Production of Activated Carbon from Spent Lubricating Oil by

advertisement

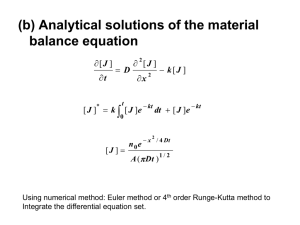

National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء Production of Activated Carbon from Spent Lubricating Oils by Chemical Treatment Ammar A. Hamdon Dept. Chem.,/ College of Education, University of Mosul (NJC) (Received on 25/1 /2005) (Accepted for publication on 22/ 6/2005) Abstract In this work activated carbon of a good quality prepared from spent lubricating oils using oxidation condensation process. The oxidation of the spent lubricating oils conducted using 2% (wt%) of (CoCl2, ZnCl2 & FeCl3) and in the presence of a stream of air or oxygen. The reaction mixture was heated at 350C for (12, 24 & 36) hr, this followed by removal of uncarbonized materials under reduced pressure. The carbonization and activation was conducted at 55025C for 3 hrs and the ratio of the feedstock to NaOH (1:2). After the carbonization was completed, the reaction mixture was subjected to purification by treatment with distilled water, 10% HCl and distilled water till it gives neutral test to litmus paper. The samples were dried at 120C for 24 hr and its physical properties were determined, the research work indicated that a good quality activated carbon was obtained when the oxidation of sample was conducted using 2% FeCl3 for 36 hr. الخالصة يتضمن البحث تحضير الكاربون المنشط من الزيوت المستتللكة عتن طريتج اجتراء عمليتة اكستد تكاثفيتة و24 ،12 لمتتد350 ) وام ترار تيتتار متتن الل تواء عنتتدFeCl3 وZnCl2 ،CoCl2 وزن تان متتن%2 باستتتادا يلي ذلت عمليتة ا ازلتة للمتواد ايتر الم ربنتة باستتادا التقطيتر الف اراتي بمتد ذلت يتت مفاعلتة مالفتات، ) ساعة36 م ت تتاد اولي ت تتةد يدرو س ت تتيد ال ت تتوديو عن ت تتد،)2:1 التقطي ت تتر الف ارا ت تتي م ت تتو زي ت تتاد م ت تتن يدرو س ت تتيد ال ت تتوديو ستتاعات يتتت تنقيتتة المتتاد الناتجتتة عتتن طريتتج القستتل بالمتتاء المقطتتر لحتتين التمتتاد ومتتن ث ت3 لمتتد25550 يلي ذل، حامض الليدرو لوري وباستادا عملية الت ميد الحراري لمد ساعة واحد%10 المماملة مو محلو ، ستاعة24 لمتد120 تجفف النماذج عند عملية ترشيح للماد الكاربونية واسللا بالماء المقطر لحين التماد يلي ذل عملية تحديد موا فات الكاربون المنشط المحضتر ومقارنتلتا متو تاربون منشتط تجتاري متن انتتاج شتر ة B.D.H 216 National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء by heating the feedstock under vacuum Introduction Activated carbon, also called to produce a “char”. The char is then charcoal, is greatly involved in recent activated by exposure to an extremely civilization. It is employed in the hot gas, usually at about 800-1000C, production of many products of great which may help to open the pores of need every day; to remove impurities all its type, by reaction with unrequired that cause an objectionable colour, atom in the structure. The feedstock taste, from selected plus the manner in which it’s drinking water and nutrients. Removal carbonized and activated, determines of leathal gas in the chemical ware fare the characteristics of the finished (gas masks) and to separate/purify activated carbon product and its cost. products and There are dozens. Of different kinds of pharmaceutical industries. Activated activated carbon produced; of these carbon covers a family of materials only a handful will be well valuable to made from carbon which have the any particular application(1). odour, in heavy the metals chemical ability to attract and hold certain The literature contains many substance on the carbon surface. This research work concerning activated ability is called “adsorption”. The carbon, which may include source of adsorption process is an example of the feedstock, nature of carbonization what is termed “chemical filtration”, processes, type of activation methods where certain dissolved substance are and texture of the product activated removed from the water. Filter floss, carbon which is given as follow; on the other hand O’Grady performs and Wennerbery, “mechanical filtration” by trapping prepared solid particles suspended in the water. exceptionally high surface area over 2500 The Feedstock most commonly activated m2/gm and carbon having extraordinary used to produce the carbon are coal, adsorptive capacities. The carbon is petroleum residue and asphaltenes, made by a direct chemical activation in peat, lignite, wood and other plants which petroleum coke and other harvesting products. These feedstock carbonaceous sources are reacted with containing recognizable amount of excess KOH at 400-600C(2). Gercia et. carbon. other al., prepared activated carbon from unrequired components are driven of mixing pine wastes with KOH in a The hydrogen and 217 National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء pilot gasifier, without any previous with (5%) NHCl and finally with treatment. different distilled water till neutral litmus paper alkali/char ratios varied from 1:1 to 1:4 is indicated. Then the sample dried at at 725-800C. After the activation 110C for 24 hr(3). Ceren and Meral, process, the sample was cooled under prepared Activated Carbon as given N2 and washed sequentially five times below(4); They employ Char Coal Crushing Cooling Purification by 1-10%HCl 2-D.W. 3-0.5NHCl 4-Hot D.W. 5-Cold D.W. Activated with ZnCl2 (24 hr, R.T.) Carbonization at 500,600&700C for 1 hr. Drying (105C) Drying (105C) Grinding (0.125-0.250mm) Sieving Chipofy and McConnachie area and pore volumes as high as 2900 from m2/gm and 1.7 cm3/gm, respectively agricultural waste. Production involved with high yields of approximate 30% carbonization of set quantity of the Wt(6). Kobayashi et. al., prepared precursors in stainless steel trays that activated carbon from brown coal and were in turn placed in a stainless steel weathered coal with a relatively large box and heated in a steam atmosphere quantities of sodium hydroxide or at 600, 650, 700, 750 and 800C, potassium hydroxide (alkali ratio to 10C for 30 minutes. Steam was coal 2-2.5) under low temperature generated by pumping water from a 20 (500-700)C than the conventional liter jar into the steel box at different steam activated (900-1000)C. For feed rates(5). Teng and Weng, prepared instance, active carbon with specific activated carbon from mesophase pitch surface area of more than 1000m2/gm powders by heat treatment and KOH were etching at temperature 427C. The (33-36%), when weathered coal was activated carbon obtained has a surface activated by NaOH (ratio 2.5-3.0) at prepared activated carbon 218 obtained with high yield National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء 700C. the effect of alkali could be, of air or oxygen at 350C for 3 hrs. improved significantly by pre-heating The carbonization and activation was at 500C of coals, affording the active conducted at 55025C for 3 hrs using carbon with higher values of specific excess NaOH(10). Al-Ghanam, et. al., surface area (1300m2/gm) at 550C(7). prepared activated carbon from (Heet Aweed, prepared activated carbon asphalt) using several percentage of from residual petroleum products such poly ethylene in the presence of air at as that of qaiyarah heavy crude oil (S 350C for 3 hrs and then complete the about 7.45%) by employing direct carbonization oxidation with and/or by using certain 55025C using excess NaOH(11). Al- type of catalysts (CoCl2, ZnCl2 and Ghanam, et. al., prepared activated FeCl3) at 350C. Activation of the carbon from heavy petroleum residue carbon after oxidation carried out at using chemical treatment. The activity about 55025C by using different of carbon was performed through percentage of KOH. Catalysts used in adsorption of acids in aqueous(12). the research (CoCl2 & ZnCl2) give a Experimental good result but not as the same as that 1- and Treatment activation of at Spent (8) of FeCl3 . Lubricating Oils Prinsloo and Jiger, prepared Exactly weighed (100gm) from activated carbon by the chemical and spent lubricating oils were treated with physical activation. Coke precursors 2% (Wt%) of (CoCl2, ZnCl2 & FeCl3). (uncalcined) produced from waxy oil The mixture was heated gradually till and medium temperature pitch were 350C and kept for a period of 12,24 & activated between 0.5 & 9 base coke ratio, 600-800C heat 36 hr. Air was continuously passes treatment during the heating period. The product temperature (HTT) and 1.5 and 12 hr heat treatment time (HTt). from the oxidation was allowed to cool All to room temperature. Unreacted part of activation and cooling cycles were the spent lubricating oils were removed carried out under a constant flow of nitrogen(9). Rhamadhan et. by distillation under vacuum. The al., residual materials left behind were prepared activated carbon from (Beje used as a feedstock for the activated asphalt) using several percentage of carbon preparation. V2O5 and in the presence of a stream 219 National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء 2- Carbonization of The 4- Activated Carbon Oxidized Spent Lubricating Measurements: Oils A- Measurement of Density The materials from above step The density of the prepared were mixed with twice its weight of activated carbon were determined by the carbonizing agent (Ca: NaOH) and weighing 10 cm3 of the carbon sample (30-50) ml of distilled water. The using graduated cylinder(20). mixture was heated gradually with B- Determination of Ash continuous stirring till a thick bulk of Content the oxidized product were obtained. The heating was continued The ash content was measured at by heating burning one gram of the 55025C for a period of 3 hrs. The prepared activated carbon sample in a product room porcelain crucible using an electrical temperature and purified as in the next furnace for five hours at temperature of step. 1000-1100oC. the remained residue 3- Purification of The was considered as the ash content.(21) Carbonized Product C- Measurement of Humidity was cooled to The carbonized materials were One gram (exactly weighed) of crushed carefully and washed with the activated carbon was heated in an large amount of distilled water till it oven at 150oC for 3hr. The difference gives neutral test for litmus paper. The in weight before and after heating carbonized materials were mixed with operation was calculated as H2O a sufficient amount of 10% HCl vapour in the sample(22). solution. The mixture was heated D- Determination of Carbon under reflux for 1 hr, cooled, filtered Activity by Methylene Blue and washed with distilled water. The Adsorption Method washing continued till a negative litmus paper was indicated. An exactly weight (0.1 gm) of The the prepared activated carbon sample sample obtained was dried at 120C was added to an aqueous solution of 20 for 24 hr and kept for property ppm methylene blue pigment in a measurements. conical flask. The solution was shacked by an electrical shaker for 24 220 National Journal of Chemistry, 2005, Volume 18,216-225 hr at a temperature of 25oC till standardized 0.1 N iodine solution to the flask. 5- Immediately stopper flask and shake the contents vigorously for 30 minute. 6- Filter by gravity immediately after the 30 minute shaking period through filter paper. 7- Mix the filtrate in the beaker with a stirring rod and pipette 50 ml of the filtrate into 250 ml Erlenmeyer flask. adsorption of methylene blue from its aqueous solution was completed a state of equilibrium was reached. The absorbance determined of the using solution المجلد الثامن عشر-2005-المجلة القطرية للكيمياء was (UV-Visible Spectrophotometer) at max 665 nm. The procedure was carried out for the different types of the prepared samples for comparison purposes. The final concentration of methylene blue value 8- Titrate the 50 ml sample with for each activated carbon sample was standardized 0.1N sodium thiosulfate solution until the yellow color has almost disappeared. Add about 1 ml of starch solution and continue titration until the blue indicator color just disappears. Record the volume of sodium calculated as the number at milligrams of methylene blue adsorbed by one gram of carbon(23). E- Determination of Carbon Activity by Iodine Adsorption Method The iodine number (In), which is the amount (in milligrams) of iodine adsorbed from its aqueous solution by one gram of activated carbon. The method involve: 1- One gram of the dried activated carbon transferred to 250 ml Erlenmeyer flask. 2- To the flask, add 10 ml of 5% HCl and swirl until the carbon thiosulfate solution used(24). Iodine number = X m D Where: m = is the weight of the activated carbon in grams X = A – [2.2 Bx ml of thiosulfate solution used] A = N1 1269.0 B = N2 126.93 is wetted. 3- Place the flask on a hot plate, bring the contents to a boil and allow to boil for exactly 30 minute. 4- Allowing the flask and contents to cool to room temperature add 100 ml of N1 = normality of iodine solution. N2 = normality of sodium thiosulfate solution. D = correction factor. 221 National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء Production of activated carbon Lubricants resins Asphaltenes The results of using Zinc usually carried out by carbonization of Chloride for different period of times any organic compound that have high using the same feed stock showed little carbon routine effect which could be explained in carbonizing method or modified ones. term of low activity of ZnCl2 as lewis The for acid in the presence of lubricant carbonization processes is of a vital addatives. The polymerization and important to the uses and application oxidation reactions could be poisoned since activated carbon is used in the by side reactions and no increase in the removal of pollutants and support for carbon content as recognized. This catalysts, therefore in this research appeared little change of the density work liquid spent lubricating oils and adsorptive properties. Results and Discussion content choice by of a feedstock which have no economical value has On the other hand when Cobalt been used. Lubricating oils contain a Chloride substituted Zinc Chloride for large molecules and various molecular the same period of times and the same structure that may include aromatic, amount naphthenic in a free form or condense improvement and in some cases waxes is present. especially in the Iodine number and The was slight reduction in the density which conducted by direct oxidation of the may refer to a certain polymerization- material The oxidation reaction took place. The condensation process was conducted results also indicated a slight intensity by in the feed stock after treatment. carbonization till using process solidification. catalysts of different of lubricant, was a certain recognized molecular weight and ions. Application However application of Ferric of the catalysts aimed to increase the Chloride as lewis acid in the presence molecular weight (condensation and of oxygen gave a great polymerization- oxidation oxidation process which is recognized increase the oxygen functionality). Condensation by the low density and high adsorptive oxidation of for Iodine number and Methylene blue. lubricant as given by other worker may In processed throw the the following reaction addition the ability of condenseation and oxidation using (18) : different lewis acids is greatly affected 222 National Journal of Chemistry, 2005, Volume 18,216-225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء by the molecular size of the cation and the effective charge (i.e. FeCl3 > CoCl2 > ZnCl2). The results of the investigation were given in table below. Table: Properties of the Prepared Activated Carbon Sample Cat. Time Density Ash Humidity hr g/cm3 % % Iodine Methylene Number Blue mg/g Mg/g 1 - 12 0.441 1.610 0.821 150 15 2 - 24 0.440 1.521 0.800 200 19 3 - 36 0.440 1.512 0.790 225 22 4 ZnCl2 12 0.432 1.471 1.101 450 60 5 ZnCl2 24 0.431 1.521 1.001 525 63 6 ZnCl2 36 0.431 1.621 1.231 575 65 7 CoCl2 12 0.421 1.521 1.521 475 65 8 CoCl2 24 0.401 1.550 1.201 560 68 9 CoCl2 36 0.400 1.561 1.761 625 70 10 FeCl3 12 0.322 1.521 1.201 750 73 11 FeCl3 24 0.321 1.501 1.810 880 85 12 FeCl3 36 0.301 1.536 0.981 950 93 B.D.H - - 0.345 3.200 0.800 908 90 Publ. ACS, Washington D.C., USA, pp. References 1.Straughn, B., “Activated 302-309, (1984). Carbon”, Contributed by Calypso Fish & Aqyaria 3.Gracia, A., Gregorio, A., Boavida, D. and Gulyurtlu, I., “Preparation and Club, London-England, (2003). Characterization of Activated Carbon 2.O’Grady, T. M. and Wennerberg, A. Active from Pine Wastes Gasified in a Pilot Carbon”, ACS Symposium Series 303, Reactor”, Department of Inorganic N., “High-Surface Area 223 National Journal of Chemistry, 2005, Volume 18,216-225 Chemistry, University of المجلد الثامن عشر-2005-المجلة القطرية للكيمياء Coke Alicante, Spain, (2003). by Chemical Activation”, Sastech, R & D, Po. Box.1, Sasolburg 4.Ceren, K. and Meral, E., “Preparing 9570, Rep. Of South Africa, (2003). Activated Carbon from Characoal and 10.Rhamadhan, O.M., Hamdon, A.A. and Investigation of the Selective Uranium Al-Ghanam, K.A., J. Sci. & Edu., Adsorption”, Eye University Institute 2004, 16,No.2. of Nuclear Sciences, 35100, Bornova, 11.Al-Ghanam, K.A., Rhamadhan, O.M. Izmir Turkey, (2003). and Hamdon, A.A., J. Sci. & Edu., 5.Chipofya, V.H. and McConnachie, 2004, 16,No.3. G.L., “Characterization of Activated 12.Al-Ghanam, K.A., Al-Neaime, K.I. and Carbon produced from Agricultural Hamdon, A.A., J. Sci. & Edu., 2004, Waste Materials for Taste and Odour 16(3). Removal in Drinking Water Supplies”, 1st 13.ASTM Warfsa/Water Net Symposium: Method Sustainable Use of Water Resources, D2854-70, for Standard Apparent Test Density of Activated Carbon. 14.ASTM D2866-70, “Total Ash Content Maputo, 1-2 November, (2000). of Activated Carbon”, Extracts Were 6.Teng, H.S., Weng, T.C., Microporous and Mesoporous Materials, 2001, 50, Reprinted No.1, 53, Des.. Annual Book of ASTM Standard 7.Kobagashi, S., Yuan, H., Kuragane, K., Gomi, K., “Preparation of Active Carbon from Brown Coal With Permission from Copyright ASTM Race Street, (1916). 15.ISO, 5-62-1981, “Determination of and Volatile Matter Content of Hard Coal Weathered Coal with Alkali”, Chiba and Coke”, The Full Text Can be Institute of Technology: Tsudanuma, Obtained from ISO Central Secretarial Narashino-Shi Cose Postable 5G, CH-1211: Genera 20 275-0016, Japan, (2003). or from any ISO Member. 8.Aweed, K.A., “Studying the Effect of Structural Modifications on 16.Test Methods for Activated Carbon The Rasterbau Int. Engineering GMBM,W. Production of The Activated Carbon Germany Devtschos Arizeibuch 6th ed. from Heavy Crude Oil Residual by 17.AWWA Standard for Granular Chemical Treatment”, Dh. Ph. Thesis, Activated University of Mosul, (2003). Approved by J. The American Water 9.Prinsloo, F.F. and Jager, S., Carbon; B604-74, Sec. Works Association Board of Directors “Preparation of Active Carbon from on Jan. 28, (1974). 224 National Journal of Chemistry, 2005, Volume 18,216-225 18.Moschopedis, S.E. and Speight, J.G., , Fuel Science Division Alberta Canada, Journal of Materials Science, 1977, 12. 225 المجلد الثامن عشر-2005-المجلة القطرية للكيمياء