Calibration Method for Soil Respiration Systems

advertisement

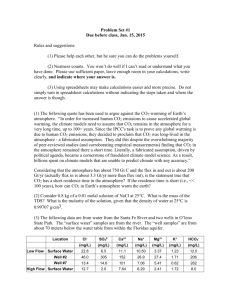

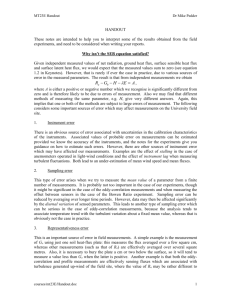

02/06/16 Martin et al. Do not duplicate or distribute -1- 1 2 3 4 5 A Calibration Method for Infrared Gas Analyzer (IRGA) - Based Soil 6 Respiration Systems: An Artificial Flux Generator. 7 8 Jonathan G. Martin1,3, Paul V. Bolstad1, and John M. Norman2 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 Submitted to Global Change Biology as a note. 1 Department of Forest Resources, University of Minnesota. , 115 Green Hall, 1530 Cleveland Av. N., St. Paul, MN 55108 USA. 2 Department of Soil Science, University of Wisconsin-Madison, 1525 Observatory Dr, Madison, WI 53706 USA 3 Author to whom all correspondence should be addressed. jmartin@foresty.umn.edu 02/06/16 Martin et al. Do not duplicate or distribute -2- 1 2 Abstract An artificial flux generation system was developed to test the accuracy of a soil 3 respiration system. The device consisted of an enclosed reservoir with a porous top and 4 an Infrared Gas Analyzer (IRGA) that records the internal CO2 concentration of the 5 reservoir. When the internal CO2 concentration within the reservoir is elevated, diffusion 6 rates through the porous medium can be measured. This diffusion mimics natural soil 7 respiration and can allow an independent verification of the accuracy of soil respiration 8 measurement systems. By placing the soil respiration system to be tested on top of the 9 porous layer of the flux generation system, deviations from a 1:1 relationship can be 10 measured. A LI-COR 6400 portable photosynthesis system fitted with a 6400-09 soil CO2 11 flux chamber overestimated the generated flux rates by 3-4% when tested over five 12 independent trials. 13 02/06/16 Martin et al. 1 Do not duplicate or distribute -3- Introduction 2 Soil carbon fluxes are of great interest because of their impacts on global carbon 3 budgets and carbon cycling. Approximately 2,100 Gt of carbon are stored in global soils 4 (Bouwman, 1990; Gorham, 1991), and these stores could seep 50-75 Gt of carbon into 5 the atmosphere annually through autotrophic and heterotrophic respiration (Raich and 6 Schlesinger, 1992). Soil carbon cycles are complex and difficult to quantify; however, 7 they are being better understood through advances in monitoring equipment. One such 8 advance has been the portable infrared gas analyzer (IRGA) equipped with a chamber 9 suited to measuring carbon dioxide fluxes at the soil surface. These devices have 10 simplified soil respiration measurements, increased measurement accuracy, and allowed 11 increased spatial and temporal sampling frequency when compared to older methods. 12 However, these IRGA based systems do have their problems. 13 Estimates of CO2 flux from an IRGA are based on a measured increase in CO2 14 concentration within a measurement chamber, which is placed over a fixed area. This 15 change results in CO2 evolution per unit area per unit time, commonly given in mg CO2 16 m-2 hr-1 or mol CO2 m-2 sec-1. Unfortunately, improper use such as poor IRGA 17 calibration, changes in pressure within the measurement chamber (Lund et al., 1999), 18 uneven concentration gradients, and disturbances of the soil medium can affect diffusion 19 and thereby give misleading flux rates. IRGAs may be calibrated with known gasses to 20 ensure that the concentrations measured are reported accurately. Unfortunately, the 21 physics of pressure and concentration gradients that are involved in quantifying a soil 22 CO2 flux make testing soil respiration systems very difficult. While an IRGA may give 02/06/16 Martin et al. Do not duplicate or distribute -4- 1 the correct concentration, these readings may not be translated into a representative 2 surface flux due to misuse or mechanical error. 3 Previous work has compared different measurement systems and techniques in 4 attempts to validate estimates of soil CO2 flux. (de Jong et al., 1979; Norman et al., 5 1997). These comparisons were among measurement methods with unknown “true” 6 values. The accuracy and repeatability of soil flux measurements have not been well 7 documented, yet they should be if soil CO2 flux estimates are to be trusted. This paper 8 describes a testing device that produces a known flux of CO2, which can be used to 9 estimate the accuracy of IRGA-based soil respiration measurements. This calibration 10 11 process should allow field measurements of fluxes to be used more confidently. 02/06/16 Martin et al. Do not duplicate or distribute 1 Materials and Methods 2 Flux Generation System Overview -5- 3 The flux generation system is based on modifications of a design proposed by 4 Nay et al. (1994; see Fig. 1). We constructed a device that works by diffusion and not 5 mass flow. Earlier attempts that involved the active pumping of CO2 may have led to 6 pressure differences and possibly caused underestimations of surface flux. Our flux 7 generation system consisted of a large reservoir filled with carbon dioxide of a known 8 concentration. Elevated CO2 within the reservoir creates a concentration gradient that 9 drives CO2 diffusion through a porous medium at the top of the reservoir. This diffusion 10 rate can then be calculated by measuring the decreasing internal CO2 concentration of the 11 flux generation reservoir (Cireservoir) with an IRGA set in a closed cycle (reference IRGA). 12 CO2 efflux rates at the surface of the diffusion medium follows the equation 13 14 (From LI-COR, 1997): Rs generated Cireservoir Cireservoir W kPV S (Tair 273) t (1000 W ) t 15 16 Where Rsgenerated is generated soil respiration (mol m-2 sec-1), k is a units conversion = 17 10/8.314 = 1.2028, P is pressure (kPa), V is the reservoir volume of the flux generation 18 unit (cm3) including all hoses and the approximate air space in the diffusion layer, S is the 19 area of the diffusion opening (cm2), Cireservoir is the internal CO2 concentrations (mol 20 mol-1), t is the time (sec), and W is the concentration of water vapor (mmol mol-1). 21 The measurement chamber for the soil respiration system to be tested (test IRGA) 22 is placed upon the diffusion medium and is used as it would be in the field . Care must be 23 taken to note the time at which each “test” measurement is recorded so that it can be 02/06/16 Martin et al. Do not duplicate or distribute -6- 1 compared with the calculated fluxes from the flux generation system. If done cautiously, 2 a wide range of generated fluxes can be produced. We were able to produce efflux rates 3 from approximately 11.0mol m-2 sec-1 down to 0.5mol m-2 sec-1. This range of 4 generated rates spans the range reported for soils from various biomes (Winston et al., 5 1997; Davidson et al., 1998). 6 7 System Construction 8 The flux generation reservoir consisted of two, 19-liter cylinders (two 5-US 9 gallon utility buckets) affixed top to top with the upper most bucket having the bottom 10 removed (Fig. 1). A metal screen (5 mm mesh size) was glued to a layer of silk, and then 11 inserted inside the upper bucket approximately 10 cm from top. We placed 4 cm of glass 12 beads approximately 0.65 mm in diameter (Potters Industries Inc., Valley Forge, PA) on 13 top of the screen to act as a constant diffusion medium (Fig. 1a). This layer was carefully 14 leveled to reduce the variation in flux rates across the surface caused by differing 15 diffusion column lengths. We then measured the surface area of the diffusion layer (557.8 16 cm2) and the entire reservoir volume (38,594.1 cm3) including the hoses, reference IRGA 17 volume, and the approximate pore space of the bead layer. 18 Input gas for the reference IRGA was drawn from directly below the glass beads 19 through a series of perforated hoses distributed in a radial pattern (Fig. 1b). This inlet 20 consisted of five perforated hoses with 1/8 inch (0.32 cm) inside diameter (Bev-A-Line 21 IV tubing, Thermoplastic Processes, Millington, NJ). The perforations were spaced 22 approximately 1.5 cm apart and were 1.5 mm in diameter. These hoses were joined to a 23 sixth hose that led to the inlet of the reference IRGA. Exhaust gas from the reference 02/06/16 Martin et al. Do not duplicate or distribute -7- 1 IRGA was fed back into the system at the bottom of the reservoir (Fig. 1c) and was 2 mixed by a slowly turning, 3 inch fan (Fig. 1d). The fan was powered by a variable-speed 3 DC power source (BK Precision, Placentia, CA). A valve was fixed on the chamber so 4 CO2-enriched air could be fed directly into the system prior to measurement (Fig. 1e). 5 The easiest method of introducing CO2 into the system is to simply exhale though the 6 hose until the desired Cireservoir is reached. The valve was closed prior to measurement. 7 A second fan was placed at an angle 20 cm above the bead surface to mix the 8 boundary layer between the beads and the atmosphere (Fig. 1f). This was necessary due 9 to the sensitivity of the generated fluxes to changes in the diffusion gradient. As the CO2 10 concentration within the flux generation reservoir decreased, the ambient CO2 11 concentration at the surface of the beads increased unless the boundary layer was mixed. 12 A build up of CO2 at the surface of the diffusion layer greater than that set inside the test 13 IRGA chamber will result in over-estimations of CO2 flux. This is due to a stronger 14 diffusion gradient inside the test IRGA chamber and a relatively weaker gradient outside. 15 Some soil respiration systems use a specified ambient CO2 concentration within the 16 measurement chamber. This concentration is set close to ambient at the soil surface and 17 then the chamber volume is partially scrubbed of CO2. Measurements are then recorded 18 as concentration within the measurement chamber increases from below ambient to 19 above it. For systems that use a preset ambient CO2 concentration (LI-COR 6400) or 20 where the ambient CO2 concentration is adjusted manually (LI-COR 6200), care must be 21 taken to ensure that the ambient CO2 concentration used in the test chamber is similar to 22 that at the surface of the diffusion layer. 23 02/06/16 Martin et al. 1 Do not duplicate or distribute -8- Leak Test 2 We conducted a simple leak test prior to removing the bottom of the upper bucket 3 for the installation of the diffusion layer. The reference IRGA was attached to the 4 reservoir and the internal CO2 concentration of the flux generation reservoir was 5 increased to roughly 2800 mol mol-1. This closed volume was monitored for 1.3 hours. 6 The Cireservoir dropped 9.6 mol mol-1, which resulted in a flux error of 0.06 mol m-2 7 sec-1 or 0.6% of the corresponding generated flux (with Cireservoir ≈ 2800, Rsgenerated ≈ 10.5 8 mol m-2 sec-1). This was well below the sensitivity of the test IRGA so this error was 9 ignored. 10 11 Diffusion Lag Time 12 After the diffusion layer was installed, we measured the lag time for gas 13 movement across the diffusion medium. The reference IRGA logged Cireservoir every 14 second while the test IRGA, resting on the bead surface, was configured to do the same. 15 Pulses of CO2 were introduced into the reservoir and were observed within seconds in the 16 test IRGA. Thus, a drop in Cireservoir corresponded to a similar diffusion rate at the bead 17 surface, so no time correction for the test IRGA measurements was needed. 18 19 Test Measurements and Flux comparison 20 For the reference IRGA, we used a LI-COR 6400 that had been re-plumbed to 21 form a closed system. The test IRGA was a second LI-COR 6400 fitted with a 6400-09 22 soil CO2 flux chamber. The internal CO2 of the reservoir was elevated to ~3000 mol 23 mol-1, and the reference IRGA was programmed to log Cireservoir every minute. The 02/06/16 Martin et al. Do not duplicate or distribute -9- 1 maximum, accurately detectable concentration listed by the specifications of the LI-COR 2 6400 is ~3000 mol mol-1, so care was taken to ensure Cireservoir remained less than this. 3 The test IRGA was then readied as specified by the LI-COR 6400-09 soil CO2 flux 4 chamber instruction manual and placed on a special 10-cm diameter PVC collar inserted 5 into the diffusion layer. This collar was similar to the ones provided by LI-COR for use 6 in field soil respiration measurements, but was 6 cm tall rather than 4.5 cm to ensure the 7 top was well above the beads of the diffusion layer. Also, holes were drilled in this collar, 8 well below the surface of the beads, to aid in lateral gas movement within the diffusion 9 layer. Test measurements were then taken and the time carefully noted. 10 Once the testing cycle was completed (i.e. the Cireservoir was near the ambient 11 concentration), we used equation 1 to calculate fluxes from the diffusion layer for the one 12 minute increments between consecutive Cireservoir measurements (Fig. 2a). Then, using 13 nonlinear regression (Rsgenerated = a*e(-b*time), JMP 3.2.5), we predicted Rsgenerated for each 14 measurement from the test IRGA. The test and generated fluxes were then compared 15 (Fig. 2b). This cycle of measurements was done five times at different locations on the 16 diffusion surface. The five sets of comparisons were pooled and a t test was used to 17 determine if the slope of the line was significantly different from 1. To help visualize the 18 magnitude of the differences between the predicted and the measured values, we used 19 linear regression (JMP version 3.2.5) to predict the measured test fluxes for each of the 5 20 trials at generated fluxes of 0.5, 2.5, 4.5, 6.5, 8.5, and 10.5 mol m-2 sec-1. 21 02/06/16 Martin et al. 1 Do not duplicate or distribute - 10 - Results and Discussion 2 The slope of the measured values in figure 2b was significantly different than 1 (n 3 = 1157, β1 = 1.0512, p < 0.0001); however, this difference was very small. The trend 4 shows an over-estimation at high rates and an under estimation at low rates. This error is 5 much smaller than the 15% reported by Nay (1994). He reported on a different type of 6 soil respiration system, which could indicate that systems might differ. For the LI-COR 7 6400 used in this study, the generated rates of 0.5, 2.5, 4.5, 6.5, 8.5, and 10.5 mol m-2 8 sec-1 resulted in mean measured respiration rates for the 5 trials of 0.3, 2.5, 4.6, 6.7, 8.8, 9 and 10.9mol m-2 sec-1 respectively. With the exception of the low flux rates (0.5 mol 10 m-2 sec-1), the LI-COR 6400 over-estimated soil surface CO2 flux by 3-4 %. 11 We feel that the small discrepancies between test and reference measurements 12 may stem from a changing boundary layer CO2 concentration. Although the addition of 13 the boundary layer mixing fan helped to alleviate this problem, at high internal reservoir 14 concentrations (e.g. 2000 – 3000 mol mol-1) the ambient set point may have been lower 15 than boundary layer concentration, resulting in a stronger diffusion gradient inside the 16 test chamber. The opposite is true at low Cireservoir (e.g. 600-700 mol mol-1 ) where the 17 ambient set point may be too high. Attempts to increase the mixing of the boundary layer 18 through additional fans created pressure differentials and lead to over-estimations; an 19 effect similar to the concentration differentials. Careful monitoring of the ambient CO2 20 concentration and continually adjusting the ambient set point of the IRGA could possibly 21 reduce these slight measurement errors. 22 We feel that an apparatus like the one describe here could be used to test such 23 problems as differing ambient concentrations, pressure changes and disturbance effects. 02/06/16 Martin et al. Do not duplicate or distribute - 11 - 1 While the current internal concentration (3000 mol mol-1) does mimic some systems 2 (Billings et al., 1998), increasing Ci to 5000 or 10,000 mol mol-1 would more closely 3 resemble a typical soil and would decrease the sensitivity to the ambient concentration 4 gradients. Higher concentrations would create a stronger concentration gradient that 5 would allow smaller beads to be used in the diffusion layer. These smaller beads would 6 better represent typical soil particle sizes. 7 In conclusion, the general trend seen here demonstrates of the accuracy of the LI- 8 COR 6400 soil respiration system. Measurement errors may occur; but with careful 9 calibration, proper use, and independent verification, highly accurate flux measurements 10 may be obtained. A testing system, such as the one described here, may be used to 11 determine the absolute accuracy of IRGA based soil respiration systems, which can then 12 be used to confidently quantify CO2 fluxes from the soil. We feel this apparatus may be a 13 useful tool in calibrating any IRGA based system and for detecting potential sources of 14 measurement error, and should be used as part of a normal maintenance regime. Properly 15 observed measurements are vital for useful models. 16 Acknowledgements 17 This work was supported by the National Institute for Global Environmental 18 Change (NIGEC), Midwest Center, and by the University of Minnesota, Department of 19 Forest Resources. 20 02/06/16 Martin et al. Do not duplicate or distribute - 12 - Literature cited 6400-09 Soil Flux Chamber Instruction Manual (1997) Publication No. 9710-119, LICOR, Inc. Lincoln, NE. Billings SA, Richter DD, Yarie J (1998). Soil carbon dioxide fluxes and profile concentrations in two boreal forests. Canadian Journal of Forest Research, 28, 17731783. Bouwman AF (1990) Exchange of greenhouse gases between terrestrial ecosystems and the atmosphere. In Soils and the Greenhouse Effect, ed. A. F. Bouwman, Wiley, Chichester. 61-127. Davidson EA, Belk B, Boone RD (1998). Soil water content and temperature as independent or confounding factors controlling soil respiration in a temperate mixed hardwood forest. Global Change Biology, 4, 217-227. de Jong E, Redmann RE, Ripley EA (1979) A comparison of methods to measure soil respiration. Soil Science, 127, 300-306. Gorham E (1991) Northern peatlands: Role in the carbon cycle and probable responses to climatic warming. Ecological Applications, 1, 182-195. Lund CP, Riley WJ, Pierce LL, Field CB (1999) The effects of chamber pressurization o soil-surface CO2 flux and the implications for NEE measurements under elevated CO2 Global Change Biology, 5, 269-281. Nay MS, Mattson KG, Borman BT (1994). Biases of chamber methods for measuring soil CO2 efflux demonstrated with a laboratory apparatus. Ecology, 75, 2460-2463. Norman JM, Kucharik CJ, Gower ST, Baldocchi DD, Crill PM, Rayment M, Savage K, Striegl RG (1997) A comparison of six methods for measuring soil-surface carbon dioxide fluxes. Journal of Geophysical Research, 102(D24), 28,771-28,777. Raich JW, Schlesinger WH (1992) The global carbon dioxide flux in soil respiration and its relationship to vegetation and climate. Tellus, 44(B) 81-99. Winston GC, Sundquist ET, Stephens BB, Trumbore SE (1997) Winter CO2 fluxes in a boreal forest. Journal of Geophysical Research, 102(D24), 28,795-28,804. 02/06/16 Martin et al. Do not duplicate or distribute - 13 - Figure Legend Figure 1. Schematic of the flux generation system. a diffusion medium. b radial hoses/ reference IRGA gas inlet. c reference IRGA exhaust. d internal mixing fan. e CO2 input port for elevating Ci. f boundary layer mixing fan. Figure 2. a Generated flux rates produced by the testing apparatus for one of the 5 trials. Rates were calculated by Equation 1.The nonlinear equation was used to predict generated fluxes for the times test measurements were made. b Correlation between generated and measured fluxes with all 5 trials combined. 02/06/16 Martin et al. Figure 1. Do not duplicate or distribute - 14 - 02/06/16 Martin et al. Do not duplicate or distribute - 15 - 1 2 R s = 1 1 . 2 7 2 2 * e x p ( . 0 . 0 0 0 1 5 0 6 9 5 * t i m e ) g e n e r a t e d 1 1 TestFlux( molCO 2m -2 sec -1) molCO 2m -2 sec -1) Figure 2. 1 0 9 8 7 6 5 4 GenratedFlux( 3 2 1 ( a ) 0 05 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 T i m e ( m i n u t e s ) 1 2 1 1 1 : 1 1 0 9 8 7 6 5 4 3 2 1 ( b ) 0 0 1 2 3 4 5 6 7 8 9 1 0 1 1 1 2 2 1 G e n e r a t e d F l u x ( m o l C O s e c ) m 2