TOXIC SUBSTANCE CONTROL ACT

advertisement

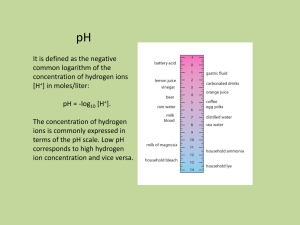

TOXIC SUBSTANCE CONTROL ACT Richard A. Mears Environmental Law November 18, 2002 The Toxic Substances Control Act, here-after referred to as TSCA was enacted by Congress in 1976 to fill the voids that were not adequately covered by other laws and regulations such as the Federal Insecticide, Fungicide and Rodenticide Act (FIFRA), The Occupational Safety and Health Administration (OSHA) and the Food and Drug Administration (FDA). In several publications, TSCA was highlighted as the regulation that allowed the federal Environmental Protection Agency (EPA) to promulgate regulations for the management, storage, use and disposal of Polychlorinated Biphenyl (PCB), but the scope of the regulation was always much more significant than people realized. TSCA was intended to more comprehensively protect both public health and the environment from unreasonable risks to a variety of hazardous materials and wastes, including biological and chemical substances, mixtures and even the byproducts of those materials. It was never limited to asbestos, lead and PCB’s This Act, because of its complexity is very confusing and difficult to follow. There are twenty-eight different, parts which include: general practices, chemical imports and exports, records and reports, pre-manufacture notifications, reporting requirements, asbestos, lead, PCB’s and identification of specific chemical substances and mixture testing requirements. It also has five very detailed sections that include test results (section 4), pre-manufacturer notifications (PMN) (section 5), reporting rules (section 8), exports (section 12), and imports (section 13), which will be detailed later in this report. TSCA requirements have been problematic for businesses, including Colleges and Universities because each believed they were exempt from the requirements, based on the fact that they were teaching or research and development facilities, not chemical manufacturers. 1 If a company, college or university does not formulate or manufacture biohazardous materials, chemicals, or generate the byproducts, then why does TSCA apply? The actual definition for manufacturers in the TSCA regulation, 15 U.S.C. Sec 2602 is “produce, manufacture, import and extract.” chemicals, which helps to clarify some of the confusion with respect to who needs to comply. Importers in the United States who receive chemicals from companies in other countries are just as responsible for complying with TSCA as are the manufacturers who formulate and market chemical substances inside our borders, or wish to ship abroad. Not every chemical is listed on the TSCA Inventory of 63,000, there are exceptions. Some chemical substances and mixtures are not required to be listed because they meet criteria, specified by EPA that makes the listing unnecessary. The quantity may be below the threshold of reporting, or it may be for scientific (non-commercial) purposes. The only way to determine whether or not the chemical you plan to manufacture, import, export or process is listed is to consult the “TSCA Inventory List.” If found on the list, the chemical can now be imported or manufactured. If the material is not excluded or exempted from the TSCA list, the manufacturer and/or importer will have to comply with the paperwork requirements, such as the PMN found in the Act. Unfortunately, the business (manufacturer, college) or importer is required to go through the motions of obtaining paperwork, filling out the required forms, testing and then documenting the information on the pre-manufacturing notice (PMN), before producing or importing a new chemical substance, which could later be deemed exempt. Another TSCA requirement is the “Significant New Use Rules (SNUR). SNUR is to be incorporated into the reporting process to help reduce the risk of exposure to humans and/or the environment. This portion of the Act applies when the EPA, under TSCA discovers that a 2 chemical substance or mixture can be used for other reasons, or has other applications that could, if not proven otherwise have adverse effects on the health and well-being of people and/or the environment. The EPA, through the above referenced Act can require the testing of both old and new chemicals, which include manufactured and synthetic chemicals, as determined by the Administrator of the EPA or their designee. Unlike any other federal requirement, the TSCA Act, which is enforced by EPA only, mandates’ testing and reporting of chemicals with dangerous characteristics or unknown toxic properties before it reaches the consumer. There is no state agency delegated to handle requirements for new, manufactured or imported chemicals. Ideally, the federal EPA, through TSCA would like to regulate the manufacture, imports, exports, distribution, process, use and disposal of all listed chemicals in commerce. “The new chemicals program functions as the gatekeeper, which can identify conditions, up to and including a ban on production, to be placed on the use of a new chemical before it is entered into commerce. Anyone who plans to manufacture or import a new chemical substance for a non-exempt commercial purpose is required under Section 5 of TSCA to provide EPA with notice before initiating the activity.” 1 Under TSCA, the EPA has strictly regulated and monitored many of the chemical substances and mixtures known to be high risk, imminent hazards, such as asbestos, dioxin’s, hydrofluorocarbons, polychlorinated biphenyls and radon contamination. These materials, which have been linked to cancer for many years, have a substantial amount of documentation to support the tight control and restriction. For reasons such as this, the EPA has the authority to mandate testing, medical monitoring, report and inventory controls and the pre-manufacturing notifications forms to protect human health and the environment from manufacturing mistakes like asbestos, dioxin’s and PCB’s. Even in recent years, after we believed we had identified and properly 3 regulated material such as asbestos, we find asbestos in children’s crayons, and in potting soil (vermiculite), or hydrofluorocarbons in “new fire suppression agents”, like Halon. Would earlier testing have prevented this from reaching the consumer? In addition to all of the exceptions referenced above, there are materials that are exempt from the requirements of TSCA, because they are regulated in detail by other federal requirements such as pesticides under the Federal Insecticide, Fungicide and Rodenticide Act (FIFRA), tobacco products, food, drugs and cosmetics under the (FDA), Radioactive Materials through the Nuclear Regulatory Commission (NRC) and firearms and ammunition which does not meet the definition of chemical substance, under TSCA. Unfortunately, one of the reasons why the TSCA regulations are confusing is that the exemptions do not stop there. The Act exempts other chemicals and substances for different reasons in other parts of this regulation, “subject to EPA approval”. For example, under 40 CFR part 723, chemicals and substances are excluded from premanufacturing notifications (PMN) requirements if they fall under one of the following categories: 1. Test Market Exemption (TME) Chemical substances in this category are exempt if they are for test marketing purposes and proposed testmarketing activity, and will not pose an unreasonable harm to the environment or human health. 2. Low Volume Exemption (LVE) After a 30 days the EPA will exempt from PMN requirements certain new chemicals manufactured in low volumes 3. Lo-Rex Exemption (low release and exposure) In conjunction with the LVE, the EPA will exempt chemical substances that are released at low levels and will not place persons at risk during production regardless of type of manufacture or volume, provided that the manufacturer or importer meets all stringent exposure and release criteria. 4 4. Research and Development Exemption (R&D) EPA exempts chemical substances from the PMN and SNUR if they are used for Research and development, in small quantities, under the direction of a qualified person. 5. Polymer Exemption New chemical polymers, which are not otherwise excluded and that meet specific exemption requirements, provided that an annual report is submitted to the EPA, with certain records being maintained. 6. Bulk Chemicals Provided that they are imported for the manufacture of food or drug products, so long as the importer certifies that the shipment is not regulated under TSCA. Not all chemical substances are regulated under TSCA, but those that are, require a certification before manufacture in the United States or prior to importation. In order to find out what chemical substances are listed under TSCA, the TSCA Inventory can be obtained from the United States Government Printing Office (USGPO) or the National Technical Information Center (NTIC) in Springfield, Virginia at order@ntis.fedworld.gov, or by phone at 703.487.4028 or 800.553.NTIS. The TSCA Inventory is a list of not only the chemical substances already recorded, but the associated health and environmental risks that have already undergone a permitting process that provides for accountability for distribution in commerce. There are numerous sections in the TSCA Act that deal with chemical substance control, five of which will be covered in greater detail than the rest. Those sections of specific interest were referenced on page one, and they appear to be the most important parts of the ACT covered by the EPA both in writing and at a majority of the training sessions held in Region 1. 5 I. Notification and Reporting Requirements When required by the Act, businesses (including companies, colleges, universities, research and development facilities, individuals etc.) must provide the EPA with information to assist with regulatory requirements, record keeping activity, inventory control, health and safety data, health and environmental effects, chemical fate, general practices and procedures, pre-manufacturing information as well as imports and exports when dealing with chemical substances that are, or have the potential to be regulated under TSCA. These reporting requirements must include; 1. Pre-manufacturing Notification (PMN), 40 CFR 720 In order to manufacture or import a chemical substance, including those that are naturally occurring, which is not listed on the TSCA Inventory, you must file a PMN with the EPA, 90 days prior to manufacture or importation of that chemical substance. The PMN will require the following information; Physical properties of the chemical or substance Quantity to be manufactured How the chemical o substance will be used How it will be distributed How it will be processed Anticipated environmental and health related risks, and Appropriate test data The PMN also asks for information on how you plan to reduce or minimize risks associated with manufacturing, processing, use and disposal of the chemical substance, although under the TSCA Act, use and disposal are not defined o Under subpart 716.50 of the Act, studies of physical and chemical properties must be performed and reported for the purposes of determining the 6 environmental or biological fate of the chemical substance, mixture and the by-products. Some of the properties that need to be evaluated are: 1. Water solubility 2. Absorption on particulate surfaces, such as soil 3. Vapor pressure 4. Water partition coefficient 5. Vapor Density 6. Specific Gravity 7. pH 8. Particle size distribution for insoluble solids 9. Dissociation constant 10. Degradation If the EPA fails to respond to your PMN or other regulatory requirements within the identified 90 period, it is acceptable to initiate manufacture, but you must submit the Notice of Commencement (NOC) to the EPA, which EPA will add to the inventory as a new chemical. The new chemicals program, which is part of EPA’s Office of Pollution Prevention and Toxics must review PMN submissions and identify new chemicals and substances that require action, under the Act. 2. Significant New Use Reporting (SNUR), 40 CFR 721 Once a chemical substance has already been placed on the TSCA Inventory, a new or additional use for that material may be identified that come affect the environment and/or human health in a way that was not previously anticipated. If the EPA believes that this material, which was already listed in the inventory, would create a “significant new use,” which may increase possible human or environmental 7 exposure, then the EPA may issue a SNUR. This specific report mandates that the manufacturer of the chemical substance give the EPA 90 day prior notice, before manufacture or importation is initiated. The SNUR must include; Possible production volume Increased potential, quantity or duration of environmental or human exposure. Distribution or manufacturing hazards This report, which is referred to as the Significant New Use Notification (SNUN) is completed and sent back to the EPA on the PMN form. This process of sending in the SNUR changes the existing chemical substance into a new material, under TSCA. 3. Preliminary Assessment Information Rule (PAIR), 40 CFR 712 Any company or individual that manufactures or imports must file a PAIR report form with the EPA for each plant site involved in the manufacturing or importing an Interagency Testing Committee (ITC)-listed chemical substance. This committee identifies those chemical substances that are suspected of causing or contributing to a form of cancer, gene mutation, or birth defects, and recommends testing considerations to the EPA. The PAIR is completed to; Provide preliminary exposure information to the EPA, so that they are better able to determine testing priorities. List production and exposure data The report must be submitted within 60 days of the chemical or substance listing o Again, depending on circumstances, not listed here in, certain small research and development manufacturers are exempt from having to complete the PAIR 8 4. Comprehensive Assessment Information Rule (CAIR), 40 CFR 712 . In 1988, the EPA provided an additional reporting form for specific substances. It was referred to as the CAIR list and only 19 substances were initially included on that list. However, in 1995 the CAIR initiative was challenged by the manufacturing industry, so the EPA repealed it, and deemed the rule(s) no longer in effect. 5. Records of Significant Adverse Reactions, 40 CFR 717 This rule, under the Act requires manufacturers and some processors who are engaged in oil refining and chemical processing to keep records of significant adverse effects on health and the environment as reported to them by their employees, customers and others, which have been caused by a chemical substance or mixture that the company manufactures, processes or imports. This significant chemical reaction must reflect substantial damage to, or impairment of normal activities, or long lasting, irreversible damage to the environment and or public health. Recordkeeping requirement only! o Should not be sent to the EPA, unless specifically requested 6. Health and Safety Studies, 40 CFR 716 TSCA requirements also mandate manufacturers, distributors, processors and importers to submit unpublished health and safety studies on specific chemical substances, mixtures and even byproducts, which are listed in 40 CFR 716.120. This means that the manufacturer or other above referenced entity shall include any health and safety related study of a chemical substance on the environment, public health or both. 9 This shall mean that any inspection, monitoring or testing, regardless of how insignificant it may seem may be considered a health and safety study by the EPA. Under section 2603, Testing of Chemical Substances and Mixtures, the Administrator of the EPA can require testing of the chemical substance for health and environmental effects. Of particular interest would be the development of a database for test data that may be used for the identification of carcinogen, mutagen, teratogen, behavioral disorders, such as those that were attributed to lead based paint Cumulative or synergistic effects and any other effect, which may present an unreasonable risk of injury to health or the environment The administrator would be checking for those chemical substances or mixtures for which standards may be prescribed including acute toxicity, subacute toxicity , chronic toxicity and any other characteristic that may present a health risk o After all documentation has been received and reviewed, the Administrator shall give the interested persons an opportunity for a presentation of date, their particular views and arguments, in addition to making written submissions o To assist the Administrator, Congress established the Interagency Testing Committee (ITC) to make recommendations about the chemicals and the testing procedures. The committee must consider all key factors, such as… Quantities being manufactured How the material will enter the environment The number of people that may be exposed to the material Duration of exposure How closely the material resembles or reacts to a known material The amount and type of testing that will be required 10 7. Substantial Risk Information The Act also requires, manufacturers, distributors, processors and importers of chemical substances to report any information to EPA that “reasonably supports the conclusion that there is a substantial risk of personal injury to the health and wellbeing of a person, or the environment, which is or can be linked to the chemical substance that is being manufactured, processed, distributed or imported. It is possible, under this act, that company officials and their employees can be held liable, unless specific complex procedures are followed and enforced. Proposed Chemical Reporting Rule - Recently the EPA drafted a new rule, under TSCA that would require manufacturers and importers to file information on chemical use and employee exposure. This report will have to be performed every four years, in order to better monitor worker exposure. A reporting threshold of 10,000 lbs per facility has been suggested Should the Administrator, through the committee identify a chemical substance or mixture that will present an unreasonable risk of injury to health or the environment, the Administrator shall apply one of the following requirements: a. prohibit the manufacture, process or importation of the chemical substance or mixture, or b. limit the amount of the material that can be manufactured, processed or distributed in commerce If limitation of the material is to be controlled, the Administrator shall have the authority to… 11 give public notice about the material being manufactured, processed or imported to processors, distributors and the general public, as necessary. Monitor quality control Reduce the risk of injury to health and the environment as is prudent and reasonable. 8. Inventory Update Report (IUR), 40 CFR 710 Manufacturers and importers of chemical substances that are in excess of 10,000 lbs at any time during the most recently completed corporate fiscal year shall have to report criteria on the plant site, production volume and site limited status. 9. Microbial Commercial Activity Notice (MCAN), 40 CFR 725.155 and (TERA), 40 CFR 725.255 for Experimental Releases. This section is part of TSCA’s biotechnology regulation. It was specifically required for microorganism reporting. MCAN’s must be submitted to the EPA 90 days before new microorganisms are used TERA’s should be submitted to the EPA 60 days before initiating field trials of new microbes 10. Import and Export Notification, 40 CFR 707 Manufacturers, processors, distributors and importers/exporters of chemical substances are required to follow several TSCA requirements as referenced in the Act. 12 o Exception – under part 712.28 persons who qualify as a small manufacturer or importer with respect to a specific chemical substance or mixture listed in 712.30 are exempt from reporting requirements. However, this exception does not apply with respect to a chemical substance or mixture that is found in 712.30, which is designated by an asterik. Import Certification o Any manufacturer, processor, distributor or importer of chemical substances referenced in the Act shall follow the stipulations identified in TSCA. o Although EPA is responsible for the implementation of most of the TSCA regulations, the Act specifically identifies the United States Customs Service as the agency responsible for the importation and control of chemical substances entering the country. Any importer is required to provide the USCSB with written documentation that the chemical substances in transit do not violate TSCA rules, specifically 19 CFR 12.121(a). Before any new chemical substance is imported, the importer must have already complied with the requirements of TSCA’s PMN. Exception – the EPA, and not the United States Customs Service Bureau regulate hydrofluorocarbons that are imported, unlike other chemical substances, which are controlled by the USCSB. 13 Importers of certain HCFC’s are required to provide the EPA with hydrofluorocarbon information as it pertains to health and safety. This requirement includes the 90-day prior notice that all importers of HCFC 133a and HCFC-132b submit all appropriate paperwork before receiving either of these chemicals. Export Information The Act requires anyone who exports chemical substances to follow TSCA requirements. If any business plans to export a chemical substance or mixture regulated under TSCA, it must notify EPA within 7 days of exportation, or “forming the intent to export the chemical” (whichever comes first), if this is the first time that the material is being exported in a calendar year, to the same country Exception – the EPA, not the USCSB receives exporters notification Additional exceptions 1. Notification is not required if the material being exported is an article, unless that article contains PCB’s 2. If a manufacturer or processor was prohibited from exporting chemical substance under section 5 or 6, they could notify the EPA under section 12(b), and then export. 14 II. Inspection, Enforcement and Penalties 1. Inspections Under the provisions of the Act, EPA agents can inspect manufacturers, processors, distributors and importers premises, vehicles, records and paperwork for compliance with TSCA. The agency could obtain, if necessary an administrative search warrant when access to the facility or piece there-of has been denied. The EPA agent can… a. Subpoena witnesses b. Confiscate documents and records c. Seize immediately hazardous materials, and d. Halt the production of processes 2. Non-Compliance, Civil and Criminal Penalties Any company, business, distributor, manufacturer, processor and/or importer that fails or refuses to comply with any EPA order, including TSCA can receive both criminal sanctions with imprisonment of up to one year and monetary fines in the amount of $25,000.00 per day. The infractions could be for improper recordkeeping, failure to file reports, notices and other pertinent information. Citations could also be levied for failing to provide an inspector access to records, or to use for commercial purposes a chemical substance or mixture that was know to be manufactured, processed or imported in violation of TSCA, section 5 or 6. 15 Should the Administrator identify, or otherwise be notified of an imminently hazardous chemical substance or mixture, he or she may commence a civil action in U.S. District Court for seizure of the material and/or any other appropriate relief, including temporary or permanent injunctions, mandatory injunction, recall, and repurchase of the substance by the manufacturer, processor or distributor. III. Laboratory Requirements as they pertain to the Act, known as TSCA Laboratories, including those that are engaged in research and development must be familiar with the requirements of TSCA. o The EPA shall require that we protect human health and the environment from the negative effects of chemical substances and mixtures. The responsibility to properly address the manufacture, production and transport of these chemicals shall fall on the manufacturers, processors and importers, with EPA oversight, as required or as is necessary. o Chemicals that are regulated under TSCA shall include: “Any organic or inorganic substance of a particular molecular identity including any combination of such substances occurring, in whole or in part, as a result of a chemical reaction or occurring in nature and any element or uncombined radical.”2 16 o Research and Development Exemption: Chemical substances are exempt from many of the requirements of TSCA, when… a. the chemical is imported, manufactured or used in small quantities, and b. it will strictly be used for non-commercial scientific experimentation, analysis or research, and used under the direct supervision of a technically qualified individual. o In order to maintain a TSCA approved Research and Development Laboratory, in exempt status, the facility must… a. Certify the TSCA status of all imports for the R&D facility, in writing b. Notify all receiving companies of exports within 7 days, in writing c. Label all containers, the shipping containers they are packaged in, and attach the shipping papers for any substance shipped for R&D purposes, in the United States. i. Communicate all risks (known or potential) using labels, Material Safety Data Sheets and Shipping Papers d. Create and maintain all records for future information. It is especially important to identify effects to human health and the environment which may be caused by the substances found in the R&D laboratory 17 e. Document and support any significant risk to health and the environment, as it may be associated with the R&D facility. f. Grants used for funding must specify that the money has been made available for research activities, and not for commercial purposes. o To ensure proper compliance with the Act, TSCA requires laboratory groups or types of operation to complete the following steps: 1. Determine whether or not TSCA applies to your laboratory facility 2. Identify a TSCA coordinator for the laboratory 3. Establish a TSCA compliance file for administrative and recordkeeping purposes. The file must contain the following: a. TSCA applicability form b. Import Certifications c. Import and Export Notifications d. Inter-facility shipping records e. Significant adverse health and environmental effect log f. Substantial risk reports 4. Develop a process for review of TSCA applicability & compliance. o Recordkeeping is especially important for R&D facilities, if they would like to maintain the TSCA exceptions. Unfortunately, this process is labor intensive and can be very overwhelming for the designated TSCA compliance person. As stipulated under section 8 of the Act, the designated person(s) must keep detailed records of all 18 correspondences, applications, forms and exceptions for each chemical substance or mixture, as well as the adverse health risks, potential injury to the environment, and any complaints received by an aggrieved party. These records must be maintained for a period of not less than five (5) years, if prepared by someone outside the business, or for not less than 30 years, if performed in house. TSCA regulations and requirements are not only overwhelming in terms of work, but extremely confusing as well. The exceptions, counter-exceptions and poorly defined definitions, and terminology make it a very difficult “Act to follow.” It is very easy to understand why laboratories felt that they were exempt from the requirements identified here-in. If you were unfamiliar with the actual definition of manufacturer, you would have no way of knowing that you or your facility is out of compliance. “If EPA’s regulations implementing the various subsections of TSCA applied to everyone who fell within the literal language of these broad definitions, TSCA requirements would be imposed on thousands of businesses that Congress never intended the law to touch”3 Another key issue is the need to have a copy of the actual TSCA Inventory. Without this piece of information (63,000 chemicals) the manufacturer, processor and/or importer would not know if the chemical substance or mixture was “listed”, as required. If you opted to export, seek commercial benefit or otherwise modify a chemical or substance, without proper EPA awareness, under TSCA, then serious penalties, both criminal and financial could befall upon the facility, laboratory, manufacturer, processor, importer or distributor. Consequences could include inability to continue research, loss of product, reduction of resources, confiscation of property, loss of grants and future work etc. Awareness of TSCA rules and regulations under the Act is painful, but necessary. 19 1. The New Chemicals Program functions as the “gatekeeper….” New Chemicals Program, U.S. Environmental Protection Agency www.epe.gov/opptinr/newchems/index.htm 2. Chemical Substances regulated by TSCA include: Toxic Substances Control Act (TSCA) Fact Sheet, EH&S TSCA website (no other information available) 3. Environmental Law Handbook, 16th edition, Page 526 Additional Resources Environmental Management, 2nd Edition, National Safety Council – Copyright 2000 Code of Federal Regulations, 40 CFR – Chapter I, Part 700-799 US Code Collection, Title 15, Chapter 53 – Toxic Substances Control Act, Legal Information Institute, www4.law.cornell.edu/uscode/15/ch53.html Toxic Substances Control Act (TSCA), Statute 15 U.S.C. sec 2601-2692, www.ntc.blm.gov/learningplace/res_TSCA.html Prudent Practices in the Laboratory, Second Printing, National Academy Press, - Copyright 1999., Pages 200, 210-212. Toxic Substances Control Act – Related Internet Sites New Chemicals Program, U.S. Environmental Protection Agency www.epe.gov/opptinr/newchems/tscasite.htm Core TSCA Region 1: New England U.S. Environmental Protection Agency www.epa.gov/region01/compliance/enftsca.html Risk Assessment in the Workplace, Section 2 Worker Education and Training, Section 4 The Occupational Environment – Its Evaluation and Control, A publication of the American Industrial Hygiene Association – Copyright 1997 US Code Collection, Title 15, Chapter 53, Subsection I – Control of Toxic Substances, Legal Information Institute, 20 www4.law.cornell.edu/uscode/15/ch53schI.html Subchapter R – Toxic Substances Control Act, Laws and Regulations, U.S. Environmental Protection Agency www.epa.gov/docs/epacfr40/chapt-I.info/subch-R.htm 21