Lab for Evaluation

advertisement

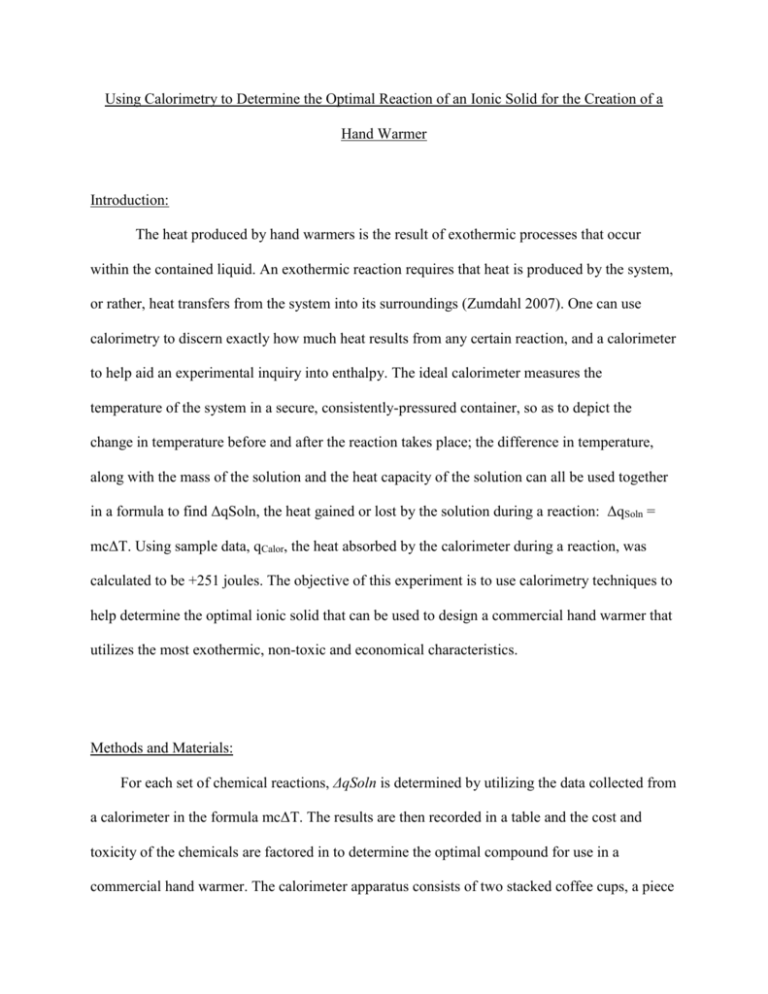

Using Calorimetry to Determine the Optimal Reaction of an Ionic Solid for the Creation of a Hand Warmer Introduction: The heat produced by hand warmers is the result of exothermic processes that occur within the contained liquid. An exothermic reaction requires that heat is produced by the system, or rather, heat transfers from the system into its surroundings (Zumdahl 2007). One can use calorimetry to discern exactly how much heat results from any certain reaction, and a calorimeter to help aid an experimental inquiry into enthalpy. The ideal calorimeter measures the temperature of the system in a secure, consistently-pressured container, so as to depict the change in temperature before and after the reaction takes place; the difference in temperature, along with the mass of the solution and the heat capacity of the solution can all be used together in a formula to find ΔqSoln, the heat gained or lost by the solution during a reaction: ΔqSoln = mcΔT. Using sample data, qCalor, the heat absorbed by the calorimeter during a reaction, was calculated to be +251 joules. The objective of this experiment is to use calorimetry techniques to help determine the optimal ionic solid that can be used to design a commercial hand warmer that utilizes the most exothermic, non-toxic and economical characteristics. Methods and Materials: For each set of chemical reactions, ΔqSoln is determined by utilizing the data collected from a calorimeter in the formula mcΔT. The results are then recorded in a table and the cost and toxicity of the chemicals are factored in to determine the optimal compound for use in a commercial hand warmer. The calorimeter apparatus consists of two stacked coffee cups, a piece of cardboard with a small and large hole, a Vernier LabQuest attached to a temperature probe, a test tube clamp, a funnel, and a stirring plate. The coffee cups are placed on the stirring plate and the magnet is placed inside of the stacked cup, preferably aligned in a fashion that prevents the spin of the magnet being disturbed by the edges of the stacked cup. Then, the cardboard is placed over the opening of the stacked cup; the small hole will house the temperature probe, making sure that it is held securely in place by the test tube clamp, that the end of the probe does not touch the bottom of the cup or the magnet, and that it is fairly centered. The funnel will be put into the large hole (Figure 1). A 100 mL graduated cylinder is also needed to measure 45 mL of the deionized water for each solution as well as an electronic scale to measure 5 g of each ionic solid. The lid is taken off of the calorimeter in order to insert the water. The lid will be replaced and the 5 g of ionic solid will be placed in the calorimeter via the funnel. At this time, the stirring plate will be on and the magnetic pellet will be spinning at a constant speed rate of 4. The initial and peak temperatures will be measured on the LabQuest, allowing about a minute of two for each reaction to complete, and will be recorded. After each reaction is complete, the funnel is cleaned, the solution is dumped, and 45 mL of clean water is put back into the calorimeter. After the temperatures are recorded using the aforementioned equations, Δq will be determined. Using that, as well as the cost and toxicity of each ionic solid, a decision will be made on what substance to use and how the hand warmer will be constructed. Figure 1. General schematics of the calorimeter apparatus. Results: After testing all six ionic solids, it could be assumed from the pre-reaction and postreaction temperatures that calcium chloride, sodium acetate, sodium carbonate and lithium chloride were the only chemicals that had caused an exothermic reaction when mixed with the water; although, upon the calculation of ΔqSoln for each reaction, in which the qCalor was taken into account, sodium chloride was found to be slightly exothermic as well, but not notably so (Table 1). Upon research on Flinn Scientific’s website, it was found that of the four considerably exothermic ionic solids, lithium chloride is not only the second most expensive, but the most toxic, while the other three have both preferable and unpreferable traits (Table 2). Table 1. The data recorded after placing all six ionic solids into the calorimeter. Ionic Solid Pre-Reaction Temperature Post-Reaction Temperature ΔqSoln (kJ/mol) Ammonium Nitrate 20.4 15.3 -.815 Calcium Chloride 23.6 36.8 3.01 Sodium Acetate 23.8 27.4 1.00 Sodium Carbonate 23.1 28.6 1.40 Sodium Chloride 23.0 22.0 .042 Lithium Chloride 23.2 38.8 3.51 Table 2. The toxicity and cost of each of the six ionic solids used in the experiment (Flinn Scientific Inc. 2014). Ionic Solid LD50 Cost (dollars per gram) Ammonium Nitrate 2217 mg/kg .0185 Calcium Chloride 1000 mg/kg .0109 Sodium Acetate 3530 mg/kg .0695 Sodium Carbonate 4090 mg/kg .0129 Sodium Chloride 3000 mg/kg .0083 Lithium Chloride 526 mg/kg .0684 Discussion: The purpose of this study was to determine the best ionic solid to use in a commercial hand warmer through calorimetry techniques based on whether the solid caused an exothermic reaction, the toxicity of the solid, and the price of the solid. After each reaction was completed, it was observed that calcium chloride, sodium acetate, and sodium carbonate generated exothermic reactions in water because of the increase in temperature from pre-reaction to post-reaction. Furthermore, after researching the cost and toxicity of each substance, it was decided that sodium acetate would be used in creating the hand warmer. Sodium acetate generated an exothermic reaction in water, and although it was not the least expensive option, it was the second least toxic ionic substance, making it an optimal choice for placement in a commercial hand warmer. When calculating ΔqSoln, (50 mL) (4.18 J/g·°C) (27.4-23.8) + .251 was plugged in for sodium acetate, the addition of .251 taking into account the heat absorbed by the calorimeter itself. When compared to another high school’s group, it was observed that the group chose lithium chloride rather than sodium acetate; however, this difference most likely stems from the fact that the group did not factor in cost or toxicity into their decision (Santana et al. 2014). However, it is worth noting that while performing the reaction for lithium chloride, the lid to the calorimeter was briefly touched by a Colonia High School lab member, thus leaving a small margin for error when calculating ΔqSoln. In terms of the construction of the hand warmer, it was decided that the device would consist of a cloth pouch containing a thin plastic interior. Inside the pouch would be water, as well as a capsule containing sodium acetate. Thus, upon obtaining the hand warmer, the consumer would only need to squeeze on the pouch in order to snap the capsule open and release the sodium acetate- effectively generating an exothermic reaction that would warm their hands. In terms of the lab’s objective, it was fulfilled using calorimetry techniques to decide upon sodium acetate as the optimal ionic solid, but if interested in further study, one may find interesting results by performing a similar experiment while also attempting to determine how such a hand warmer could be constructed to be reusable. \ Works Cited Danch, James. “Class Discussion.” AP Chemistry Class. Colonia High School, Colonia. 10 September. 2014. Lecture. Danch, James. “Stoichiometry Lab Handout.” AP Chemistry Class. Colonia High School, Colonia. 10 September 2014. Print. Flinn Scientific, Inc. "Chemicals." Flinn Scientific, Inc. Flinn Scientific, Inc., 2014. Web. 13 Oct. 2014. Flinn Scientific, Inc. "Store." Flinn Scientific, Inc. Flinn Scientific, Inc., 2014. Web. 15 Oct. 2014. Santana, Jason. Kozak, Chris. "The Hand Warmer Design Challenge." Prezi Presentation. 28 October. 2014. Web. <http://prezi.com/q4ki1aqvrbf0/the-hand-warmer-design-challenge/>. Zumdahl, Steven S., and Susan A. Zumdahl. Chemistry. 7th ed. Boston: Houghton Mifflin, 2007. Print.