[7] Kim JY, Lee K., Coats NE, Moses D., Nguyen TQ, Dante M

advertisement

![[7] Kim JY, Lee K., Coats NE, Moses D., Nguyen TQ, Dante M](http://s3.studylib.net/store/data/006602619_1-c879705532632341dc33db4ea732b9cd-768x994.png)

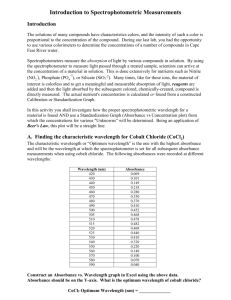

Absorbance/Transmittance/Reflectance of PCDTBT:PC70BM Organic Blend Layer Rashmi Swami*, Rajesh Awasthy, B.P.Chandra and Sanjay Tiwari Photonics Research Laboratory School of Studies in Electronics , Pt. Ravishankar Shukla University, Raipur(C.G.) 492010 India Email: rashmi.swami3@gmail.com ABSTRACT In this paper we are investigating the optical properties of photoactive layer consisting of blend of PCDTBT (an electron donor) PC70BM (an electron acceptor). Using MATLAB coding for cumulative and net radiation method of multilayer structure we investigated absorbance, transmittance, reflectance spectra and their variation with wavelength. Both methods are equivalent ( both will give same result) and they take into account the effect of multiple reflections. Refractive index, extinction coefficient, absorbance of PCDTBT:PC70BM blend film shows variations in visible range (350 nm - 650 nm). Refractive index of PCDTBT:PC70BM increases from wavelength 450 nm to 612 nm and reaches to its maximum value 2.2883 at 610 nm wavelength. Extinction coefficient of PCDTBT:PC70BM has maximum value of 0.4408 at 300 nm wavelength then decreases with increase in wavelength. The PCDTBT:PC 70BM PV film showed strong absorption bands in the visible range from 350 to 650 nm, extending to an absorption onset at 800 nm, and containing two distinct but broad absorption bands centered at ca. 380-420 nm and ca. 475-570 nm. Reflectance is less than 17% in visible and infrared region. Blend layer shows more than 50% transmittance at wavelengths longer than 570 nm i.e. transmittance is high in infrared region and sharp fall below 350 nm because of strong absorbance in this region. Keywords- PCDTBT:PC70BM, absorbance, transmittance, reflectance, refractive index. I. INTRODUCTION Sun is a huge source of renewable energy that can be converted into electrical energy using solar cells. Organic materials, particularly polymers, are a promising alternative to traditional semiconductors as the active material for solar cell because of their low cost, low temperature & energy processing, low material requirement, can be used on flexible substrate, can be shaped to suit architectural application. The key development of organic solar cells has been made with the pioneering concept of ‘‘bulk heterojunction (BHJ)’’ photoactive layers [1][2].The bulk heterojunction (BHJ) PSC [1][3-7] is of particular interest, due to the efficient photo-induced generation of charge in its blended photovoltaic (PV) layer, which is composed of interpenetrating, channel-like domains of separated polymer and fullerene phases. Recently, as an alternative, poly[N-9’’-hepta-decanyl-2,7carbazole-alt-5,5-(4’,7’-di-2-thienyl-2’,1’,3’- benzothiadiazole)] (PCDTBT) and [6,6] -phenyl C70-butyric acid methyl ester (PC70BM) based organic solar cells have received intensive study due to higher energy conversion efficiency of more than 6% [8]. This is due to a better alignment of molecular orbital energy levels between the PCDTBT polymer and the PCBM fullerene. A. Donor molecule Poly[[9-(1-octylnonyl)-9H-carbazole-2.7-diyl]-2.5-thiophenediyl2.1.3 benzothiadiazole-4.7-diyl-2.5-thiophenediyl] (PCDTBT) shown in Fig. 1. is one of the next generation donor materials. The key properties of PCDTBT over standard organic photovoltaic materials (such as P3HT) : lower HOMO and LUMO levels narrow band gap Increased open circuit voltage Longer wavelength absorption Lower concentration and material usage Improved stability under ambient conditions High electron and hole generation rate and high mobility of electron and hole. Fig. 1. Molecular structure of PCDTBT. B. Acceptor molecule Fullerenes are highly symmetrical cage-shaped molecules constituted only by carbon atoms, which have been thoroughly studied during the last two decades [9]. Blending conjugated polymers with electron acceptors such as fullerenes, is a very efficient way to break apart photoexcited excitons into free charge carriers. The fullerene PCBM core readily accepts electrons from a wide range of organic donor materials and exhibits high electron mobilities even in composite form. In this study, we used the soluble PC70BM, the chemical structure of which is shown in Fig.2. Fig. 2. Molecular structure of PC70BM. 𝜂 = In this paper we investigated optical properties of photoactive blend layer of PCDTBT:PC70BM on glass substrate. II. EXPERIMENTAL WORK Vacuum evaporation and solution processing techniques are the most commonly used thin film preparation methods in the fabrication of organic solar cells. Since polymers decompose under excess heat, most photovoltaic polymers are solution processed films through spin coating. During the process of spincoating, an excess amount of the D/A (Donor/Acceptor) blend solution is dropped on the substrate, which is then rotated at a high speed in order to spread the fluid by centrifugal force. Solutions of D/A blends can be prepared by dissolving donor and acceptor materials in a common solvent. The blend films in this study were all prepared by spin-coating method. As shown in Fig.3. above glass substrate the photoactive layers were spin-cast at 500–3000 rpm by using a blend solution of PCDTBT (7 mg/ml) and PC70BM (28 mg/ ml) dissolved in 1,2 dichlorobenzene (oDCB). The BHJ films were dried at 60 degree centigrate (40 min) to remove the solvent. Using MATLAB we obtained the graph of absorbance, transmittance, reflectance. N/ cos 𝜙 for p-polarized irradiance, N cos 𝜙 for s-polarized irradiance. Here 𝜂1 is determined using N1 and 𝜙1 and 𝜂2 is determined using N2 and 𝜙2 . The reflection coefficient depends on the polarisation state of light. Direct sunlight is generally considered to be unpolarised [11], i.e. it contains equal amounts of p- and spolarised irradiance. The fraction of energy in the refracted (transmitted) beam is simply given by t=1-r (2) B. Reflection and refraction at a coated interface The reflection coefficient of the interface between medium 1 and 2 can be reduced significantly if a thin coating is added to the interface. This coating is characterized by a thickness dc and a refractive index Nc = nc−ikc. The coating is considered to be thin if its optical thickness (ncdc) is smaller than the coherence length of the incident light, which is approximately 1 μm for solar irradiance [11]. If the refractive index of the coating lies in between the refractive indices of the neighbouring media, then the reflection coefficient of the combination of the coating and the underlying medium is given by- r=| 𝜂1 − 𝑌 2 𝜂1 + 𝑌 | (3) where Y can be interpreted as the ‘effective refractive index’ of this combination [10], given by- Y= 𝜂2 cos 𝛿+ 𝑖𝜂𝑐 sin 𝛿 𝜂 cos 𝛿+ 𝑖( 2⁄𝜂𝑐 ) sin 𝛿 (4) Phase difference 𝛿 is given by – 𝛿= Fig. 3. Structure of PCDTBT:PCBM blend over glass substrate Where n1 = refractive index of first medium(medium 0) air = 1. n2 = refractive index of PCDTBT:PC70BM blend (medium 1). k2 = extinction coefficient of PCDTBT:PC70BM blend (medium 1) . 2𝜋𝑁𝐶 𝑑𝑐 𝜆 cos 𝜙𝑐 (5) where 𝜆 is the (vacuum) wavelength of the irradiance and the angle of refraction in the coating 𝜙𝑐 is given by Snell’s law. C. A system with two interfaces As shown in Fig. 4, there are three media involved (labelled 0, 1 and 2), separated by two interfaces (labelled 1 and 2). Each medium is characterised by a complex refractive index N ( N = n – ik , where n is the real refractive index and k is the extinction coefficient). The first and final media are semi-infinite, medium 1 (or layer 1) is characterized by a thickness d1. n3 = refractive index of glass substrate (medium 2) = 1.5. III. CACULATION METHODS Here we are explaining different methods for the calculation of absorbance, transmittance, reflectance of layer. A. Reflection and refraction at an uncoated interface First the most simple interface, without coating, is considered. Using a notation similar to Macleod’s [10], the reflection coefficient is given by r=| η1− η2 2 η1+η2 | (1) where 𝜂 is the modified refractive index given by Fig. 4. A cross-section of a simple multilayer system containing two interfaces. Left: the internally reflecting sub-rays considered in the cumulative method are indicated. Right: the net-radiation fluxes considered in the net-radiation method are indicated. Assuming specular reflection and a given angle of incidence ø 0, the reflection coefficients r1 and r2 of interfaces 1 and 2, respectively, can be determined. Normal incidence is considered here. The transmission coefficient 𝜏1 of layer 1 is defined as the fraction of irradiance remaining after a single passage through this layer 𝜏1 = 𝑒 −𝛼1 𝑑1/𝑐𝑜𝑠 ø1 (6) where d1/ cos ø1 is the distance the ray has traversed in the layer. d1(150 nm) is thickness of blend layer. Angle ø1 is calculated using Snell’s law – n1 sin ø0 = n2 sin ø1 (7) For a non-absorbing layer 𝜏 = 1 and for an opaque layer 𝜏 = 0. Two methods for determining the spectral absorption factor Aλ of the system as a whole will be presented. Both methods are equivalent and they take into account the effect of multiple reflections, indicated in Fig. 4. 1) Cumulative method: The most straightforward strategy is to follow (trace) an incoming ray of light as sketched in the left panel of Fig. 4. At the interfaces the ray will split up in a reflected and refracted sub-ray and multiple internal reflections occur between the two interfaces. In order to determine the factors RC, AC and TC accurately, the contribution of each sub-ray has to be considered. The infinitely many contributions can be expressed as a geometric series – RC = r1+ 𝑡12 𝜏12 𝑟2 (1−𝑟1 𝑟2 𝜏12 ) TC = 𝑡1 𝜏1 𝑡2 ∑∞𝑛=0(𝑟1 𝑟2 𝜏12 )𝑛 TC = (8) (1−𝑟1 𝑟2 𝜏12 ) (10) where r and t are the reflection and transmission coefficients of the interfaces (equation 1 &2) and 𝜏 is the transmission coefficient of the layer (equation 6) . 2) Net-radiation method: Another strategy is to group the infinitely many sub-rays into net-radiation fluxes as indicated in the right panel of Fig.4. There are four fluxes (labelled a, b, c and d) per interface. For example flux q1b contains all sub-rays travelling away from interface 1 in the upward direction. Because each flux contains the net-radiation, this method is called the netradiation method [12]. It is convenient to consider the fluxes to be non-dimensional and to normalise the incident flux, i.e. q 1a = 1. Further it is assumed that no irradiance is incident from below the multilayer structure, i.e. q2c = 0. It can be checked that the fluxes are related in the following way – q1a = 1 q1b = r1q1a + t1q1c q1c = 𝜏1q2b q1d = r1q1c + t1q1a q2a = 𝜏1q1d q2b = r2q2a + t2q2c q2c = 0 q2d = r2q2c + t2q2a (12) 𝑇𝑛 = 𝑞2𝑑 (13) 𝐴𝑛 = 𝑞1𝑑 − 𝑞2𝑎 + 𝑞2𝑏 − 𝑞1𝑐 (14) Note that this method is equivalent with the cumulative method, but it has the advantage that the individual sub-rays do not need to be considered. IV. RESULTS AND DISCUSSION The complex indices of refraction were measured by spectroscopic ellipsometry and used to describe optical transmission, reflection, absorption characteristic of photoactive blend layer. Fig.5 shows the variation of refractive index and extinction coefficient of PCDTBT:PC70BM with wavelength. Refractive index of PCDTBT:PC70BM increases from wavelength 450 nm to 612 nm and reaches to its maximum value 2.2883 at 610 nm wavelength. Extinction coefficient of PCDTBT:PC70BM has maximum value of 0.4408 at 300 nm wavelength then decreases with increase in wavelength. (9) 𝑡1 𝜏1 𝑡2 AC = 1-RC-TC 𝑅𝑛 = 𝑞1𝑏 (11) refractive index and extinction coefficient of PCDTBT:PCBM RC = r1+t12 𝜏12 r2 ∑∞𝑛=0(𝑟1 𝑟2 𝜏12 )𝑛 By solving this set of linear equations, the fluxes are found and the spectral reflection, absorption and transmission factors can be found directly graph of refractive index and extinction coefficient of PCDTBT:PCBM 2.5 n2 k2 2 1.5 1 0.5 0 -0.5 300 400 500 600 700 800 Lambda (nm) 900 1000 1100 1200 Fig. 5. Refractive index and extinction coefficient of PCDTBT:PC70BM. We calculated reflectance, transmittance and absorbance using cumulative method from equations (8,9,10) and using net radiation method from equations (12,13,14). From both the methods we got the same graph for absorbance, transmittance and reflectance with respect to wavelength. Absorbance graph shown in Fig.6 using cumulative method and in Fig.7 using net radiation method show that the PCDTBT:PC70BM PV film showed strong absorption bands in the visible range from 350 to 650 nm, extending to an absorption onset at 800 nm, and containing two distinct but broad absorption bands centered at ca. 380-420 nm and ca. 475-570 nm. The two broad absorption bands with peaks at 398 and 576 nm were caused by the PCDTBT, and the absorption near 450 nm was caused by the PC70BM. The Absorbance graph of PCDTBT:PCBM using cumulative method 0.9 Ac (absorbance for 150nm thickness) 0.8 0.7 Absorbance (Ac) 0.6 Transmittance (Tc) and Reflectance (Rc) two broad absorption bands with peaks at 398 and 576 nm were caused by the PCDTBT, and the absorption near 450 nm was caused by the PC70BM. Transmittance and Reflectance graph of PCDTBT:PCBM using cumulative method 0.9 0.8 0.7 0.6 0.5 0.4 Tc(transmittance for 150nm thickness) Rc(Reflectance for 150nm thickness) 0.3 0.2 0.1 0.5 0 300 0.4 400 500 600 0.3 700 800 Lambda (nm) 900 1000 1100 1200 0.2 Fig.8. Transmittance and Reflectance versus wavelength of incident radiation using cumulative method . 0.1 0 400 500 600 700 800 Lambda (nm) 900 1000 1100 1200 Transmittance and Reflectance graph of PCDTBT:PCBM using net radiation method 0.9 Transmittance (Tn) and Reflectance (Rn) -0.1 300 Fig. 6. Absorbance versus wavelength of incident radiation using cumulative method. Absorbance graph of PCDTBT:PCBM using net radiation method 0.9 An (absorbance for 150nm thickness) 0.8 0.7 Absorbance (An) 0.6 0.5 0.8 0.7 0.6 0.5 0.4 0.3 Tn(transmittance for 150nm thickness) Rn(Reflectance for 150nm thickness) 0.2 0.1 0.4 0 300 0.3 400 500 600 700 800 Lambda (nm) 900 1000 1100 1200 0.2 0.1 Lambda 0 -0.1 300 400 500 600 700 800 Lambda (nm) 900 1000 1100 1200 Lambda (nm) Fig. 7. Absorbance versus wavelength of incident radiation using net radiation method. Fig.8 (using cumulative method) and Fig.9 ( using net radiation method) show variation of transmittance and reflectance of PCDTBT:PC70BM with wavelength. Blend layer shows more than 50% transmittance at wavelengths longer than 570 nm i.e. transmittance is high in infrared region and sharp fall below 350 nm because of strong absorbance in this region. Reflectance is less than 17% in visible and infrared region. Fig.9. Transmittance and Reflectance versus wavelength of incident radiation using net radiation method . V. CONCLUSION We investigated the optical properties of photoactive layer consisting of blend of PCDTBT (an electron donor) PC70BM(an electron acceptor) using cumulative and net radiation method. Photoactive blend layer properties investigated include their refractive index, extinction coefficient, absorbance/transmittance/reflectance spectra and their variation with wavelength. Graph of absorbance/transmittance/reflectance of PCDTBT:PC70BM photoactive blend layer with wavelength is obtained using MATLAB coding for cumulative and net radiation method. Refractive index, extinction coefficient, absorbance of PCDTBT:PC70BM blend film shows variations in visible range (350 nm - 650 nm). Refractive index of PCDTBT:PC70BM increases from wavelength 450 nm to 612 nm and reaches to its maximum value 2.2883 at 610 nm wavelength. Extinction coefficient of PCDTBT:PC70BM has maximum value of 0.4408 at 300 nm wavelength then decreases with increase in wavelength. The PCDTBT:PC70BM PV film showed strong absorption bands in the visible range from 350 to 650 nm, extending to an absorption and conductivity onset at 800 nm, and containing two distinct but broad absorption bands and conductivity band centered at ca. 380-420 nm and ca. 475-570 nm. Blend layer shows more than 50% transmittance at wavelengths longer than 570 nm i.e. transmittance is high in infrared region and sharp fall below 350 nm because of strong absorbance in this region. Reflectance is less than 17% in visible and infrared region. REFERENCES [1] Yu G., Gao J., Hummelen J.C., Wudl F., Heeger A.J.,” Polymer Photovoltaic Cells: Enhanced Efficiencies via a Network of Internal Donor-Acceptor Heterojunctions ”, Science, New Series, vol. 270, No. 5243,(1995), 1789-1791 . [2] Halls J.J.M., Walsh C.A., Greenham N.C., Marseglia E.A., Friend R.H., Moratti S.C., Holmes A.B., “Efficient photodiodes from interpenetrating polymer networks ”, Nature 376, ( 1995), 498–500. [3] Brabec C.J., Sariciftci N.S., and Hummelen J.C.,” Plastic Solar Cells ”, Adv. Funct. Mater. 11(1), ( 2001), 15–26. [4] Peet J., Kim J.Y., Coates N.E., Ma W.L., Moses D., Heeger A.J. and Bazan G.C.,” Efficiency enhancement in lowbandgap polymer solar cells by processing with alkane dithiols ” Nat. Mater. 6, (2007), 497-500. [5] Yang F., Shtein M. and Forrest S.R., “ Controlled growth of a molecular bulk heterojunction photovoltaic cell”, Nat. Mater.4, (2005),37-41. [6] Kim J.Y., Kim S.H., Lee H., Lee K., Ma W., Gong X., and Heeger A.J., “New Architecture for High-Efficiency Polymer Photovoltaic Cells Using Solution-Based Titanium Oxide as an Optical Spacer ”,Adv. Mater.18, (2006), 572-576. [7] Kim J.Y., Lee K., Coats N.E., Moses D., Nguyen T.Q., Dante M., Heeger A.J., “Efficient tandem polymer solar cells fabricated by all-solution processing ”, Science 317, (2007), 222-225. [8] Park S.H., Roy A., Beaupre S., Cho S., Coates N., Moon J.S., Moses D., Leclerc M., Lee K., and Heeger A.J., “Bulk heterojunction solar cells with internal quantum efficiency approaching 100% ”, Nat. Photonics 3(5), (2009), 297–302. [9] Sun Y., Takacs C.J., Cowan S.R., Seo J.H., Gong X., Roy A., Heeger A.J., “Efficient, Air-Stable Bulk Heterojunction Polymer Solar Cells Using MoOxas the Anode Interfacial Layer”, Adv. Mater. 23, (2011), 2226–2230. [10] Macleod, H.A., “Thin-film optical filters”, Adam Hilger Ltd, Bristol, 2 ed., (1986). [11] Hecht E., Optics. Addison Wesley Longman, Inc., 4 ed., (2002). [12] Siegel, R., “Net radiation method for transmission through partially transparent plates”, Solar Energy, vol. 15, (1973) , 273–276.