22658 Uplift and discharge scrap metal

advertisement

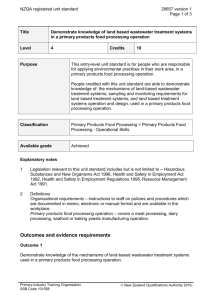

NZQA registered unit standard 22658 version 2 Page 1 of 4 Title Uplift and discharge scrap metal Level 4 Purpose Credits 6 This unit standard is for people working in the scrap metal recycling industry. People credited with this unit standard are able to: prepare to uplift scrap metal; load and secure scrap metal for transport; and discharge scrap metal at a scrap metal yard. Classification Resource Recovery > Scrap Metal Recycling Available grade Achieved Explanatory notes 1 All work practices must comply with: Carriage of Goods Act 1979; Hazardous Substances and New Organisms Act 1996; Health and Safety in Employment Act 1992; Land Transport Act 1998; Resource Management Act 1991; Heavy Motor Vehicle Regulations 1974; Traffic Regulations 1976; Land Transport Rule: Dangerous Goods 2005; Official NZ Truck Loading Code, NZTA (Truck Loading Code), available at bookshops or http://nzta.govt.nz/resources/roadcode/truck-loading-code/index.html. 2 Hazard controls, safety procedures, and personal protective equipment must be used throughout operations in accordance with company procedures. 3 Definitions Company procedures mean the documented methods for performing work activities and include health and safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. Load restraint systems are methods of securing loads to prevent load movement during deceleration in forward or rearward direction, during cornering, or while travelling over undulating roads. Usually provided by anchor points, baulking arrangements securely attached to the vehicle, or friction between the load and the load platform. Load securing devices are items used to secure loads. They include clamps, special bolts, steel wire rope, chains, webbing straps, rope, and cordage made from natural or synthetic fibres. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 22658 version 2 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Prepare to uplift scrap metal. Evidence requirements 1.1 Work instructions are confirmed in accordance with company procedures. Range 1.2 instructions include but are not limited to – location, customer details, equipment required, communication. Scrap metal to be uplifted is inspected in accordance with company procedures. Range includes but is not limited to scrap – condition, shape, size, hazards. 1.3 Loading area is checked for hazards in accordance with legislation and company procedures. 1.4 Vehicle loading is planned in accordance with company procedures. Range plan takes account of – loading and unloading locations, characteristics of the load, load handling equipment, unloading sequence. Outcome 2 Load and secure scrap metal for transport. Range loading to a vehicle for transport by road. Evidence requirements 2.1 Loading and securing of items of scrap ensures their stability during travel and is in accordance with company procedures and the Truck Loading Code. Range items – bulky, mixed small and large, mixed light and heavy, bales; includes but is not limited to – redistribution during a multiple pickup. 2.2 The scrap is loaded and stacked on the vehicle to meet legal weight and dimension requirements for transport on the road. 2.3 The scrap is loaded and secured in accordance with company procedures and load plan. Range includes but is not limited to – dangerous goods, efficient use of space. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.4 22658 version 2 Page 3 of 4 Load restraint systems are selected and used in accordance with company procedures and the Truck Loading Code. includes but is not limited to – explanation for chain selection in relation to rating and certification; use includes but is not limited to – double twitch. Range 2.5 Load securing devices are used to secure the load in accordance with company procedures and the Truck Loading Code. 2.6 The transport and delivery documentation is checked to ensure compliance with legislation in accordance with company procedures. Outcome 3 Discharge scrap metal at a scrap metal yard. Evidence requirements 3.1 Scrap metal is unloaded safely in accordance with company procedures. 3.2 Documentation relating to the delivery is completed in accordance with legislation, customer requirements, and company procedures. Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 26 January 2007 31 December 2017 Review 2 16 April 2015 N/A Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 22658 version 2 Page 4 of 4 Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016