Name: Ethylene Oxide - International Council of Chemical

advertisement

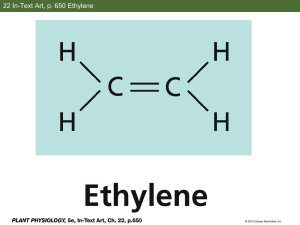

AkzoNobel Functional Chemicals AB Ethylene Amines Product Stewardship Summary (PSS) Ethylene Oxide SUBSTANCE NAME Ethylene Oxide GENERAL STATEMENT This Product Safety Summary document is to provide product safety and end use information on this product. It is not intended to provide emergency response, medical or treatment information, or to provide a discussion of all safety and health information. This document is not intended to replace the Material Safety Data Sheet or Safety Data Sheet which should be consulted before use of the chemical. CHEMICAL IDENTITY Name: Ethylene Oxide Synonyms: EO, Oxirane Chemical name: Ethylene Oxide CAS number: 75-21-8 Molecular formula: C2H4O USES AND APPLICATIONS AkzoNobel manufactures EO and other ethylene amines at their facilities in Stenungsund, Sweden and Ningbo, China. Ethylene Amines are particularly reactive molecules making them a versatile tool for building new molecules for a wide range of applications. They have the ability to change the properties of chemical products, making them softer, firmer, or more supple. They can prevent coagulation or increase flow. Ethylene oxide is a key ingredient in the manufacturing of ethylene amines. Ethylene amines are manufactured using main raw materials ethylene, oxygen, and ammonia. They are produced when monoethanolamine and ammonia react under high pressure and at a high temperature in the presence of hydrogen and a catalyst. EO is a cyclic ether composed of two alkyl groups connected to an oxygen atom. Ethylene oxide is used industrially to make many consumer products as well as non-consumer chemicals and intermediates. It is industrially produced by direct oxidation of ethylene in the presence of a silver catalyst. EO has applications in the production of solvents, antifreeze, textiles, detergents, adhesives, polyurethane foam, and pharmaceuticals. Other applications include manufacture of Ethylene glycol, polyglycols, ethanolamines, and cellulose ethers. Smaller applications of EO include in fumigants, sterilants for spices and cosmetics, as well as during hospital sterilization of surgical equipment. PHYSICAL/CHEMICAL PROPERTIES EO is a clear colorless liquid with a sweet odor. EO is miscible in water, ethanol, acetone, ether, benzene, and hexane. EO is an extremely flammable substance, even at room temperature. Property Form Physical State Colour Odour Density Melting Boiling Point Flammability Explosive Properties Self-ignition temperature Vapor pressure Mol weight Water solubility Flash Point Octanol-water partition coefficient (LogPow) Value It is a clear colorless liquid with a sweet odor. Liquid Clear Colorless Sweet 890 kg/m3 at 0°C -113.3°C 10.5°C Extremely No 429°C 1,752 hPa (at 25°C) 44.05 Miscible at 20°C -57°C Log Pow: -0.3 HEALTH EFFECTS Primary routes of exposure are skin contact, eye contact, and inhalation. EO is a skin irritant and may degrease the skin. It can be absorbed through the skin and may lead to dermatitis. This product can cause serious eye irritation. EO is toxic through inhalation and is irritating to the respiratory system. Inhalation of aerosols may cause irritation to the mucous membranes. If ingested, this product can cause severe irritation of the throat, esophagus, and stomach. Persons with pre-existing skin and/or respiratory disease may be at increased risk if exposed to this material. EO is listed as a category 2 carcinogen and is carcinogenic to man. EO is mutagenic according to Ames test and has reproductive toxicity. EO may cause cancer and heritable genetic damage, based on animal studies. Consumer and worker exposure is very unlikely as this substance is manufactured and handled in industrial settings in closed systems. AkzoNobel is dedicated to designing, constructing and maintaining production and handling systems that eliminate exposure to EO. ENVIRONMENTAL EFFECTS The environmental exposure of EO is not harmful to the environment, but may be harmful to aquatic life. EO breaks down rapidly when released into the environment and does not persist long in the environment. EO is readily biodegradable and is not expected to bioaccumulate due to the low log Pow value. EO will dissolve in water and absorption to the solid soil particles is not expected. This substance is not considered to be a PBT or vPvB (Persistent, Bioaccumulative, Toxic or very Persistent nor very Bioaccumulating). SPECIAL CONSIDERATIONS As indicated, harmful exposure effects of EO to the body are worth noting. EO is extremely toxic and flammable. Proper PPE should be used when handling EO. Keep away from sunlight, sources of ignition, static discharge and don’t expose to temperatures exceeding 50 °C. Elevated temperatures can cause ignition leading to thermal decomposition and release of hazardous gases. For these reasons AkzoNobel provides training and information to users of EO and to emergency responders. EXPOSURE Consumers will not come into contact with EO as it is manufactured in a closed process which also minimizes employee exposure potential. Exposure to EO in the environment or personnel in manufacturing facilities is also considered very low because the process, storage and handling operations are enclosed. In general, obtain medical attention immediately if there is any exposure to EO on the skin, eyes, inhalation, or ingestion. AkzoNobel takes great effort to prevent accidents of any kind related to EO. Strict controls are in place to avoid worker exposure including the use of personal protective equipment and redundant safety systems. Any EO leaks or spills should only be handled by trained emergency response personnel wearing the appropriate PPE (Protective suit and boots, Butyl rubber gloves, tightly fitted splash goggles, and a NOISH approved positive-pressure demand, self-contained breathing apparatus). RISK MANAGEMENT RECOMMENDATIONS Engineering Controls EO must be handled and stored in a properly designed environment. Avoid contact with skin, eyes, direct inhalation or ingestion. Sufficient natural or mechanical exhaust ventilation must be provided at all times to help minimize exposure level. If ventilation is not adequate, use a NIOSH approved organic vapor acid gas (OVAG) respirator with dust, mist, and fume filter to reduce exposure. Containers should be kept tightly capped and stored in a cool, dry, well-ventilated area away from incompatible materials, sources of heat, flame, or direct sunlight. Ensure that eyewash stations and safety showers are easily assessable. Please consult MSDS for specific control measures to be taken. Personal Protective Equipment Protective suit and boots, Butyl rubber gloves, and chemical safety splash goggles or face shield are recommended. Use a NOISH approved organic vapor respirator with dust, mist, and fume filters. If a higher level of protection is needed, use a NIOSH-approved positive pressure demand, air-supplied respirator. When using respirator cartridges or canisters, they must be changed frequently. Please contact AkzoNobel for specific recommendations on PPE. PRODUCT STEWARDSHIP CONSIDERATION AkzoNobel takes great care in the production, handling, and transport of this product. It is our highest priority in making sure they are safe for our employees and for our neighbors. We have been certificated in accordance with the ISO 14001 Environmental Management System since 1999, certificated in accordance with ISO 9001, and SS 627750 Energy certified. We offer safety data sheets containing information on properties, handling, precautions, and firstaid procedures. We offer an Ethylene Best Practices Manual, giving more detailed recommendations on the proper use and handling of ethylene amine products. Life Cycle Assessment documentation on our products is available on request. We have also adopted the principles of the chemical industry’s Responsible Care program for continuous improvement in the aspects of health, safety, and environment. Potential risks from the plant and from transport of hazardous goods are investigated and monitored. These investigations are followed up and risk reducing measures are implemented. We employ intermodal transport to transport the load effectively, both from an environmental and economic perspective. In addition, emissions to water from the site have been reduced substantially as a result of a larger share of process water being incinerated, and by improving procedures and equipment. REFERENCES / AGENCY FINDINGS AkzoNobel Ethylene Amines Safety Data Sheets (Europe, Asia, South America, Africa) AkzoNobel Ethylene Amines Product Information http://www.osha.gov/OshDoc/data_General_Facts/ethylene-oxide-factsheet.pdf http://www.atsdr.cdc.gov/toxfaqs/tf.asp?id=733&tid=133 REGULATORY INFORMATION / CLASSIFICATION AND LABELING Transport EO is regulated for transport by the ADR, RID, IMDG, and IATA. It is classified as a toxic flammable substance and is listed in the Hazardous Materials Table under UN number 1040. Flammable and toxic labels are required for transport. Worker Safety Some Occupational Exposure Limits have been established by international organizations for the safe handling of EO in the workplace. Proper engineering controls, personal protective equipment and workplace exposure monitoring must be followed to adhere to these standards. Use and Disposal Do not dispose of waste in sewer systems. Do not contaminate ponds, waterways, or ditches with chemical or used container. Remaining contents should be emptied accordingly and empty drum shouldn’t be burned. The use and disposal of EO are subject to various international laws and regulations. In the EU, EO is subject to REACH regulations. Additional regulations may exist that govern the manufacture, sale, transportation, use and/or disposal of EO. These regulations may vary by city, state, country or geographic region. Additional helpful information may be found by consulting the relevant Material Safety Data Sheet. CONCLUSION o o o EO has major applications in the manufacture of Ethylene glycol, polyglycols, ethanolamines, and cellulose ethers among other applications. EO is extremely toxic and flammable. Avoid ignition sources and elevated storage temperatures which may lead to thermal decomposition and release of toxic gases. Exposure to EO can cause harmful health effects and should therefore be avoided. AkzoNobel goes above and beyond industry standards and regulations to help ensure safe manufacture, transportation, and use of EO. CONTACT INFORMATION WITHIN COMPANY Via Telephone o o o For product and technical information: +4630385000 For Chemical Emergencies (Spill, Leak, Exposure, Fire, Accident): +31 570679211 For medical or handling emergencies: +31 570679211 (Fax +31 570679801) AkzoNobel, Chemicals, Deventer, NL Via the Internet o www.akzonobel.com/ea DATE OF ISSUE/REVISION September 21, 2011 China: 0532 83889090 DISCLAIMER AkzoNobel is a member of the American Chemistry Council (ACC), which represents the leading companies engaged in the business of chemistry. ACC’s member companies, through ACC’s participation with the International Council of Chemical Associations (ICCA), are actively engaged with the Global Product Strategy (GPS). GPS, which is designed to meet United Nation's Strategic Approach to Chemicals Management, is an innovative program to improve product stewardship within the chemical industry and with suppliers and customers throughout the chain of commerce. Companies engaged in GPS, including AkzoNobel, are committed to make relevant product stewardship information on chemicals in commerce publicly available. The summaries provided here are AkzoNobel’s contributions to that effort. GLOSSARY ADR - European Agreement concerning the International Carriage of Dangerous Goods by Road. The ADR regulates the international transport of dangerous goods. A European directive means that the ADR also applies to the domestic transport in the affiliated countries. Hygroscopic – taken up and retained under some conditions of humidity and temperature. IATA - International Air Transport Association is an international industry trade group of airlines headquartered in Montreal, Quebec, Canada IMDG - International Maritime Dangerous Goods Code is accepted as an international guideline to the safe transportation or shipment of dangerous goods or hazardous materials by water on vessel. MSDS - Material Safety Data Sheets, a form with data regarding the properties of a particular substance, which includes but not limited to toxicity, health effects, first aid, reactivity, storage, disposal, protective equipment, and spill handling procedures. NIOSH - The National Institute for Occupational Safety and Health (NIOSH) is the federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. REACH - the regulation on Registration, Evaluation, Authorization, and Restriction of Chemicals of the European Union (EU). REACH ensures a high level of protection of human health and the environment from the risks that can be posed by chemicals. RID - Regulation concerning the International Carriage of Dangerous Goods by Rail. The RID applies to the international transport of dangerous goods by rail. The affiliated countries come to a mutual agreement as discussed above for the ADR. SDS- Safety Data Sheet, a form with data regarding the properties of a particular substance, which includes but not limited to toxicity, health effects, first aid, reactivity, storage, disposal, protective equipment, and spill handling procedures. For Europe also include exposure scenario (e-SDS)