expt.-4

advertisement

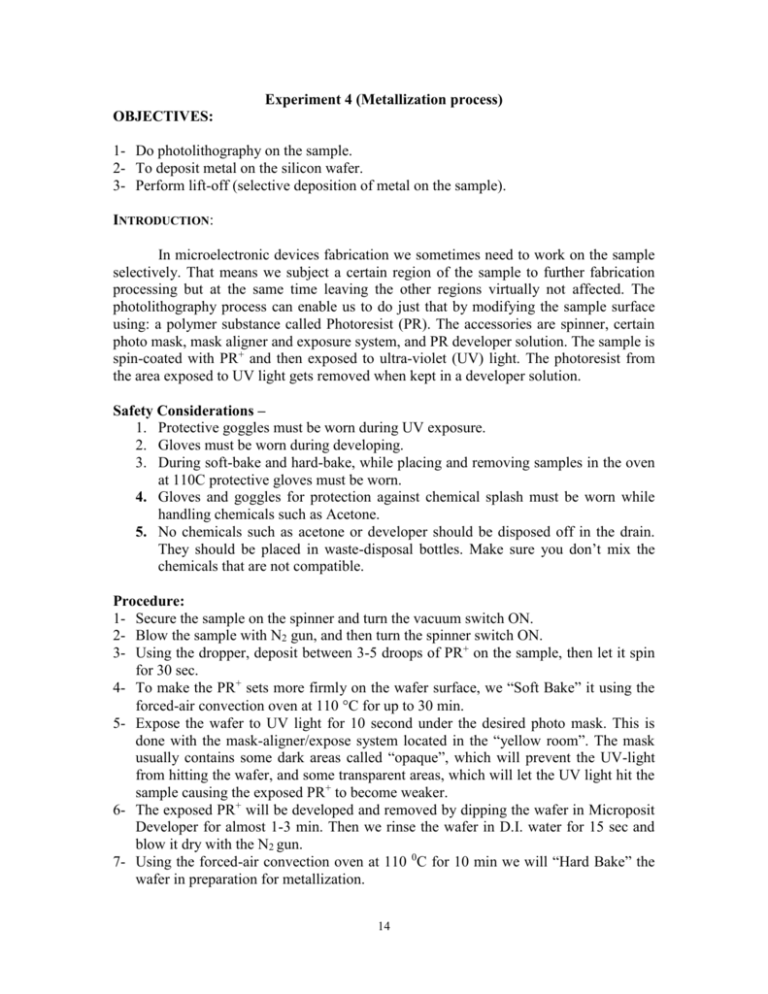

Experiment 4 (Metallization process) OBJECTIVES: 1- Do photolithography on the sample. 2- To deposit metal on the silicon wafer. 3- Perform lift-off (selective deposition of metal on the sample). INTRODUCTION: In microelectronic devices fabrication we sometimes need to work on the sample selectively. That means we subject a certain region of the sample to further fabrication processing but at the same time leaving the other regions virtually not affected. The photolithography process can enable us to do just that by modifying the sample surface using: a polymer substance called Photoresist (PR). The accessories are spinner, certain photo mask, mask aligner and exposure system, and PR developer solution. The sample is spin-coated with PR+ and then exposed to ultra-violet (UV) light. The photoresist from the area exposed to UV light gets removed when kept in a developer solution. Safety Considerations – 1. Protective goggles must be worn during UV exposure. 2. Gloves must be worn during developing. 3. During soft-bake and hard-bake, while placing and removing samples in the oven at 110C protective gloves must be worn. 4. Gloves and goggles for protection against chemical splash must be worn while handling chemicals such as Acetone. 5. No chemicals such as acetone or developer should be disposed off in the drain. They should be placed in waste-disposal bottles. Make sure you don’t mix the chemicals that are not compatible. Procedure: 1- Secure the sample on the spinner and turn the vacuum switch ON. 2- Blow the sample with N2 gun, and then turn the spinner switch ON. 3- Using the dropper, deposit between 3-5 droops of PR+ on the sample, then let it spin for 30 sec. 4- To make the PR+ sets more firmly on the wafer surface, we “Soft Bake” it using the forced-air convection oven at 110 C for up to 30 min. 5- Expose the wafer to UV light for 10 second under the desired photo mask. This is done with the mask-aligner/expose system located in the “yellow room”. The mask usually contains some dark areas called “opaque”, which will prevent the UV-light from hitting the wafer, and some transparent areas, which will let the UV light hit the sample causing the exposed PR+ to become weaker. 6- The exposed PR+ will be developed and removed by dipping the wafer in Microposit Developer for almost 1-3 min. Then we rinse the wafer in D.I. water for 15 sec and blow it dry with the N2 gun. 7- Using the forced-air convection oven at 110 0C for 10 min we will “Hard Bake” the wafer in preparation for metallization. 14 METAL DEPOSITION There are mainly two ways in which metal is deposited on Si: sputtering or evaporation. In the former case ions are involved. In both the cases a good vacuum is needed to allow the metal atoms to deposit. We will use evaporation process. The Metallization is a microelectronic process, by which metal contact to the active parts of the wafer is established. The main equipment needed is a metal evaporator. Here we use AUTO 306. It consists of 3 parts. Vacuum pump Vacuum chamber Heating element We create good vacuum in a chamber where the sample is placed upside down. Then we pass large amount of current through a Tungsten boat where Al metal is kept. This current heat the metal and let Al melt. With more heat, Al evaporates. Vacuum plays a key role in taking Al atoms to the surface of the sample which located about one foot above the Al source. If enough vacuum is not there, Al atoms would collide with air molecules and would be prevented from reaching the surface of Si. The reason we have chosen Al for metallization is that it has low boiling point and therefore easy to evaporate. The current technology of making Ohmic contact doesn’t use Al but polysilicon. This material offers significant advantage over Al which was used about 30 years ago in commercial production. The Metallization process can be carried on in the following manner: 1- Clean the samples by rinsing them thoroughly with DI water then dry them with N2 gun. 2- Load the samples in the evaporation chamber as soon as possible. When the chamber has been properly evacuated (i.e. vacuum down to roughly 10-6 Torr), evaporate the aluminum onto the loaded samples. When the evaporation is completed, the samples may be kept in the vacuum chamber until further processing can be carried out. 3- Take out the samples from the evaporator, and prepare a beaker filled with Acetone. Lift-off Process When metal deposition is done, it is deposited everywhere. We don’t have means to do selective deposition. Therefore we resort to a process known as “lift-off”. By lift-off we mean that metal would be removed from the places where it is not wanted but it would stay where we need to make Ohmic contact. We would remove the excess aluminum (i.e., “Lifted Off’) by soaking the samples in the Acetone filled beaker. The acetone will cause the PR+ to swell and thus dislodge or liftoff when placed in an ultrasonic cleaner. An ultra-sonic cleaner is a device where the sample is shaken at ultrasonic frequency. This helps acetone to penetrate into the thin films of metal and react with photoresist. When the photoresist dissolves into acetone, the space between the metal and silicon is empty and the ultrasonic frequency forces Aluminum metal to sheer off. In 5-10 minutes all the Aluminum that was deposited over the photoresist is removed. The part that had no photoresist retains Al. It is this part that needs Ohmic contact and needs alloying to implement this. Questions – 15 1. Why is vacuum needed to deposit the metal? 2. What role does melting point of the metal play in the metal deposition? 3. In the current IC technology what material is used for the contacts? 16