2007 SIP Emission Inventory Documentation

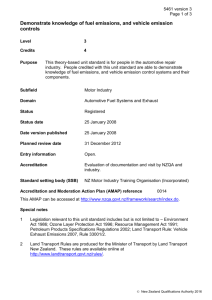

advertisement