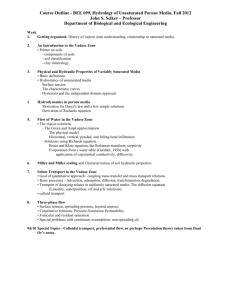

CHAPTER 7 - Clemson University

advertisement

Intro to Chapter 7 Vadose Zone, Science and Technology Solutions Battelle Press CHAPTER 7 REMEDIATION OF ORGANIC CHEMICALS IN THE VADOSE ZONE by Lawrence C. Murdoch 7.1 INTRODUCTION The remediation of organic chemicals in the vadose zone has been blessed by remarkable success, but it has also been cursed by challenges to even our most advanced capabilities. This spectrum of outcomes to the remedial process is a result of the diversity of conditions encountered at contaminated sites. Organic chemicals are rarely stored or intentionally placed beneath the water table, so the source of most organic contaminants is at the ground surface or in the shallow vadose zone. As a result, nearly all sites containing organic contaminants have at least some problems in the vadose zone, and commonly the greatest concentrations of contaminants occur in the vadose zone near the source. The large number of sites requiring vadose zone remediation presents a broad range of conditions and circumstances, including factors related to geologic conditions, properties of the contaminants, and the ability to access the subsurface. All are critical to the performance of the remedial technique, and currently no single technique addresses all the factors found at contaminated sites. Instead, an array of techniques has been developed, some to target widespread problems and others to address the more difficult niches. The development of soil vapor extraction (SVE) in the mid to late 1980s provided a method that significantly reduces the mass of volatile compounds at sites underlain by relatively dry, sandy sediments, in areas readily accessed by conventional drilling. A significant number of sites meet those criteria, and SVE has been used to close many of them. SVE is widely available and, along with several companion techniques, it forms the backbone of our organic chemical remediation capabilities. A variety of conditions impede SVE performance. Organic contaminants may partition into the vapor phase only sparingly, or the underlying material may be tight or marked by significant heterogeneities, or the contaminated region may be beyond the influence of conventional wells. These factors reduce the effectiveness of SVE, delaying the completion of remediation and increasing costs. Performance improvement and cost reduction motivated the development of at least a dozen other technologies for remediating organic chemicals in the vadose zone. Each of Intro to Chapter 7 Vadose Zone, Science and Technology Solutions Battelle Press the innovative technologies either stretches the limitations caused by geology, contaminant properties, or access, or reduces the equipment and operating costs of conventional SVE. Some are designed to improve SVE performance itself, for example, by heating the ground to accelerate the contaminant evaporation and increase the recovery rate. Others draw on different physical or chemical processes for remediation. Contaminant recovery is by no means the only remediation method for the vadose zone. Bioremediation of hydrocarbons has been widespread and successful in many vadose settings. Other possibilities include chemically altering contaminants to benign compounds, or injecting chemicals to markedly reduce the mobility of contaminants and limit their ability to migrate to potential receptors. At some sites, naturally occurring processes may reduce the concentrations of contaminants so that subsurface monitoring is sufficient to ensure remediation. The purpose of this chapter is to identify the current state of our capability to remediate organic chemicals in the vadose zone. This is accomplished by first describing the remedial technologies that are currently available. The second part of the chapter is a comparison of the performance of these technologies under a variety of conditions at contaminated sites. Most of the remediation methods considered here fall unambiguously into one of four major classes of remedial methods: recovery, destruction, immobilization, and natural processes, and the chapter is organized around these classes. However, a few of the technologies are capable of more than one type of action; for example, heating the subsurface will improve recovery but it can also destroy some contaminants by oxidization or pyrolysis. All of the technologies described in the following pages have advanced through the development process and are now offered as a service by private companies. Some are widely available, while other methods are more specialized and available from one, or perhaps only a few, companies. A variety of other methods currently show promise in the laboratory, and it is expected that they will soon be added to the list of commercially available techniques. However, only methods that are commercially available at this time are described in this chapter. 7.1.1 Contributors To The Chapter Methods for remediating organic chemicals in the vadose zone have evolved rapidly over the past few years, and important advances in technologies have often outpaced descriptions in technical journals. In order to document the current status of each technology, we have obtained contributions from leading experts who are aware of the most recent activities and developments. Contributors to this chapter and the technologies they describe are cited below. Recovery Technologies SVE; John S. Gierke Intro to Chapter 7 Vadose Zone, Science and Technology Solutions Battelle Press Department of Geological Engineering and Sciences Michigan Technological University 1400 Townsend Drive Houghton, MI Passive SVE; Joseph Rossabi Westinghose Savannah River Company Bldg 773-42A, Rm 249 Aiken, SC 29808 SVE with heating Thermal Conduction; John Reed, Denis Conley, TerraTherm 10077 Grogans’s Mill Road The Woodlands, TX 77380 Radio-Frequency Heating; James Phelan PO Box 5800 MS 0719 Sandia National Lab Albequerque, NM 87185 jmphela@sandia.gov Steam flooding; Ronald W. Falta, Department of Geological Sciences Clemson University Clemson, SC 29634 Email: faltar@clemson.edu Electrical resistance heating; William Heath, Pacific Northwest National Lab Hanford, WA Destruction Technologies Bioremediation; Terry Hazen, Earth Sciences Division Lawrence Berkeley National Laboratory Intro to Chapter 7 Vadose Zone, Science and Technology Solutions Battelle Press MS 90-1116 1 Cyclotron Road Berkeley, CA 94720 Email: tchazen@lbl.gov Phone: 510-486-6223 Injected oxidants; Robert L. Siegrist, Michael A. Urynowicz Colorado School of Mines Environmental Science & Engineering Division 112 Coolbaugh Hall Golden, CO 80401-1887 USA Email. rsiegris@mines.edu Olivia R. West Oak Ridge National Laboratory Environmental Sciences Division 1505 Bethel Valley Road Oak Ridge, TN 37831-6036 Email. qm5@ornl.gov Lance permeation; Robert L. Siegrist, Colorado School of Mines Environmental Science & Engineering Division 112 Coolbaugh Hall Golden, CO 80401-1887 USA Email. rsiegris@mines.edu Gas-phase oxidants; Wilson Clayton, IT Corporation 5600 S. Quebec St., Suite 200B Englewood, CO 80111 wclayton@theITGroup.com Reactive barriers; Lawrence C. Murdoch, Department of Geological Sciences Intro to Chapter 7 Vadose Zone, Science and Technology Solutions Battelle Press Clemson University Clemson, SC 29634 and FRx Inc, Email: lmurdoch@clemson.edu William W. Slack FRx, Inc. P.O. Box 8292 Cincinnati, OH 45249-8292 e-mail: wslack@frx-inc.com Deep Soil Mixing; Robert L. Siegrist Colorado School of Mines Environmental Science & Engineering Division 112 Coolbaugh Hall Golden, CO 80401-1887 USA Email. rsiegris@mines.edu Olivia R. West Oak Ridge National Laboratory Environmental Sciences Division 1505 Bethel Valley Road Oak Ridge, TN 37831-6036 Email. qm5@ornl.gov Immobilization Technologies Solidification and Stabilization; Paul Bishop, University of Cincinnati Cincinnati, OH 45221 Paul.Bishop@uc.edu Vikram Hebatpuria Malcolm Pirnie, Inc., Mahwah, NJ 07495-0018 Natural Processes Phytoremediation; Larry E. Erickson, L. C. Davis, and P. A. Kulakow Kansas State University Intro to Chapter 7 Vadose Zone, Science and Technology Solutions Battelle Press Manhattan, KS 66506 lerick@ksu.edu