C24. NegReg_Croci

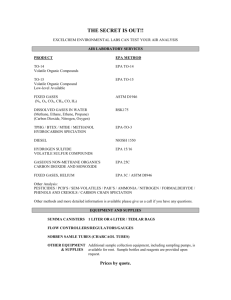

advertisement