pubdoc_10_22480_1454

advertisement

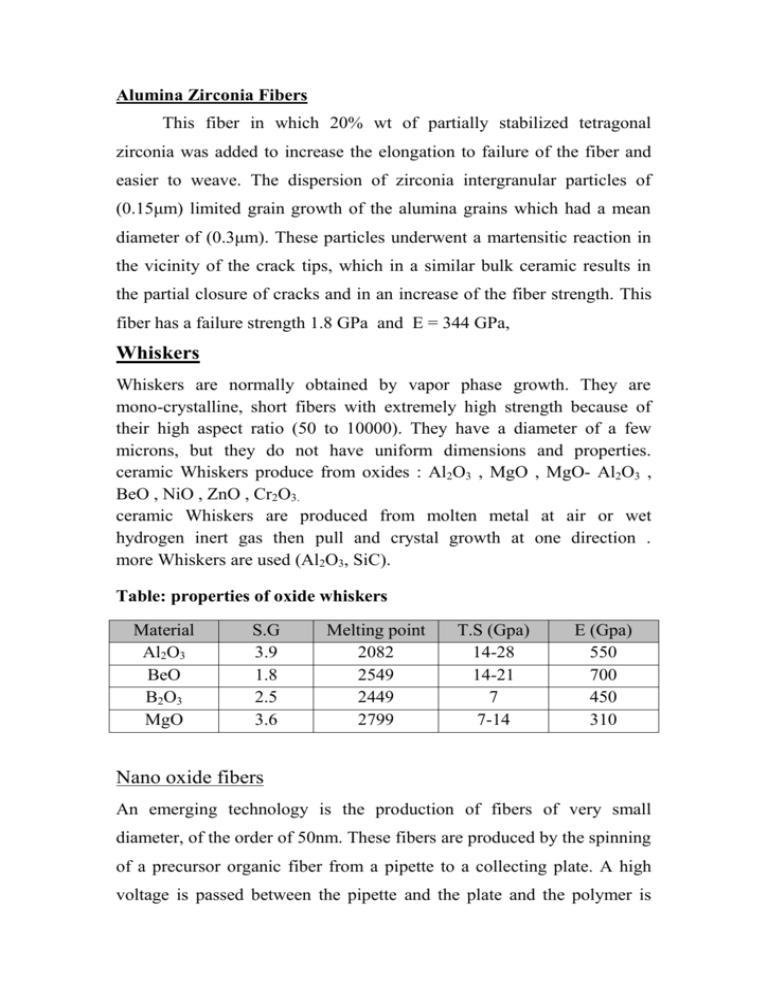

Alumina Zirconia Fibers This fiber in which 20% wt of partially stabilized tetragonal zirconia was added to increase the elongation to failure of the fiber and easier to weave. The dispersion of zirconia intergranular particles of (0.15μm) limited grain growth of the alumina grains which had a mean diameter of (0.3μm). These particles underwent a martensitic reaction in the vicinity of the crack tips, which in a similar bulk ceramic results in the partial closure of cracks and in an increase of the fiber strength. This fiber has a failure strength 1.8 GPa and E = 344 GPa, Whiskers Whiskers are normally obtained by vapor phase growth. They are mono-crystalline, short fibers with extremely high strength because of their high aspect ratio (50 to 10000). They have a diameter of a few microns, but they do not have uniform dimensions and properties. ceramic Whiskers produce from oxides : Al2O3 , MgO , MgO- Al2O3 , BeO , NiO , ZnO , Cr2O3. ceramic Whiskers are produced from molten metal at air or wet hydrogen inert gas then pull and crystal growth at one direction . more Whiskers are used (Al2O3, SiC). Table: properties of oxide whiskers Material Al2O3 BeO B2O3 MgO S.G 3.9 1.8 2.5 3.6 Melting point 2082 2549 2449 2799 T.S (Gpa) 14-28 14-21 7 7-14 E (Gpa) 550 700 450 310 Nano oxide fibers An emerging technology is the production of fibers of very small diameter, of the order of 50nm. These fibers are produced by the spinning of a precursor organic fiber from a pipette to a collecting plate. A high voltage is passed between the pipette and the plate and the polymer is drawn from the pipette to the plate. The fibers are generally collected on the plate to form a random array although work is proceeding to align the fibers. The fibers are too fine to be tested by conventional techniques but can be tested as bundles. At present this technology is still at the laboratory stage so that few data are available however the nano-metric diameter could be expected to confer on the filaments perhaps exceptional properties which are not obtained with larger diameter fibers. This is primarily because dislocation movement should be restricted so that high strengths and low creep rates could be expected. At the laboratory scale oxide fibers such as Al2O3, ZrO2 and TiO2 as well as carbon fibers have been made but they are far from having being fully evaluated. Non oxide fibers A) Silicon carbide Continuous SiC fibers were produced by thermal degradation of a polymer precursor such as a polycarbosilane to from a continuous fiber is made by melt-spinning. The fiber is then converted by pyrolysis at 1300°C into a fiber consisting mainly of( β-SiC) of about 15µm diameter. The characteristic commercial fiber of this type is that known as 'Nicalon' . It has a rough surface, making for good fiber/matrix adhesion, but is somewhat reactive towards oxygen. It is well wetted by molten metals and is reasonably stable as a reinforcement for MMCs based on aluminum and copper although it lacks long-term thermal stability. There have been various attempts to improve this feature of the fiber, for example by reducing the oxygen content and by adding titanium. Methods of manufacturing SiC fibers 1) SiC fibers via polymers The SiC fiber obtained via CVD is very thick and not very flexible. By an alternative route, very fine, continuous and flexible fiber was obtained by using a process of controlled pyrolysis of polymeric precursor. The ceramic fibers produced by this process good mechanical properties; good thermal stability and oxidation resistance have enormous potential for the development of ceramic matrix composites. 2) SiC fibers via CVD Silicon carbide (SiC) fibers are produced by using (methel trichloro siliane) where it is deposited on fine grain shape with diameter (100nm). This fibers have strength (6 Gpa) but very stiff and difficult to forming . B) boron carbide and boron nitride There are other promising ceramic fibers, e.g. boron carbide and boron nitride. Boron nitride fiber has the same density (2.2 g /cm3) as carbon fiber, but has a greater oxidation resistance and excellent dielectric properties .Boron carbide fiber is a very light and strong material. C) Carbon fibers By oxidizing and pyrolysing a highly drawn textile fiber preventing it from shrinking in the early stages of the degradation process, and subsequently hot-stretching it, it is possible to convert it to a carbon filament with an elastic modulus that approaches the value we would predict from a consideration of the crystal structure of graphite, although the final strength is usually well below the theoretical strength of the carbon-carbon chain. The influence of strength-limiting defects is considerable, and clean-room methods of production can result in substantial increases in the tensile strength of commercial materials. Prior to sale, fibers are usually surface-treated by chemical or electrolytic oxidation methods in order to improve the quality of adhesion between the fiber and the matrix in a composite. Depending on processing conditions, a wide range of mechanical properties (controlled by structural variation) can be obtained, and fibers can therefore be chosen from this range so as to give the desired composite properties. Although the fiber is highly organized and graphite-like, the structure is not identical with that of graphite and the fibers should not, strictly speaking, be referred to by that name. Recent developments in this field have led to the use of pitch as a precursor in place of textile fibers, and these newer materials have extremely high stiffness, but rather lower strengths . Properties of carbon fibers 1. High modulus. 2. Good strength. 3. Good thermal stability in the absence of O2 4. High thermal conductivity, assisting good fatigue properties 5. Low thermal expansion coefficient 6. Excellent creep resistance 7. Good chemical resistance . 8. Low electrical resistivity The disadvantages are: 1. Relatively high cost, but prices have been falling and more emphasis is now placed on using large tows 2. Low strain to failure with attendant handling problems 3. Compressive strength is lower than tensile strength and larger diameter fiber does not give improved compression properties 4. Poor impact strength of composites 5. Care required during handling carbon fiber, since it is electrically conducting and can cause havoc with electrical systems 6. Oxidizes in air at temperatures above 450 C˚. 7. Exhibits anisotropy in the axial and transverse directions.