1 SOLVENT EXTRACTION OF Au(III) BY THE CHLORIDE SALT OF

advertisement

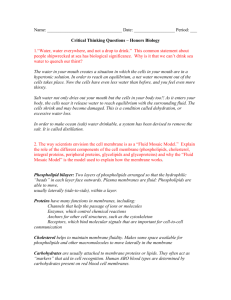

SOLVENT EXTRACTION OF Au(III) BY THE CHLORIDE SALT OF THE AMINE ALAMINE 304 AND ITS APPLICATION TO A SOLID SUPPORTED LIQUID MEMBRANE SYSTEM F.J.Alguacil Centro Nacional de Investigaciones Metalúrgicas (CSIC), Avda. Gregorio del Amo 8, Ciudad Universitaria, 28040 Madrid, Spain. E-mail: fjalgua@cenim.csic.es ABSTRACT The extraction of Au(III) by the chloride salt of the amine Alamine 304 (R3NH+Cl-) in xylene from hydrochloric acid solutions has been investigated. The analysis of metal distribution data by numerical calculations suggested the formation of the species R3NH+AuCl4- in the organic phase with formation constant log Kext= 5.44. The results obtained on Au(III) distribution have been implemented in a solid-supported liquid membrane system, where in NaSCN solutions were found to be the most effective to strip the metal from the organic solution. Influence of membrane composition, metal concentration on gold transport, and the selectivity of the system have also been studied. INTRODUCTION Extraction of gold from an aqueous halide medium into an organic phase has been frequently used for both the separation and concentration of this precious metal. In fact, the technology has been implemented in various flow sheets aimed at the separation and concentration of gold and platinum group metals (PGM) (1,2). Due to the reactivity of the gold(III)-chloro complex, several studies had dealt with using various types of extractants such as amines (3-7), phosphine oxides (8-10), and reagents containing sulphur (11-15) or oxygen (1,16) as donor atoms. These extraction systems can also be implemented in a solid-supported liquid membrane, where the performance of solvent-extraction separation is enhanced by combining the extraction and stripping processes in one step (17,18). Though scarce, various applications of these extraction systems to membrane transport of gold have been considered (19-24). The present investigation was undertaken to obtain quantitative characterization of the extraction reaction between aqueous Au(III) and the chloride salt of the amine Alamine 304 in xylene. Moreover, a liquid-membrane system has been designed by using the extraction process mentioned above, and parameters affecting the liquid membrane, i.e. stripping reagent, composition of the membrane phase and metal concentration have been studied. 2 EXPERIMENTAL Reagents and solutions A 1000 mg L-1 stock solution of Au(III), was obtained by dissolving HAuCl4 (Fluka) in distilled water. The working solutions, containing various gold(III) concentrations in 6 M HCl, were prepared by dilution of the stock gold solution in HCl-water solutions. The chloride salt of the amine Alamine 304 (Cognis) was prepared as described in the literature (25), diluted in xylene (AR grade, Fluka), and used as the organic phase. Various concentrations of the organic salt were also used in the investigation. Apparatus and Procedure Solvent extraction experiments Distribution batch experiments were carried out at 20C by shaking (700 rpm) equal volumes (25 mL) of the organic phase and the aqueous solutions in separatory funnels. After equilibrium, the metal remaining in the aqueous phase was analysed by atomic absorption spectrophotometry (AAS) (Perkin Elmer 1100B spectrophotometer). The amount of metal extracted was obtained by difference with the initial concentration in the aqueous solution. The validity of the procedure was checked by complete stripping of several gold-loaded organic phases using a thiocyanate (0.5 M) solution and analyzing the gold concentration in the stripped phase. After applying the corresponding mass balance, 96% mass balance accuracy were regularly obtained. From these data, the distribution coefficient, D, was calculated as the ratio D= [Au(III) ]org [Au(III) ]aq (1) where [Au(III)]org and [Au(III)]aq are the total gold concentration in the organic and aqueous phases, respectively. Liquid membrane system Permeation experiments were carried out in a two-compartment membrane cell described elsewhere (26), where 200 mL aqueous solution containing different gold concentrations in 6 M HCl was used as the source solution. For the stripping phase, the same volume of NaSCN 0.5 M was used. The support for the liquid membrane was a polyvinylidenedifluoride (PVDF) film (Millipore GVHP) with thickness (dorg) of 125 μm, 75% porosity (ε), 0.22 μm average pore size, tortuosity (τ) 1.67, and effective membrane area 11.3 cm2. 3 The liquid membrane was prepared by impregnating the laminar microporous film with solutions of the chloride salt of the amine Alamine 304 in xylene, whereas both aqueous phases were pre-saturated with xylene in order to stabilize the membrane phase. In each experiment, stirring rate in both the source and stripping solutions was kept constant at 1200 rpm. The metal concentrations in the aqueous solutions were periodically determined by means of AAS. The metal flux, J, was calculated as (2) J = P [Au(III) ]TOT where [Au(III)]TOT is the metal concentration in the source phase, and P is the permeability coefficient which was calculated as (27) Cdt A Pt ln (3) Cd0 V RESULTS AND DISCUSSION Solvent extraction system A preliminary investigation was carried out in order to determine the time needed to obtain equilibrium. From experiments carried out using an aqueous phase containing 50 mg L-1 Au(III) and 6 M HCl and the amine salt 3x10-3 M in the organic solution, it was observed that equilibrium is reached after 1 minute of mixing. Nevertheless, the contacting time was fixed at 10 minutes. The metal distribution ratio, D, at 6 M HCl, was determined for different amine salt concentrations at different Au(III) concentrations. Results are plotted in Fig.1. It can be seen that log D depends on the gold concentration, and increased as the initial metal concentration decreased. Taking into consideration that Au(III) exists mainly as tetrachloroaurate(III) ion (28,29), AuCl4-, it can be assumed that gold(III) is extracted by the chloride amine salt (R3NH+Cl-) according to the following ion exchange reaction AuCl 4aq + R3 NH Clorg R3 NH AuCl 4org + Claq - + - + - - (4) Assuming ideal behaviour in the organic phase and constant activity coefficient in the aqueous phase, the equilibrium constant for eq.(4) can be written as K ext = [R 3 NH+ AuCl -4 ]org [Cl- ]aq [AuCl -4 ]aq [R 3 NH+ Cl- ]org (5) It is known that amines and quaternary ammonium salts tend to form aggregates in organic 4 phases (30). Aggregation depends strongly on the organic diluent and the extractant concentration. In this investigation, very dilute solutions of reagent have been used, so it could assume that, though the amine salt aggregates (31), the monomer form of the amine salt predominates in the organic phase, and the behaviour shown in Fig.1 may be explained taking into account the following set of equations. The total concentration of the amine chloride in the organic phase is [R3 NH+ Cl- ]total = [R3 NH+ Cl- ]org + [R3 NH+ AuCl -4 ]org (6) and from eq.(5), the next expression is obtained + K ext [AuCl 4 ]aq [R 3 NH Cl ]org [R 3 NH AuCl ] = [Cl- ]aq + 4 org (7) Substitution of eq.(7) in eq.(6) leads, after re-arranging to [R 3 NH+ Cl- ]org = [R 3 NH+ Cl- ]total K ext [AuCl 4 ]aq 1+ [Cl- ]aq (8) From eq.(5), considering the definition of the distribution coefficient (eq.(1)), taking logarithms and re-arranging, the following expression is obtained log D = log K ext + log [R3 NH+ Cl- ]org - log [Cl- ]aq (9) From eq.(8), as the gold concentration in equilibrium is increased, the concentration of the amine chloride in the equilibrated organic phase becomes lower, and thus in eq.(9), the value of log D also becomes lower (Fig.1). To determine the composition of the extracted species and their extraction equilibrium constants, extraction data were also numerically treated by using the LETAGROP-DISTR program (32); in the program the error square sum U over all Np ( 27 experimental points) defined as U = N p (log D cal - log D exp )2 (10) was used in the minimization process. Dexp represents the experimental distribution coefficient and Dcal is the value calculated by the program for the model tested after solving the mass balance equations of the components of the system. Therefore, the best model is the one which gives the lowest value of U. The calculations were performed taking a set of species and extraction constants as the starting input and considering the 5 influence of the minimized function when partially varying or adding new species to the model. Furthermore, data on the formation of trimers by the amine salt (log K3 = 3.18) (31) were also considered in the numerical treatment of the data. The results of computer analysis showed that the extraction system is best fitted to the existence of one species, with stoichiometry R3NH+AuCl4- (as shown in eq.(4)), in the organic phase with log Kext = 5.44±0.12 (σ(log Kext)= 0.04) and U= 0.19 (σ= 0.13). Liquid membrane system The extraction system of tetrachloroaurate(III) ion by the chloride salt of amine Alamine 304 has been implemented in a solid-supported liquid membrane, where the transport of metal species across the liquid membrane depends not only on the equilibrium distribution ratios but also on the kinetics of extraction and stripping processes. The transport of Au(III) through the liquid membrane has been studied by varying the chemical conditions of the three phases: stripping and source aqueous solutions and the membrane phase. The selectivity of the system was also investigated. Best stripping conditions are essential to apply the extraction system studied to a membrane transport system. Several reagents were tested as stripping solutions for Au(III) from the loaded organic phase. Coordinating ligands, as thiourea and thiocyanate, reducing agents like NaHSO3, and other salts (NaClO4) or even water have been used. As can be seen in Fig.2, the stripping ability for Au(III) decreases in the order NaSCN>NaClO4>water>thiourea>NaHSO4. Sodium thiocyanate was found to be the most efficient stripping agent. The transport of Au(III) through the membrane against its concentration gradient was achieved, recovering practically all the metal in the stripping compartment after 3 hours. Thiocyanate ion strips gold due to the strong complex ability of thiocyanate (log ß3= 42) (28) towards the metal. The influence of the membrane composition on gold transport was studied using different carrier concentrations in the membrane phase. Figure 3 shows metal flux values for the transport of gold through a supported liquid membrane impregnated with solution 0.01-0.7 M of the amine salt in xylene. Lower concentrations of carrier were investigated, and no transport was achieved. The metal flux value increased with the amine salt concentration and then levels off, this being typical of a process controlled by diffusion in the stagnant film of the source phase. In this condition (33) J lim = Daq [Au(III) ]TOT d aq (11) 6 -6 2 -1 and assuming a value of 7.2x10 cm s for the aqueous diffusion coefficient of the goldcontaining species (Daq) and Jlim equal to 7.7x10-10 mol cm-2 s-1, the thickness of the aqueous diffusion film (daq) estimated from the above equation is 1.0x10-3 cm. The influence of the initial Au(III) concentration at 6 M HCl in the source phase on transport across the supported liquid membrane containing 0.1 M amine salt in xylene is shown in Fig.4. At low gold concentrations, the average metal flux is a function of the initial metal concentration in the source phase. Hence, the permeation process is controlled by diffusion of gold species in the lower range of metal concentrations. However, beyond a certain limiting concentration, the flux tends to be independent of the metal concentration, the most probable reason for this may be the rate-determining step for the transport process. Under the limiting condition the total concentration of the amine salt becomes equivalent to [R3NH+AuCl4-]org, and on the basis of the next equation (34) + - Dorg [R 3 NH AuCl 4 ]org J lim = d org n (12) where n is the stoichiometric coefficient of the reaction and dorg is the thickness of the membrane, the value of the membrane diffusion coefficient, Dorg, is estimated to be 9.6x10-8 cm2 s-1. The diffusion coefficient of the gold complex in the bulk organic phase, Dorg,b, can be evaluated from the diffusivity (Dorg) in the membrane phase (35) 2 Dorg,b = Dorg (13) the value of Dorg,b was calculated to be 3.6x10-7 cm2 s-1. It should be noted that in the present system, Dorg presents a lower value than that of the bulk diffusion coefficient, this is attributable to diffusional resistance caused by microporous thin membrane placed between the source and stripping phases. The selectivity of the Au(III)-amine salt over Fe(III), Cu(II), Zn(II) and Ni(II) has also been analyzed. Transport experiments have been carried out using a liquid membrane of 0.1 M amine salt dissolved in xylene and a source phase which contained 10 mg L-1 of each metal in 6 M HCl. Table 1 shows the values of the selectivity factors, ß, obtained for the present investigation. These values were estimated according to the following (36) = J Au [M ]0 J M [Au ]0 (14) where J represents the metal flux and [Au]0 and [M]0 are the respective metal concentrations in the source phase at time zero. The values indicate that gold is transported 7 by the amine salt, preferably to the other metals with quantitative separation over Cu(II) and Ni(II). ACKNOWLEDGEMENTS This work has been carried out under the support of CSIC (Spain). Technical assistance by Mr.Bascones and Mr.López is also thanked. REFERENCES 1.M.Cox, Principles and Practices in Solvent Extraction, J.Rydberg, C.Musikas and G.R.Choppin (eds.), Marcel Dekker, New York (1992). 2.R.A.Grant and V.A.Drake, Proc. of ISEC´02, K.C.Sole, P.M.Cole, J.S.Preston and D.J.Robinson (eds.), The South African Institute of Mining and Metallurgy, Cape Town (2002). 3.I.Villaescusa et al., Solvent Extr. Ion Exch., 11, 613 (1993). 4.F.J.Alguacil and C.Caravaca, Hydrometallurgy, 34, 91 (1994). 5.I.Villaescusa, V.Salvadó and J.de Pablo, Hydrometallurgy, 41, 303 (1996). 6.S.Martínez, A.M.Sastre and F.J.Alguacil, Hydrometallurgy, 52, 63 (1999). 7.F.J.Alguacil, S.Martínez and A.M.Sastre, J. Chem. Res. (S), , 384 (2001). 8.S.Martínez et al., Hydrometallurgy, 40, 77 (1996). 9.M.A.Barroso et al., Hydrometallurgy, 45, 199 (1997). 10.S.Martínez, A.Sastre and F.J.Alguacil, Hydrometallurgy, 46, 205 (1997). 11.V.Salvadó et al., Solvent Extr. Ion Exch., 8, 491 (1990). 12.G.Zuo and M.Muhammed, Sep. Sci. and Technol., 25, 1785 (1990). 13.M.Petrich et al., Solvent Extr. Ion Exch., 11, 51 (1993). 14.S.Martínez et al., Hydrometallurgy, 43, 1 (1996). 15.F.Z.El Aamrani et al., Solvent Extr. Ion Exch., 16, 1389 (1998). 16.A.Madi et al., Proc. of ISEC´96, D.C.Shallcross, R.Paimin and L.M.Prvcic (eds.), University of Melbourne, Melbourne (1996). 17.P.R.Danesi, Sep. Sci. and Technol., 19, 857 (1984). 18.L.L.Tavlarides, J.H.Bae and C.K.Lee, Sep. Sci. and Technol., 22, 581 (1987). 19.J.Fu, S.Nakamura and K.Akiba, Anal. Sci., 11, 149 (1995). 20.F.Z.El Aamrani et al., Hydrometallurgy, 50, 315 (1998). 21.A.Sastre et al., J. Membr. Sci., 139, 57 (1998). 22.F.J.Alguacil et al., Chem. Eng. Sci., 56, 3115 (2001). 23.G.Zuo, S. Orecchio and M.Muhammed, Sep. Sci. and Technol., 31, 1597 (1996). 24.V.Salvadó et al., Anal. Lett., 22, 2613 (1989). 8 25.F.J.Alguacil, A.López-Delgado and F.López, Rev. Metal. Madrid, 36, 165 (2000). 26.F.J.Alguacil and M.Alonso, Hydrometallurgy, 58, 81 (2000). 27.F.J.Alguacil and P.Navarro, Hydrometallurgy, 61, 137 (2001). 28.J.Marsden and I.House, The Chemistry of Gold Extraction, Ellis Horwood, Chichester (1992). 29.I.Puigdomenech, Medusa Program, Royal Institute of Technology, Stockholm (2002). 30.G.M.Ritcey and A.W.Ashbrook, Solvent Extraction, Vol.I, Elsevier, Amsterdam (1984). 31.E.Högfeldt, Developments in Solvent Extraction, S.Alegret (ed.), Ellis Horwood, Chichester (1988). 32.D.H.Liem, Acta Chim. Scand., 21, 1521 (1971). 33.F.J.Alguacil and S.Martínez, J. Chem. Technol. Biotechnol., 76, 298 (2001). 34.R.Mahapatra, S.B.Kanungo and P.V.R.B.Sarma, Sep. Sci. and Technol, 27, 765 (1992). 35.T.-C.Huang and R.-S.Juang, J. Chem. Technol. Biotechnol., 42, 1 (1988). 36.F.J.Alguacil and A.M.Sastre, J. Chem. Technol. Biotechnol., 75, 577 (2000). TABLE 1. SEPARATION FACTORS USING THE AMINE SALT AS CARRIER ___________________________________________________________________ ßAu/Zn ßAu/Fe ßAu/Cu ßAu/Ni __________________________________________________________________ 21 10 quantitative quantitative ___________________________________________________________________ Stripping phase: 0.5 M NaSCN FIGURE 1. Experimental distribution data, log D vs log [R3NH+Cl-]org at different metal concentration. FIGURE 2. Investigation of stripping conditions for Au(III). Source phase: 10 mg l-1 Au(III) and 6 M HCl. Membrane phase: 0.1 M amine salt in xylene. Stripping phase: 0.5 M stripping reagent. FIGURE 3. Metal flux versus carrier concentration. Source phase: 10 mg l-1 Au(III) and 6 M HCl. Stripping phase: 0.5 M NaSCN. FIGURE 4. Effect of metal concentration on metal flux. Membrane phase: 0.1 M amine salt in xylene. Stripping phase: 0.5 M NaSCN.