Odor Intensity Scale - Online Abstract Submission and Invitation

advertisement

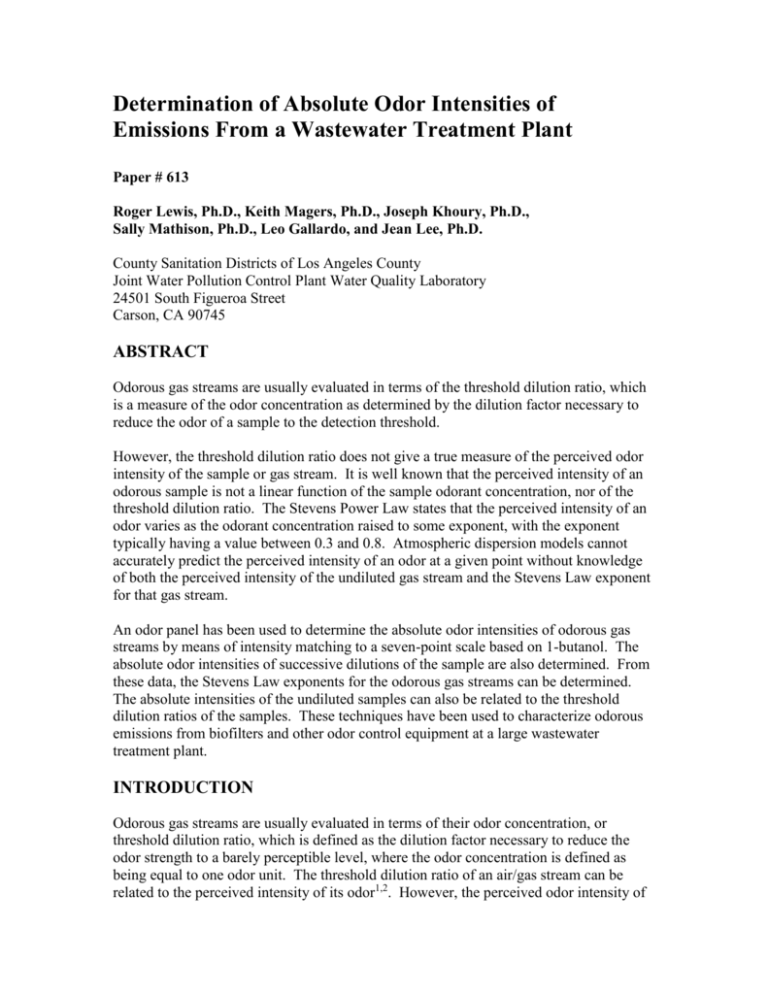

Determination of Absolute Odor Intensities of Emissions From a Wastewater Treatment Plant Paper # 613 Roger Lewis, Ph.D., Keith Magers, Ph.D., Joseph Khoury, Ph.D., Sally Mathison, Ph.D., Leo Gallardo, and Jean Lee, Ph.D. County Sanitation Districts of Los Angeles County Joint Water Pollution Control Plant Water Quality Laboratory 24501 South Figueroa Street Carson, CA 90745 ABSTRACT Odorous gas streams are usually evaluated in terms of the threshold dilution ratio, which is a measure of the odor concentration as determined by the dilution factor necessary to reduce the odor of a sample to the detection threshold. However, the threshold dilution ratio does not give a true measure of the perceived odor intensity of the sample or gas stream. It is well known that the perceived intensity of an odorous sample is not a linear function of the sample odorant concentration, nor of the threshold dilution ratio. The Stevens Power Law states that the perceived intensity of an odor varies as the odorant concentration raised to some exponent, with the exponent typically having a value between 0.3 and 0.8. Atmospheric dispersion models cannot accurately predict the perceived intensity of an odor at a given point without knowledge of both the perceived intensity of the undiluted gas stream and the Stevens Law exponent for that gas stream. An odor panel has been used to determine the absolute odor intensities of odorous gas streams by means of intensity matching to a seven-point scale based on 1-butanol. The absolute odor intensities of successive dilutions of the sample are also determined. From these data, the Stevens Law exponents for the odorous gas streams can be determined. The absolute intensities of the undiluted samples can also be related to the threshold dilution ratios of the samples. These techniques have been used to characterize odorous emissions from biofilters and other odor control equipment at a large wastewater treatment plant. INTRODUCTION Odorous gas streams are usually evaluated in terms of their odor concentration, or threshold dilution ratio, which is defined as the dilution factor necessary to reduce the odor strength to a barely perceptible level, where the odor concentration is defined as being equal to one odor unit. The threshold dilution ratio of an air/gas stream can be related to the perceived intensity of its odor1,2. However, the perceived odor intensity of an air/gas stream is not a linear function of the concentrations of the odorants present in the stream. The Stevens Power Law3 shows that the perceived intensity of an odorous sample varies as the odorant concentration raised to some power. Equation 1. Stevens Power Law I = k C where: I = the perceived odor intensity of the sample k = a proportionality constant C = the odorant concentration The exponent usually lies between 0.3 and 0.8. Atmospheric dispersion models cannot accurately predict the potential impact of odorous emissions at a downstream site without knowledge of both the perceived intensity of the undiluted gas stream and the Stevens Law exponent for that stream. The odor removal efficiencies of control equipment cannot be accurately predicted from odorous compound removal efficiencies without knowledge of this exponent. The Stevens Law exponent can be determined by measuring the perceived odor intensity of a sample as a function of the sample dilution factor or sample concentration. Conceptually, the Stevens Law exponent of any odorous air/gas stream can be measured in this manner. However, a multi-component odorant mixture may not behave in the same manner as a single component mixture, especially if the Stevens Law exponents of the various odorants in the mixture are significantly different from each other. The problem becomes more complex if the perceived odor intensities of the odorants are not additive in some simple relationship. It is likely that the intensities of odorants of the same chemical class are additive for a mixture of known concentrations, but it is unknown if odors show the same proportional additivity as the gas stream is diluted. The goal if this study, then, is to determine the concentration dependence of the perceived odor of single odorous compounds and of mixtures of these compounds. These data are used to characterize and predict the concentration dependence of odorous emissions from biofilters employed at a large wastewater treatment plant. Odor intensities were measured using an odor panel that determined the odor intensities of biofilter air streams and standard single- and multi-component mixtures of the same odorants by matching the sample intensities to those of a set of 1-butanol odor intensity standards4. EXPERIMENTAL Materials Methyl mercaptan, dimethyl sulfide (DMS) and dimethyl disulfide (DMDS) were obtained as single-component 100 ppm v/v (nominal) mixtures in nitrogen from Scott Specialty Gases. Dimethyl trisulfide (DMT3S) was obtained as the neat liquid from Aldrich. Chromatographic internal standards were obtained as a 50 ppb v/v (nominal) multi-component mixture from Scott Specialty Gases containing 1,1-difluoro-2chloroethylene, 1-fluror-2-chloroethylene, halothane, fluorobenzene, 2,3-dicloropropene, 4-fluorotoluene, 1-chloro-3-fluorobenzene, 4-fluoro-meta-xylene, and 1-bromo-4fluorobenzene. 1-butanol used to make odor standards was obtained as the neat liquid from Aldrich. UHP nitrogen (Praxair) was used as a diluent gas. GC/MS System Standards and samples were analyzed using a Leco Pegasus III time-of-flight GC/MS system. The Agilent N6890 gas chromatograph was equipped with a 60 m x 0.32 mm o.d. fused silica column (J&W DB-1, one micron film thickness). The helium carrier gas was controlled at a constant flow of 2 mL/min (nominal) by means of an electronic pressure control (EPC) system operating in the programmed pressure mode. Oven temperature program consisted of a three-minute hold at 5o C, followed by a 5o C/minute ramp to a temperature of 200oC, followed by a 40oC/minute ramp to a final temperature of 250o, where the temperature was held for three minutes. Chromatographic column effluent was routed to an open split interface (OSI, SGE Ltd.) before entering the mass spectrometer. The OSI ensured that a constant flow of effluent was introduced to the ionization region, thus eliminating response differences due to variable column flow rate. Sample introduction was effected using an Entech 7100 cryogenic preconcentrator equipped with an Entech 7032 autosampler. The preconcentrator is equipped with three cryogenically cooled traps. The first trap consists of a fused silica-lined open tube, and is cooled to approximately -20°C in order to remove water vapor from the gas sample through condensation. The second trap is filled with Tenax TA and is cooled to approximately -50°C, allowing the analytes to be trapped while allowing the permanent gases to pass through the system. In each chromatographic analysis, a fixed amount of a gaseous internal standard mixture is introduced and trapped on the Tenax adsorbent. After the internal standards and sample components have been fully loaded onto the Tenax trap, it is heated to 180°C, and the analytes are thermally desorbed and carried into the third, cryofocusing-type trap. This small, open tubular trap is cooled to -160° C and condenses the analytes in a narrow zone along its inner walls. After a four-minute transfer time, the cryofocusing trap is rapidly heated, allowing the analytes to be injected onto the chromatographic column in a tight band. Sampling Samples were taken in 6- and 15-liter fused silica-lined stainless steel canisters that were prescreened for stability with sulfur compounds. It was found that some canisters contained active sites that catalyzed the conversion of methyl mercaptan to dimethyl disulfide. Canisters were screened by introducing 150 ppb methyl mercaptan in air into the canister, then determining the actual methyl mercaptan concentration. The canister was then reanalyzed after a 24-hour holding period, and the recoveries of the two analyses were compared. Canisters with less than 90% methyl mercaptan recovery after 24 hours were deemed unsuitable for this study and were not used. Biofilter samples were taken as grab samples at the common inlet to a series of biofilters used to test various support media. Canisters were evacuated before sampling and were filled to less than atmospheric pressure (typically 0.8-0.9 atm.) to prevent water vapor condensation in the canister. Polytetrafluoroethylene (PTFE) tubing was used to connect the canisters to the sample port. The samples were pressurized with UHP nitrogen to a final pressure of approximately two atmospheres (1500 torr) and were allowed to mix for several hours before analysis or further dilution. The highest concentration samples are therefore diluted by a factor of two relative to the biofilter gas stream. Sample dilutions were carried out by transferring either a known pressure or known volume of the original sample into a second canister of known volume, then pressurizing the canister to approximately 1500 torr with UHP nitrogen. The overall dilution factors used were 2,10,50, 250 and 1000 for all samples. After dilution, the canisters were fitted with a sniffing port which consists of a length of 1/8” o.d. fused silica-lined stainless steel tubing equipped with a needle valve to control flow. The samples were presented to the odor panelists through glass nose cones affixed to the exit of the tubing. Samples were presented at a flow rate of approximately 150 mL/min, as specified by ASTM method 544-994. Certain samples were also analyzed using the ASTM E-697-91 procedure5. These samples were transferred to Tedlar bags and were analyzed promptly after transfer. Odor Intensity Standards 1-butanol odor intensity standards were made by injecting known amounts of the neat liquid through a heated stainless steel “tee” into a flowing stream of UHP nitrogen where it was swept into a 15-liter fused silica-lined stainless steel canister. The canisters were pressurized to a final pressure of about 1500 torr. The standard canisters were equipped with flow controllers (Veriflo model A202-3), which were connected to the canisters via 1/8” o.d. fused silica-lined stainless steel tubing. Each panelist sniffed the flowing standards using a glass nose cone that was placed at the exit end of the tubing. Odor standards were presented to the panelists at a flow rate of 150 mL/minute. Odor Intensity Scale A seven-step intensity scale was used in all odor intensity measurements in this work. 1butanol standards of 5.5 (level 1), 15, 40, 110, 300, 800 and 2100 ppm (level 7) were designed to increase in concentration by a factor of approximately 2.7 with each intensity level. Given that the Stevens Law exponent for 1-butanol is about 0.74, each successive standard concentration increase should result in an increase in the perceived odor intensity of about a factor of two. Level seven (2100 ppm 1-butanol) is judged to be overpowering by all panelists in this study and level one (5.5 ppm 1-butanol) was perceived as a weak odor by all panelists. The intensity scale can be described as: Equation 2. Odor intensity scale I = k’ (2n) where: I = the perceived odor intensity k = a proportionality constant n = the numerical value of the odor intensity level on the seven-point scale. METHODOLOGY For a single-component sample of known concentration, equations 1 and 2 can be combined to yield: Equation 3. k’(2n) = kC Or, in logarithmic form: Equation 4. log k” + n log 2 = log C A plot of the perceived odor intensity value n versus the logarithm of the concentration should yield a straight line of slope 3.3. This relationship can also be expressed in terms of the dilution factor Zi of a diluted sample1. Equation 5. Relationship between perceived odor intensity and sample dilution factor. Ii = k(Ci) = k(CoZi) = K(Zi) where: Ii = the perceived odor intensity of a diluted sample Ci = the concentration of the diluted sample Co = the concentration of the undiluted sample. Combining equations 2 and 5 yields (in logarithmic form): Equation 6. log K” + n log 2 = log Zi Therefore, the actual concentration of a sample need not be known in order for the Stevens Law exponent to be found. A plot of the perceived intensity value n versus the dilution factor Zi of a sample should again yield a straight line with the slope 3.3 . A sample was analyzed by determining its odor intensity at several dilution levels. Odor intensities were determined by an odor panel that matched the perceived sample intensities to the odor intensity of one of several 1-butanol standards. In a typical experiment, the panelists were asked to match the odor intensity of each sample dilution level to the odor intensity of one of the 1-butanol standards. If a panelist determined that a sample odor intensity was less than that of the lowest standard (level 1), the sample intensity was assigned a value of 0.5. Any sample found to have an overpowering intensity was assigned an intensity value of 7. If a panelist could not determine if a sample intensity was closer to one standard or another, a value midway between the two was assigned; for example, if an intensity was found to be greater than that of the level 3 standard, but less than that of the level 4 standard, it was assigned a value of 3.5. The mean value of the panelists’ responses to each sample dilution level was used as the perceived odor intensity at each dilution level. After the odor intensities of each sample dilution were determined, each dilution level was analyzed by GC/MS to determine the concentrations of the odorants in the sample. RESULTS Samples were taken during the months of October and November 2004 from the common inlet of a series of biofilters. It was found that almost all of the significant odorants were sulfur compounds. Four sulfur compounds were found in all samples: methyl mercaptan (MeSH), dimethyl sulfide (DMS), dimethyl disulfide (DMDS) and dimethyl trisulfide (DMTS). In a few samples, iso-propyl mercaptan and tert-butyl mercaptan were also observed at very low concentrations. The sulfur gas concentrations determined for the undiluted samples are listed in Table 1. In most samples methyl mercaptan was the dominant odorant and was typically found at a concentration of two to five times higher than dimethyl sulfide and five to ten times higher than dimethyl disulfide. Dimethyl trisufide was found at concentrations less than 10 ppb in all samples. Also shown in Table 1 are data for synthetic mixtures of the four sulfur odorants. These samples were prepared to approximate the odorant concentrations observed in biofilter samples. As expected, the slopes, intercepts and values are similar to those of the biofilter samples. Table 1. Sulfur Gas Odorant Concentrations (ppb v/v) Date 14-Oct 22-Oct 26-Oct 29-Oct 2-Nov 5-Nov 9-Nov 12-Nov 16-Nov Type MeSH Biof inlet 500 Biof inlet 840 Biof inlet 14 Biof inlet 0 Biof inlet 107 Mix 11/02(a) 130 Mix 10/22(b) 750 Biof inlet 690 11/12 repeat 690 DMS 380 480 5 325 24 22 410 280 280 DMDS 310 45 1 30 20 13 170 80 80 iso-PrSH tert-BuSH DMTS 5 2.5 <0.2 5 2 3 4 4 9 2 5 2 5 (a) Synthetic mixture equivalent to November 02 sample (b) Synthetic mixture equivalent to October 22 sample Odor intensity data are shown in Table 2. The intensities listed are the mean numerical intensity levels calculated from the responses of the odor panelists. A typical plot of perceived odor intensity versus dilution factor is shown in Figure 1. Sample dilution factors ranged from 2 to 1000. In most cases, the highest dilution factors resulted in an odor barely perceivable by the panel while the other dilution steps were chosen to result in measurable differences in the odor intensities of the samples. In general, the odor intensity plots have slopes lying between 1.5 and 2.0, which result in values between 0.45 and 0.61. Linearity is good in most plots, although the lowest level point (highest dilution factor) may reflect the canister background odor in some cases. The observed slopes, intercepts and values of the individual plots are shown in Table 2. Figure 1: Intensity vs. Log Z 10/29 5 4.5 y = 1.6781x + 5.8512 R2 = 0.9811 4 3.5 Intensity 3 2.5 2 1.5 1 0.5 0 -4 -3 -2 Log Z -1 0 The odor intensities as a function of concentration were also determined for each of the four main sulfur odorants. Methyl mercaptan, dimethyl disulfide and dimethyl disulfide odor intensities were measured over the concentration range of 1 ppm to 1 ppb, and dimethyl trisulfide odor intensities were determined over the range of 0.1 ppb to 10 ppb. At the highest concentration studied, methyl mercaptan typically had an odor intensity equivalent to approximately 300 ppm 1-butanol (level 5), 1 ppm DMS was equivalent to approximately 110 ppm 1-butanol (level 4), and DMDS was equivalent to about 40 ppm 1-butanol (level 3). DMTS was found to be a much stronger odorant than the others, and had an odor intensity of approximately level 5 (300 ppm 1-butanol) at a concentration of 10 ppb—a concentration 100-fold lower than the concentration of methyl mercaptan with the same odor intensity. The Stevens Law exponents derived from these studies range from about 0.44 (DMTS), 0.40 (MeSH and DMS) to about 0.23 (DMDS). The plots are shown in Figures 2a-d. There is a significant amount of scatter in the plots and it is seen that the average odor intensity determined for a given concentration evaluated on different days can be subject to large variations. There may or may not be a significant difference in the slopes of the MeSH, DMS and DMTS plots, but the slope found for DMDS does appear to be significantly lower than that of the others. Table 2. Observed Odor Intensities and Values. Date Type 14-Oct 22-Oct 26-Oct 29-Oct 2-Nov 5-Nov 9-Nov 12-Nov 16-Nov 2 Biof inlet 5.21 Biof inlet 6.25 Biof inlet 3.56(c) Biof inlet 4.43 Biof inlet 4.06 Mix 11/02(a) 5.3 Mix 10/22(b) 5.57 Biof inlet 5.13 11/12 repeat 5.17 10 3.5 5 3 2.85 3.125 4 4.21 3.5 3.08 Dilution Factor 50 250 2.07 1.07 3 1.5 2.13 0.87 1.64 1 1.81 0.813 2.4 1.7 3 2.07 2.38 1.63 2.17 1 slope I(o) 1.98 2.16 1.66 1.68 1.58 1.58 1.72 1.6 1.63 5.6 6.9 4.88 5.85 4.59 5.55 6.02 5.34 5.16 0.60 0.65 0.50 0.51 0.48 0.48 0.52 0.48 0.49 1000 0.67 0.563 1.1 0.79 0.63 0.7 (a) Synthetic mixture equivalent to November 02 sample. (b) Synthetic mixture equivalent to October 22 sample. (c) Dilution factor of 8. DISCUSSION The odor intensity plots for the four target odorants appear to be reasonable. The high concentration (1 ppm) odor intensities are determined with reasonable accuracy and the slopes are within the range of values expected for the Stevens Power Law. Odor detection thresholds can be calculated by extrapolating the observed lines to level zero (no odor present). The extrapolated detection threshold concentrations are in reasonable agreement with values reported for MeSH, DMS and DMTS, but the extrapolated threshold concentration for DMDS is significantly lower than reported elsewhere6,7. This implies that the concentration dependence of DMDS odor intensity is somewhat stronger than observed here. Figure 2b: Dimethyl Sulfide 6 6 5 5 4 4 Intensity Intensity Figure 2a: Methyl Mercaptan 3 2 y = 1.3357x + 0.9382 R2 = 0.7397 1 y = 1.3426x - 0.0227 R2 = 0.609 3 2 1 0 0 0 1 2 3 4 0 1 Log C 3 4 Log C Figure 2c: Dimethyl Disulfide Figure 2d: Dimethyl Trisulfide 6 6 5 5 y = 0.751x + 0.7546 R2 = 0.6572 4 Intensity Intensity 2 3 2 1 y = 1.4599x + 3.1143 R2 = 0.9871 4 3 2 1 0 0 0 1 2 Log C 3 4 -3 -2 -1 0 Log C 1 2 The slopes and Stevens Law values shown in Table 2 are higher than the slopes and values for the individual components of the mixtures. This infers that there is some degree of odor additivity in the odorant mixtures. Due to the varying concentrations of the odorants, however, the contributions of the individual odorants to the overall intensity behavior are not weighted equally. The concentration dependence of the odor intensity of a mixture will necessarily reflect the behavior of the most intense odorants. If odor intensities of the individual components of a mixture are calculated from the observed intensity versus concentration functions and then summed, the contribution of each odorant to the total odor intensity of the sample can be estimated. In these samples, methyl mercaptan and dimethyl trislfide are the major contributors to the odor (40% and 35%, respectively) while dimethyl sulfide and dimethyl disulfide are lesser contributors (15% and 10%, respectively). It is likely that the odor concentration dependence will be driven by the concentration dependence of the major odorants. If the total sample odor intensity is calculated from the intensity versus concentration functions and it is assumed that the odorant intensities obey simple arithmetic additivity, the concentration dependence of the odor intensity may be calculated. In all samples evaluated in this work, the calculated concentration dependence has a much lower slope than is observed experimentally. The calculated slopes and intercepts are compared with the observed values in Table 3. Table 3. Comparison of Measured and Calculated Odor Intensities and Values Date 14-Oct 22-Oct 26-Oct 29-Oct 2-Nov 5-Nov 9-Nov 12-Nov 16-Nov Type Biof inlet Biof inlet Biof inlet Biof inlet Biof inlet Mix 11/02(a) Mix 10/22(b) Biof inlet 11/12 repeat slope 1.98 2.16 1.66 1.68 1.58 1.58 1.72 1.60 1.63 I(o) 5.6 6.9 4.88 5.85 4.59 5.55 6.02 5.34 5.16 0.60 0.65 0.50 0.51 0.48 0.48 0.52 0.48 0.49 I(o) Calc 4.87 6.23 6.42 5.59 5.78 5.52 5.54 6.30 Calc 0.37 0.38 0.39 0.40 0.38 0.39 0.39 0.39 (a) Synthetic mixture equivalent to November 02 sample. (b) Synthetic mixture equivalent to October 22 sample. There are several possible causes of this behavior. If the measured value for methyl mercaptan (the major odorant) is lower than the true value, calculated slopes would be lower than expected. The experimentally observed slopes can be replicated if a value of about 0.58 (corresponding to a intensity versus concentration plot with a slope of 1.9) is used. While use of this value will result in a line with a slope matching the observed slope, the predicted odor intensities of the undiluted samples exceed the observed intensities by one to two levels. Alternatively, if the observed odor intensity of approximately level 5 at 1 ppm methyl mercaptan is used to anchor the intensity function while keeping a value of 0.58, the predicted detection threshold for methyl mercaptan is much too high. The experimentally observed slope can also be replicated by increasing the slopes of all intensity functions by about 23%; however this also results in calculated undiluted intensities much higher than those observed. It is unlikely that there is another undetected odorant present that has a significant odor intensity and higher value that could serve to increase the slope. Synthetic mixtures of the odorants--which clearly cannot contain unknown odorants--also exhibit calculated slopes that are much lower than those observed experimentally. The most likely explanation for the difference, then, is that the odors do not exhibit simple arithmetic additivity. A more complex additive relationship exists which results in the odor intensity decreasing at a much faster rate than predicted as the mixture is diluted. It is also possible that a lower intensity odorant masks the intensity of the principal odorants in a manner that results in a faster intensity drop off. The existing data do not allow any conclusions to be drawn as to the exact reason for the discrepancy between observed and calculated odor intensity behavior. The existing data for samples containing methyl mercaptan as the principal odorant show an average Stevens Law value of about 0.53. Any odor control strategy must necessarily require any odorant removal device to operate at very high efficiency if significant odor removal is to be achieved. For example, a ten-fold reduction in odor intensity (90% odor removal efficiency) would require 98.7% odorant removal efficiency. An odorant removal efficiency of 75% would result in a barely perceptible odor intensity decrease of a factor of two. The relatively low Stevens Law exponents found for the individual compounds suggest that gas streams containing a single odorant such as methyl mercaptan must have extremely high removal efficiencies to achieve high odor removal efficiencies. A gas stream containing methyl mercaptan only would require an odorant removal efficiency of 99.6% in order to achieve 90% odor removal. A methyl mercaptan removal efficiency of 88% would be required to reduce the odor intensity by a barely perceptible factor of two. ACKNOWEDGEMENTS Enlightening discussions with the JWPCP Engineering Research staff are gratefully acknowledged. REFERENCES 1. Chen, Y., Bundy, D.S. and Hoff, S.J., Using Olfactometry to Measure Intensity and Threshold Dilution Ratio for Evaluating Swine Odor, JAWMA, 49 (7) 847853. 2. Chen, Y., Bundy, D.S. and Hoff, S.J., Development of the Relationship between Odor Intensity and Threshold Dilution Ratio for Swine Units, JAWMA, 49 (9), 1082-1088. 3. Stevens, S. S., The Psychophysics of Sensory Function, Am. Sci., 48, 226-253 (1960) 4. ASTM, Standard Practices for Referencing Suprathreshold Odor Intensity, E-544-99, 1999. Annual Book of Standards, 1999. Amer. Soc. For Testing and Materials, Philadelphia, Pa. 5. ASTM , Standard Practice for Determination of Odor and Taste Thresholds By a Forced-Choice Ascending Concentration Series Method of Limits, E-679-91, 1991. Annual Book of Standards, 1991. Amer. Soc. For Testing and Materials, Philadelphia, Pa. 6. Nagata, Y., Measurement of Odor Threshold by Triangle Bag Method, Proceedings of the International Symposium on Odor Measurement, Tokyo, Japan (2003) 7. Verschueren, K. Handbook of Environmental Data on Organic Chemicals, Van Nostrand Rienhold, New York (1983)