DOC

advertisement

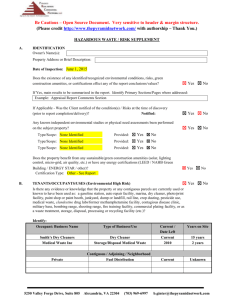

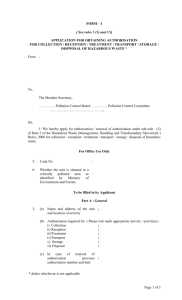

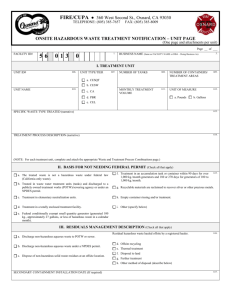

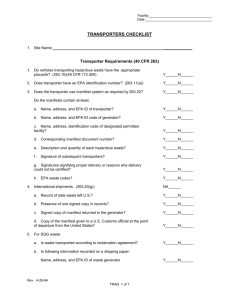

11.14. MASS HIGHWAY FACILITY SELF-AUDIT CHECKLIST Example 1: Mass Highway Facility Self-Audit Checklist Hazardous Waste 1. Are all containers closed? 2. Are all containers labeled? 3. Is the waste compatible with the container and/or its liner? 4. Are containers holding ignitable or reactive wastes located at least 50 feet from the property line? 5. Is the accumulation area delineated? 6. Is the accumulation area posted with a sign? 7. Is secondary containment provided? 8. Is sand contained within a containment area? 9. Is salt contained indoors? 10. Are hazardous materials stored in appropriate locations? 11. Are hazardous materials stored in proper containers? 12. Are all hazardous material containers closed and labeled? 13. Are MDSS and right-to-know information prominently posted? 14. Are hazardous materials stored near floor drains? 15. Are all compressed gas cylinders properly sorted (labeled, capped, chained, or in rack)? 16. Are there any leaking vehicles/equipment present? 17. Are materials other than hazardous waste present in accumulation areas? 18. Is hazardous waste present outside the accumulation area? 19. If present, are satellite accumulation area requirements being met? 20. Are emergency contacts posted? 21. Does the facility have a supply of spill absorbents available? 22. Are weekly inspections being performed? 23. Are accumulation volume limits exceeded for the generator status? 24. For SQGS only: are hazardous wastes being stored for longer than 180 days? 25. Are all self-transporting two part receipts on file? Solid Waste 1. Are bulk solid wastes stored in designated storage bins or segregated by type? 2. Are dumpsters and trash cans free of hazardous wastes, regulated recyclables, and universal wastes? 3. Is the facility free of litter? 4. Is solid waste accumulated in a natural resource area? (refer to facility plan) 5. Are there any decommissioned/ abandoned vehicles or equipment present? 6. Underground/aboveground storage tanks 7. Is there any evidence of spillage around tank fill ports or dispensing pumps? 8. Are required tank permits/registrations clearly posted at the facility? 9. For outdoor aboveground petroleum storage tanks: is secondary containment provided? 10. For aboveground storage tanks (including propane and calcium chloride tanks): are the tanks clearly placarded or labeled with their contents and NFPA ratings? 11. Are weekly stage ii vapor recovery inspections being performed? Water Quality 1. Are garage floor drains clear of debris or obstructions and functioning properly? 2. Do floor drain sumps/troughs require sediment removal? 3. Is there evidence of oil or hazardous materials entering a floor drain or catch basin? 4. For wastewater recycling systems: are the systems functioning properly? 5. For wastewater tight tanks or recycling systems: does the tank or system need to be pumped? 6. Record current volume in tank or system. 7. Is there evidence of sand or sediment entering any catch basins or other drainage structures at the facility? 8. Is the oil/water separator functioning properly Natural Resources 1. Are there any regulated wetland resource areas or waterways on or adjacent to the facility? (i.e. vegetated wetlands, banks, floodplains, land under water, and the riverfront area ) note: refer to the facility plan for confirmation. 2. Are there activities occurring which are resulting in direct impacts to a wetland resource area or waterway? Note: direct impacts include filling, excavating, dumping, or altering. 3. Are there activities occurring which are resulting in indirect impacts to a wetland resource area or waterway? Note: indirect impacts include erosion, sedimentation, or siltation. 4. Are there activities occurring within the buffer zone that are resulting in direct or indirect impacts to any vegetated wetland or bank to a waterway?