Turbulence-induced Vibration

advertisement

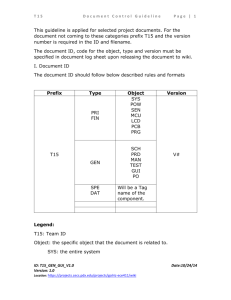

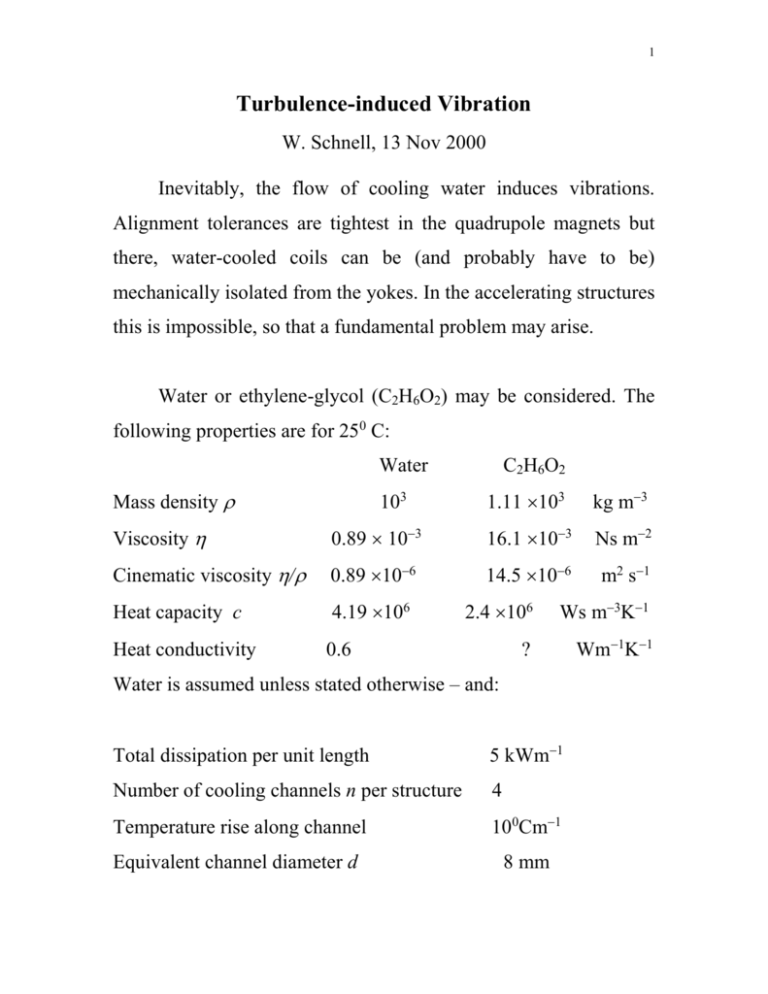

1 Turbulence-induced Vibration W. Schnell, 13 Nov 2000 Inevitably, the flow of cooling water induces vibrations. Alignment tolerances are tightest in the quadrupole magnets but there, water-cooled coils can be (and probably have to be) mechanically isolated from the yokes. In the accelerating structures this is impossible, so that a fundamental problem may arise. Water or ethylene-glycol (C2H6O2) may be considered. The following properties are for 250 C: Water Mass density 103 C2H6O2 1.11 103 kg m3 Viscosity 0.89 103 16.1 103 Ns m2 Cinematic viscosity / 0.89 106 14.5 106 m2 s1 Heat capacity c 4.19 106 Heat conductivity 0.6 2.4 106 Ws m3K1 ? Wm1K1 Water is assumed unless stated otherwise – and: Total dissipation per unit length 5 kWm1 Number of cooling channels n per structure 4 Temperature rise along channel 100Cm1 Equivalent channel diameter d 8 mm 2 Volume flow rate per channel: V/t = 3.0 10 5 m3/s = 1.8 l/min Average flow Velocity: u = 0.593 m/s Reynold’s number: Re = udr / = 5330 Moderately above turbulence limit of about 2000 Laminar flow by subdivision in small subchannels E.g. 64 subchannels of 1mm diameter in a cooling bar formed from extruded Cu strips 7 strips + 2 half-strips form 64 channels of 1mm diam. Re = 666 with water or 71 with C2H6O2 (at 5 bar/m) 0.2 m2 surface per m t = 20C for heat conduction of 1.25 kW across 0.2mm of water 3 Turbulent flow with Re 5000 Pressure drop along circular pipe of length l : p u 2 2 l d The coefficient depends weakly on Re. For smooth pipe and moderate turbulence take Blasius’ formula: = 0.316 Re1/4 or published diagrams. Result: = 0.04 Pump power = exit rate of turbulent kinetic energy: V V 2 p t t 2 ( = turbulent velocity seen from frame moving with u). Conversion of hydrostatic energy density p to turbulent kinetic energy density. Thus: 2 2 p l u2 d 4 Isotropy (marginally valid): x2 y2 z2 Local vertical (say) momentum density: yrms u l 3d Rough order-of-magnitude approximation: Nearly all energy is in coherence-cells of length d/2 thus of volume Ad/2 (with A = d2/4). Momentum per cell: rms Pycell Ad rms Ad l y u 2 2 3d Factor (2nl/d)1/2 for 2l/d such coherence-cells in length l and n cooling pipes, net momentum, therefore: rms Pytot Alu n n mu 6 6 (m = mass of water in one pipe). 5 Assume equivalent rigid mass M for struct.-cum-support, find rms. velocity transmitted to structure: rms ytot u m M n 6 Dominant frequency(): crit 2 u d Rms. vibration amplitude: s rms y 1 2 n m d 6 M (Note that 1/2 (Re)1/8). With d = 8mm thus m = 50 g/m, M = 11 kg/m (i.e. a copper rod of 40 mm diam.) and n = 4 s rms 0.94 m y crit 2 74 Hz Order of magnitude estimate! Pessimistic? 6 Order-of-magnitude considerations of turbulence spectrum by L.D. Landau, E.M. Lifschitz vol IV § 3.3: For Re/Recrit »1 the range of frequencies observed in a hardware-frame is (u/d) « « (u/d)(Re/Recrit)3/4 Within that range power spectrum 5/3 But here (Re/Recrit)3/4 2 only. So taking = 2(u/d) is not so unreasonable 7 srms (dm)/M d3/M (Re)1/8 Increase M as much as structural resonances permit. (Lowest bending mode of copper rod 0.5 m long with 40 mm diameter is at 540 Hz. The nodes are at 0.276 l ) Decrease d (i.e. increase Re) ? Not much; since crit d3 acoustic resonances will inevitably be excited for small d. Or else, very high flow velocity and crit “ above” structural resonances?? Note: l and m refer to the length of pipe of diameter d – not directly to the length of the structure. Arrange for laminar flow in input/output pipes (with tapered transitions). Conclusion: The problem is not fatal but needs experiment and careful design