Project Fact Sheet - Electrical and Computer Engineering

advertisement

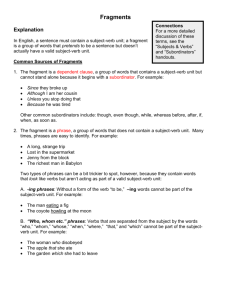

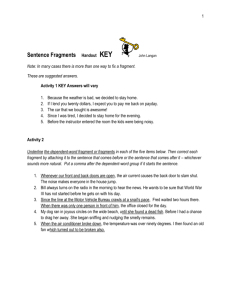

z US ARMY AMRDEC FRAGMENT SCANNING SYSTEM| PROJECT FACT SHEET OBJECTIVE A scanning system to determine location and size of metal fragments embedded in a medium density fiber panel. BACKGROUND As part of its many scientific efforts, the Weapons Integration and Development Directorate (WDI) of the US Army Aviation and Missile Research, Development, and Engineering Center (AMRDEC) performs a variety of explosive and warhead research and development activities. When testing explosive charges, a typical method of recording fragmentation parameters uses stacks of fiber panels (bundles) placed around the charge. Upon detonation, fragments embed themselves in the bundles at various depths and orientation. The bundles are then disassembled layer by layer. Each layer is then searched by hand for fragments with a rare earth magnet. The X/Y position of the fragment is then measured and recorded, and the fragment is removed from the bundle, identified, bagged, and tagged. The fragments are later cleaned and weighed. The sheet from which the fragment was removed is used as a measurement of depth of penetration. The key measurement criteria are: position, depth, and mass of the fragment. The process takes many hours of repetitive labor that could potentially be automated. PROJECT DESCRIPTION The Army is looking for a device or method for quickly producing the required output data. The top surface of the sheet will not be completely smooth, as fragments and spalling will interrupt the flat surface. The fragments may be highly irregular (non-spherical), and they may or may not be securely embedded. Some may be loose and can fall out easily. There may be as many as 96 sheets in a bundle, and at any one time only 3 can be lifted together. Data derived from the analysis of the fragments should be in a spreadsheet format, with the fragment designation, count, sheet number, location, and size/weight. Fragments are typically steel, but some tests use titanium or aluminum. It would be beneficial to be able to locate and identify these metals as well. The desired threshold parameters are described below. 2/6/2016 z THRESHOLD PARAMETERS -X/Y resolution of .5” -Minimum fragment weight of .25g -Maximum time per person per sheet of 15min. PRODUCT PARAMETERS The scanner can be developed as a purely hardware solution or hardware/software solution. Fragment testing is performed in remote areas in the firing range for personnel safety. So, mobility is required for the scanning system. The system must be hosted on a portable device (tablet, laptop, etc.). Windows and Android operating systems are allowable for software development. No Apple operating systems or products are allowed. No Bluetooth connectivity is allowed. WiFi can be used, but fragmentation tests are normally performed in areas of weak reception, or areas with blackout restrictions on transmissions. USB thumb drives are not permitted per US Army security regulations. Data can be migrated between the system and any US Army data networks for additional analysis. Acceptable data migration techniques are: optical storage (CD, DVD, etc.), SATA, e-SATA, or Firewire. USB external drives can be used to backup data only. DELIVERABLES Prototype Fragment Scanning System Full Instruction Manual Quick-Start Guide AVAILABLE RESOURCES Bundle Samples Fragment Samples Professional Machine Shop Facilities 2/6/2016 z PROJECT SPONSOR CONTACT INFORMATION Patrick G. Taylor, Ph.D. Electrical Engineer Director – WDI Electric Propulsion Laboratory Propulsion Technology Function U.S. Army Research, Development, and Engineering Command Aviation and Missile Research, Development and Engineering Center RDMR-WDP-P Bldg. 7120, Redstone Road Redstone Arsenal, AL 35898 Office: 256-842-3031 Mobile: 256-698-4519 Fax: 256-876-9443 E-mail: patrick.g.taylor@us.army.mil 2/6/2016