Conditions for Connection to the Transmission System

advertisement

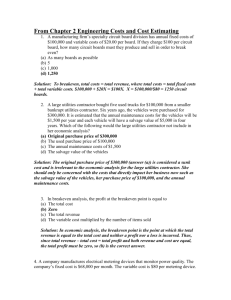

Conditions of Connection to the NET4GAS, s.r.o. Transmission System issued pursuant to Act 458/2000 Coll., on the conditions of business and the execution of the state administration in the energy sectors and on the amendment to certain acts, as amended by later regulations (hereinafter referred to also as the “Energy Act”) and related implementing legal regulations. SECTION I. Basic provisions 1. Gas production facilities, underground gas storage, distribution system, or an end customer may be connected to the NET4GAS, s.r.o. (hereinafter referred to only as N4G) transmission system. A connection to the transmission system shall take place based on a concluded Contract on Connection to the Transmission System. A Contract on Connection to the Transmission System shall contain a) the technical details of the specific technological equipment of the transfer point in accordance with the principles specified in section IV of these connection conditions, b) the method of connecting the connection equipment to the transmission system, c) the conditions of the operation of the connection equipment, d) the method of financing, unless otherwise specified in these connection conditions, e) the dates of the construction of the connection equipment. A Contract on Connection to the Transmission System may be concluded with an applicant in accordance with paragraph 4 of this section after the delivery of an application meeting the requirements specified in paragraph 3 of this section. 2. The applicant is a legal entity or an individual operating gas a production facility, underground gas storage or distribution system as well as an individual or legal entity purchasing gas for its own consumption. 3. The application for connection to the transmission system (hereinafter referred to only as the “application“) shall be drawn up in writing on the application form specified by the transmission system operator, which forms an appendix to these connection conditions. The applicant shall deliver the application for connection to the transmission system operator no later than by the start of the zoning procedure for the connection equipment. In the application the applicant shall specify: a) necessary identification data of the applicant, b) identification data of the future operator of the connection equipment, c) a diagram of the connection equipment, including the suggested connection point, with a scale of 1:5000, d) information regarding the course of the transmission of gas and the required connection conditions, e) the foreseen dates of the construction of the connection equipment and the start of its operation. 4. After the application has been delivered meeting the requirements specified in the preceding paragraph, the transmission system operator shall assess the application in accordance with these conditions and issue a written statement of position to the application at the latest within sixty days of the delivery of the application, in which, if the conditions of connection are met, the operator will give its consent to the connection to the transmission system. Should the transmission system operator discover a discord between the information contained in the application and these connection conditions, the operator shall issue a written statement of position within the deadline specified in the preceding sentence, in which it shall reject the connection to the transmission system and specify the reasons for this rejection. Should the application fail to contain certain appurtenances or should it contain information contradicting the actual situation, the transmission system operator shall return such application to the applicant requesting him to correct such deficiencies without unnecessary delay. The day on which the application shall be deemed delivered shall be the day on which the application is delivered without any deficiencies as specified in the preceding sentence of this provision. 5. The conditions of connection of a gas production facility or an underground gas storage, distribution system or an end customer to the transmission system are specified in sections II and III of these connection conditions. 3 6. The following reference conditions shall be used for the determination of the volume of gas in m , 3 3 gross calorific value in kWh/m , and the Wobbe index in kWh/m : a) temperature 15°C, b) pressure 101.325 kPa (absolute pressure), c) relative gas humidity φ = 0. SECTION II. Joint basic conditions of connection to the transmission system 1. The conditions of a connection of a gas production facility, underground gas storage, a distribution system or an end customer to the transmission system are the following: a) Available capacity of the transmission system at the connection point, which is defined as the difference between the technical capacity of the transmission system at the connection point and the sum of all capacities contractually secured for individual customers in the given period of time while complying with contractual pressures under the conditions of the operation of the transmission system. The scope and timing of gas off-take through the connection equipment must be feasible both technically as well as in terms of dispatching. b) Technical feasibility of the connection, which is determined by the operating conditions in the appropriate part of the transmission system, the requisite reliability of gas transmission with respect to the realistic possibility of gas off-take at the given site, and the fulfillment of the requirements stipulated for the connection equipment under sections IV and V hereto. The connection shall be made under the terms of a Contract on Connection to the Transmission System, after an agreement is reached, at the place specified by the transmission system operator taking into account the applicant’s suggested connection point. The technical feasibility of connection also requires that the following conditions: Specification of a place for the monitoring of the quality of gas enabling the conversion of the gas transferred and taken to energy units. The quantity and quality of gas shall be always metered at border transfer stations and at the exit points of gas production facilities or underground gas storage facilities. In the Contract on Connection to the Transmission System the contracting parties shall agree whether the quality of the gas will be monitored in the new connection (transfer point) or whether a new point for the monitoring the quality of gas will be established, or an already existing point will be used. The point for the monitoring of the quality of gas shall be fitted with equipment pursuant to Public Notice No. 251/2001 Coll., as amended by later regulations. The quantity of gas taken shall be within the range of measurability in line with the verification of the meter in an accredited testing laboratory. The annual utilization of the installed capacity of the equipment shall be at least 2000 hours. c) Compliance with the connection equipment safety and reliability requirements stipulated by legal and technical regulations. d) Compliance with the transfer pressure, which is understood as the compliance with the minimum and if applicable also the maximum transfer pressure at the connection point. 2. The transmission system operator shall verify whether the conditions specified in paragraph 1 of this section have been satisfied within the assessment of the application, and the compliance with these conditions shall become a part of the Contract on Connection to the Transmission System. SECTION III. Specific conditions of connection to the transmission system 1. Conditions of connection of a distribution system N4G shall construct a gas pipeline to the relevant TRS (section IV, type A, type B) pursuant to the public notice on connection to the transmission system with the separating point in front of the main shut-off valve. 1.1. Besides the joint basic conditions of connection specified in section II of these connection conditions, in order to connect a distribution system the scope and the timing of the gas transmission or supply shall be observed accounting for the the the required off-take at the connection point, required capacity at the connection point and requirement of gas transmission reliability. The transmission system operator shall verify whether these conditions have been satisfied within the assessment of the application and the compliance with these conditions shall become a part of the Contract on Connection to the Transmission System. 2. Conditions of connection of gas production facilities or underground gas storage 2.1 Besides the joint basic conditions of connection specified in section II of these connection conditions, the following conditions shall apply to the connection of a gas production facility or underground gas storage: a) compliance with the required quality of gas, b) compliance with the scope and timing of the gas transmission or supply of gas accounting for: the required off-take of gas from the transmission system or supply of gas to the transmission system at the connection point, the transmission capacity at the connection point, and requirement of gas transmission reliability. The transmission system operator shall verify whether these conditions have been satisfied within the assessment of the application and the compliance with these conditions shall become a part of the Contract on Connection to the Transmission System. 2.2 The required quality of gas specified 2.1 a) of this section in the case when gas is delivered to the transmission system from an underground gas storage, to which it has been previously stored from the transmission system, shall be deemed such quality of gas corresponding to its quality when it was delivered for storage, as regards the following properties: gas purity (content of solid and liquid impurities), chemical composition (the chemical composition gross calorific value, water dew point, hydrocarbon dew point. shall not be substantially altered), In the case when gas is transferred to the transmission system from a gas production facility or underground gas storage the transferred gas shall be deemed to meet the required quality specified in point 2.1 a) of this section if it complies with the requirements specified in appendix 2 of the transmission system operator’s Network Code, unless otherwise agreed by the transmission system operator and the applicant. 3. Conditions of connection of an end customer N4G shall construct a gas transfer station (section IV, type C) pursuant to the public notice on connection to the transmission system with the separating point in front of the main shut-off valve. 3.1. Besides the joint basic conditions of connection specified in section II of these connection conditions, the following conditions shall apply to the connection of an end customer: a) in the case of a connection to the transit system pipelines of the transmission system the energy value of the annual quantity of gas taken shall be at least 100 000 MWh/year; b) in the case of a connection to other N4G VHP and HP gas pipelines of the transmission system the energy value of the annual quantity of gas taken shall be at least 10 000 MWh/year; c) agreement on the off-take diagram of the gas supply taking into account the reliability of supply; d) there is no distribution system pipeline with sufficient available capacity within reach at the time when the application for connection is filed. The transmission system operator shall verify whether these conditions have been satisfied within the assessment of the application and the compliance with these conditions shall become a part of the Contract on Connection to the Transmission System. 3.2. In the case of an application for connection of an end customer which does not satisfy the requirements of a), b) and/or d) of article 3.1, the technical and economic feasibility of the connection will be taken into account within the assessment of the application. 3.3. A contract on the method of financing of the construction of the connection equipment shall be concluded with the transmission system operator in order to connect the end customer to the transmission system. The end customer shall deliver a draft contract under this provision to the transmission system operator no later than on the penultimate day of the period specified in paragraph 4, section I, of these connection conditions. The period specified in paragraph 4, section I, of these connection conditions shall be suspended from the submission of the draft contract according to these provisions until the said contract is concluded. SECTION IV. Basic technical types of gas transfer and regulating stations (TRS) and transfer stations (TS) for the construction and reconstruction of very high-pressure and high- pressure facilities 1. VHP a HP gas transfer and regulating stations that are being connected to the transmission system shall be constructed or reconstructed in accordance with the following types: 1.1 TYPE A 1.1.1 Gas regulating and transfer stations with technological equipment assembled as a whole consisting usually of the following: filters, if the connected technology requires such filtering, gas pre-heating, gas pressure regulator, pressure relief and safety quick-closing valve, HP (MP) custody transfer metering technology including HP (MP) custody transfer meter with flow computers, gas flow limiter (if required), data logger recording the pressure at the transfer point, i.e., in front of the main shutoff valve, station control system and connection to N4G dispatching center and the customer’s dispatching center, the related pipe sections (pipes, fittings, valves, etc.) as specified in section V. 1.1.2 The technological equipment is located in a single building. These are usually kiosktype stations designed for small volumes with custody transfer metering at the exit side. 1.2 TYPE B 1.2.1 The transfer and regulating station is again situated in a single building just like in the case of type A, whereas the technological equipment usually consists of: a) separate transfer station technology including filters, if the connected technology requires such filtering, VHP custody transfer meters with flow computers, gas flow limiters, related pipe sections (pipes, fittings, valves, etc.), data logger recording the pressure at the transfer point, i.e., in front of the main shutoff valve, transfer station control system and connection to N4G dispatching center and the customer’s dispatching center, the related pipe sections (pipes, fittings, valves, etc.) as specified in section V, connection to N4G dispatching center. b) separate gas pressure regulation and gas odorizing including: filters, if the filtering is not a part of the custody transfer metering technology and the connected technology requires such filtering, gas pre-heating, gas pressure regulation, pressure relief quick-closing valves, control system of pressure regulation, odorizing and common equipment, connection to the customer’s dispatching center, gas odorizing, related pipe sections (pipes, fittings, valves, etc.). 1.2.2 The technological equipment is again located in a single building along with the boiler room, the backup power supply source, and the electricity substation, whereas the technological parts a) and b) are separated from each other and accessible through separate entrances. 1.3 TYPE C 1.3.1 VHP gas transfer stations with VHP custody transfer metering equipment: filters, if the connected technology requires such filtering, VHP custody transfer meters with flow computers, gas flow limiters, related pipe sections (pipes, fittings, valves, etc.), transfer station control system, data logger recording the pressure at the transfer point, i.e., in front of the main shutoff valve connection to N4G dispatching center. 1.3.2 The VHP transfer station technological equipment is located in a separate building. 1.3.3 Gas pressure regulation shall takes in a separate building which may be located at any distance from the transfer station. 2. The requirements for other equipment of transfer stations enabling the monitoring of the gas quality shall be specified in the Contract on Connection and detailed in the comments to the design documentation. 3. The equipment operated by N4G shall be situated separately from the rest of the technological equipment (in line with section V) and selected N4G workers shall have unrestricted access to the equipment. 4. The distance of TS and TRS from N4G pipelines, to which they are being connected, shall be defined in the project design. 5. Any contingent deviations from the principles specified in this section shall be agreed in the Contract on Connection. SECTION V. Technical terms and property right relations at gas VHP and HP transfer and regulating station (TRS) and transfer station (TS) equipment and their connection to the transmission system pipelines 1. General principles applicable to the entities that are being connected. 1.1. Connecting pipeline The pipeline shall be constructed in line with all valid standards and regulations. 1.1.1.N4G shall cautiously select the pipeline route based on the ordered feasibility study. 1.1.2.N4G workers shall have access to the N4G technology on the plots owned by the connected entity. 1.1.3.The pipeline shall comply with ČSN EN 1594 (38 6410) and TPG 702 04. A closing valve shall be installed at the connection point satisfying together with the control actuator the conditions of installation on a pipeline with cathodic protection. 1.1.4.The pipeline shall be owned and operated from the connection point to the separating point by N4G. The connected entity shall own and operate the gas service line. 1.1.5.The minimum size of the pipeline is DN80, it shall be made of steel. The pipeline shall be protected by outer coating as well as cathodic protection along its entire length. 1.1.6.The separating point shall be precisely specified in the Contract on Connection. 1.1.7.TRS and TS shall be galvanically separated from the entry and exit pipelines using insulating couplers. 1.2. Control system and telemetry 1.2.1.The control system of the whole TS shall be owned by N4G. This includes transducers, cables, PLC, modems, fiber-optic cable, routers. 1.2.2.N4G workers shall have access to the technology on the plots owned by the connected entity. 1.2.3.Data shall be transferred to the N4G dispatching center (hereinafter referred to only as DN4G) through the IEC 60870-5-104 protocol. N4G shall build the connection and the connection type shall always depend on the particular site (fiber-optic connection with WAN N4G, GPRS/EDGE router etc.) Selected data from TS defined in the interconnection agreement may be provided to the connected entity through: a) On-line connection of the connected entity’s PLC and N4G PLC if the connected entity needs this data in order to control its technology (e.g., shutdowns, blockades, odorizing control etc.) using the Modbus RTU protocol, in which case N4G shall always be the Master. The selection of the serial interface type (RS485/RS232/RS422) is up to an agreement between N4G and the connected entity and the length of the connection. b) i. ii. iii. Off-line periodically using files in the defined format (txt, csv, xls, xml) through FTP E-mail Edig@s c) On-line protocol TASE.2 pursuant to IEC 60870-6 using Conformance block 1 and Conformance block 2. Cases b. and c. refer to the transfer of data from the N4G control system. The selection of the data transfer method is up to an agreement of the parties. 1.2.4.The control system for RS shall be owned by the connected entity. The connected customer shall use only the data acquired from his own metering for the regulation as such. 1.2.5.The contingent interconnection of both systems at the local level shall be detailed in the Contract on Connection. 1.2.6.Electromagnetic compatibility (EMC) shall be secured for all electrical and electronic components of the control system in line with the valid standards and regulations 1. 1.2.7.Depending on the particular technical solution, the Contract on Connection shall specify the equipment owned by the connected entity and in particular the states of the equipment transferred to the N4G dispatching center. 1 EN 61000-4-2, EN 6100-4-3 (CISPR 11), EN 61000-4-4, EN 61000-4-5, EN 6100-4-6, EN 61000-4-8, EN 61000-4-11, EN 61000-4-12 1.3. Custody transfer metering The selection of the metering equipment is subject to the applicable public notices 2, technical standards3 and N4G internal guidelines, Custody transfer metering is used for the determination of the quantity of energy transferred between N4G and the connected entity. There shall be no unmetered gas under any circumstances passing through TRS regardless of whether intentionally or unintentionally. The expert guarantor of the system – N4G senior manager for custody transfer metering – shall select the metering equipment assessing it as regards the calibration periods, linkage to the state reference standards, competence of external suppliers etc. according to the particular requirements for the gas custody transfer metering. The technical solution of the metering equipment shall be designed and selected to cover the minimum as well as the maximum gas flows specified in the application for connection to the transmission system and to comply with the admissible metering equipment tolerances and also to eliminate negative effects as much as possible (pulsing, vibrations etc.). The metering equipment shall be verified in line with the legal requirements. N4G workers shall have access to the technology on the plots owned by the connected entity. The N4G senior manager for custody transfer metering shall define the configuration of the individual elements of custody transfer metering in line with the valid legislation. All custody transfer metering equipment shall be owned by N4G. In particular, this concerns the flow meters, flow computers, UPS, switchboards, cables, devices connected with the chromatograph etc. Custody transfer metering specifies requirements for data transfer to the fiscal network. 1.4. Filtering A gas transfer or off-take point shall be fitted with equipment for the separation of solid and if applicable also liquid impurities contained in natural gas in line with TPG 959 01, TPG 605 02, ČSN EN 1776. Unless otherwise agreed in the Contract on Connection, the filtering technology shall be owned by N4G. 1.5. Odorizing Gas taken from the NET4GAS transmission system is not odorized. 1.6. Operating costs, electricity The costs of operation of the relevant technology shall be born by its owner. A closer specification, which shall be stipulated in the Contract on Connection, depends on the particular technical solution. 2 Public notice no. 251/2001 Coll. ČSN EN 1776, defining the functional requirements for the design, construction, commissioning, operation and maintenance of new metering stations with the operating pressure of at least 1 bar (relative pressure) designed for custody transfer metering of natural gas. 3 List of abbreviations used: N4G NET4GAS, s.r.o. TS transfer station TRS transfer and regulating station VHP very high-pressure pipelines (pressure range 4.0 – 10.0 MPa) HP high-pressure pipelines (pressure range 0.4 – 4.0 MPa) MP medium-pressure pipelines (pressure range 50 - 400 kPa) m3 cubic meter of gas at the temperature of 15°C and pressure of 101.325 kPa (absolute pressure). Terminology: Transit system part of the transmission system designated for transit transmission over the territory of the Czech Republic to foreign countries and gas transmission for supply to the Czech Republic. Other N4G VHP and HP pipelines part of the transmission system designated only for gas transmission for supply to the Czech Republic. Pressure is understood in these conditions as relative pressure, unless explicitly specified otherwise. References to standards and regulations: ČSN EN 1594 (38 6410) Gas supply systems. Pipelines with maximum operating pressure over 16 bar. Functional requirements. ČSN EN 12 186 (38 6417) Gas supply systems. Gas pressure regulating stations for transmission and distribution. Functional requirements. TPG 702 04 GAS technical rules “Gas mains and service lines made of steel with maximum operating pressure up to and inclusive of 100 bar“. TPG 605 02 GAS technical rules “Gas pressure regulating stations“. Appendices: Application for Connection to the Transmission System