste such as syringes, gauze, bedding etc. are allowed to burn to minimize any non-biological waste emissions (1). Figure 3 shows the incinerator with the ram that is used to push the animal waste into the first level of the incinerator and the secondary burner is hidden beneath. Figure 3-Incinerator with ram The dead animal matter is kept in a large cooler which is split into two different sections, infectious and non-infectious (3). This minimizes the risk of any infectious disease being unknowingly spread to the employees working within the facility and informing them of how the waste should be processed (3). The cooler is kept at a temperature of below freezing so that the decomposition of the animal matter is not accelerated and the diseases do not become airborne (3). Chemicals Used at the Facility The major chemical used at the facility is NaOH within the digester. There are no other chemicals present within large quantities that are used in the processes of this facility. Pollution Control and Waste Minimization Limitations set by the TCEQ in terms of quantity and burn hours assist in minimizing excess pollution. The TCEQ also requires that the incinerator be equipped with a Continuous Emissions Monitoring System (CEMS) (1). This allows for carbon monoxide and oxygen to be monitored hourly and averages to be obtained. The smokestacks of the incinerator are also highly managed in terms of particulate matter and opacity of the smoke. Every year, a Relative Accuracy Test Audit is carried out to evaluate the emissions and if they are being monitored properly (1). If this test is not done, Environmental Health and Safety must lock out and tag the machine and cannot be knowingly run without the RATA certification (1). Much of the medical matter is also separated out of the biological waste before any digestion or incineration. The waste is separated into different containers such as liquids, metal sharps, non-hazardous solids, Pasteur pipets and broken glassware, and solid biohazardous waste. All of these containers are appropriately labeled and packaged according to their contents and each container has specific standards (2). The container which holds liquids must be leak proof and durable against thermal or chemical treatment. The metal sharps container must be resistant to punctures by use of heavy-walled plastic and to an applied pressure of 40 psi without any breakage (2). The non-hazardous solids must be contained in heavy-duty plastic bags without a Biohazard symbol or that are colored red or orange which indicate hazardous material (2). The Pasteur pipets and broken glassware are also packaged similarly to metal sharps in puncture-resistant containers (2). The solid biohazardous waste is held in heavy-duty plastic bags clearly labeled “Biohazard bags” (2). Permits/Required Monitoring Title V Air Permit-TCEQ -Limits criteria pollutants being released into the atmosphere -Requires strict monitoring and recordkeeping -Tests on opacity and particulate matter are carried out periodically Special Conditions Permit-TCEQ -Cannot exceed 876 burn hours during daylight (Not before sunset or after sunset) -Cannot exceed more than 2.68 million pounds of biological waste per year -Requires Continuous Emissions Monitoring System -No more than 10% medical waste/infectious waste -Secondary chamber temperatures are to be kept at 1800 degrees Fahrenheit Recordkeeping is strictly kept on at this facility. These records are kept for a minimum of two years: -Periods of operation -CEMS monitoring data -Quality assurance data -Records of carcasses and method of handling -Secondary chamber temperatures -Record of disposal of ash -Operator training -Scale calibration certification -Dates, times and reasons for shutdowns References (1) Personal Communication and Notes-Monica Hartmann, CHMM-Texas A&M Environmental Health and Safety (2) Management and Disposal of Biological Waste at Texas A&M University (3) Personal Communication for Josh Freeman