- the Journal of Information, Knowledge and Research in

advertisement

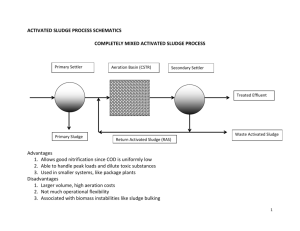

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN CIVIL ENGINEERING HIGH PURITY OXYGEN ACTIVATED SLUDGE PROCESS FOR TREATING EFFLUENT:- OPEN TO ATMOSPHERE SYSTEM 1ASHISH 1 GULABANI, 2 DR. PROF. N.S. VARANDANI. Student of M.E. 4th Semester Environmental Engg. Dept. L.D. College of Engineering 2 Head of the Environmental Engg. Dept. L.D. College of Engineering. 1 ashuchem87@gmail.com ABSTRACT : There are many of the problems of wastewater treatment – in both municipal and industrial wastewater treatment plants – are the result of insufficient oxygen. The consequences are inadequate purification or even anaerobic decomposition processes, giving rise to highly offensive odors. The systematic input of pure oxygen at critical points along the wastewater chain solves these problems quickly, flexibly and efficiently. Many activated sludge plants built years ago are no longer able to handle today’s increased requirements concerning waste water purification. Because of greater pollutant loads, the installed aeration systems are unable to supply the micro-organisms with enough oxygen. This is an attempt to throw some options to handle the increasing load of the pollutant in the wastewater treatment for existing activated sludge process for the wastewater treatment with the help of pure oxygen. 1. INTRODUCTION High purity activated sludge process is not the new technology, it is the existing one, But not widely applicable due to higher operating cost and maintenance cost and also with the main requirement of the completely closed system to recycle of the oxygen and to utilize the maximum amount of oxygen in the process rather then wasting it in atmosphere. Now, our efforts to make this process technically and economically viable for the conventional activated sludge process i.e. open to atmosphere system, for that idea is to increase the concentration of oxygen in the supply of air as all are aware that in the atmosphere approximate 20% of oxygen is available so to increase that concentration from 20%, & up to 60-70 % depends on the dissolve rate requirement with keeping in mind that minimum amount of oxygen is wasted in the atmosphere. There is literature available for the pure oxygen system, keeping those advantages and disadvantages in mind this study has been carried out. Listing out the advantages and disadvantages of the High purity oxygen activated sludge process for giving an overview of the future need & scope for the study. Problems that can arise in waste water treatment plants: 1. Lack of oxygen in existing activated sludge plants, as a result of: Increased waste water inflow Increased concentration of pollutants Greatly fluctuating pollutant load More thorough purification dictated by stricter legal requirements 2. Failure of aeration systems, caused by: Defective compressors for diffused aeration Damage to mechanical surface aerators 3. Inadequate elimination of nitrogen. Should the existing aeration system be enlarged? To increase the aeration capacity in overloaded activated sludge tanks, there is usually no choice but to enlarge the aeration equipment – a costly undertaking. It may be necessary, for example, to install larger surface aerators, additional compressors, as well as air diffusers. But such measures quickly run up against the following constraints: The space requirement is too great; the activated sludge tank is too small to accommodate any more equipment. Uneconomical and inefficient oxygen transfer, due to injection of too much air at points crowded too closely together. And because the aeration facility must be designed from the outset to cope with the maximum load, high investment costs are involved. Advantages of Using Pure Oxygen Low investment costs Quick and economic solutions to problems Focused injection of oxygen Increased efficiency without enlarging facilities Low maintenance requirement Optimum oxygen utilization Flexible oxygen injection High oxygen concentrations attainable ISSN: 0975 – 6744| NOV 10 TO OCT 11 | Volume 1, Issue 2 Page 56 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN CIVIL ENGINEERING II. Aim “To increase the in situ capacity of activated sludge process by doing study on pilot scale by introducing the pure oxygen and with the ultimate goal of the study is to make smaller footprint” III. Future Needs & scope of Study: One line sentence for understanding the needs & scope “Smaller Footprint” Needs & Scope As per current scenario for an available land & the continually increasing cost in construction sector. It is hard to invest a corers of rupees for an effluent treatment, and also the governing factor for this study is increased use of water against the “Scarcity of Water” & stringent rules & regulation by the government, it has become necessity for an industries to reuse or recycle or to control the quality of an effluent generated form premises. Seeing above needs if this study outcomes with a positive results then it will be helpful in many industries for increasing the treatment capacity & load on a present ETP & to serve the other objectives. iv. The process: activated sludge process literature A basic activated sludge process consists of several interrelated components: An aeration tank where the biological reactions occur An aeration source that provides oxygen and mixing A tank, known as the clarifier, where the solids settle and are separated from treated wastewater A means of collecting the solids either to return them to the aeration tank, (return activated sludge [RAS]), or to remove them from the process (waste activated sludge [WAS]). Aerobic bacteria thrive as they travel through the aeration tank. They multiply rapidly with sufficient food and oxygen. By the time the waste reaches the end of the tank (between four to eight hours), the bacteria has used most of the organic matter to produce new cells. Various types of Activated sludge processes. The organisms settle to the bottom of the clarifier tank, separating from the clearer water. This sludge is pumped back to the aeration tank where it is mixed with the incoming wastewater or removed from the system as excess, a process called wasting. The relatively clear liquid above the sludge, the supernatant, is sent on for further treatment as required. Various types of ASP. 1. Completely mixed activated sludge process. 2. Conventional dispersed plug flow activated sludge process 3. Contact stabilization activated sludge 4. High purity oxygen activated sludge 5. Oxidation ditch (extended aeration) activated sludge process 6. Sequencing batch reactor (SBR) activated sludge process 7. Microfilter membrane bioreactor (MMBR) High purity oxygen activated sludge Process Advantages Five times oxygen transfer rate over air Smaller volume Higher MLSS concentration possible, but limited by secondary settler capacity Disadvantages ISSN: 0975 – 6744| NOV 10 TO OCT 11 | Volume 1, Issue 2 Page 57 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN CIVIL ENGINEERING Very expensive: covered tanks, high energy cost for O2 generation, gas recirculation equipment Headspace CO2 accumulation and associated pH drop requires alkalinity addition No flexibility (all aerobic processes) Nitrification is problematic – low pH, short HRT produces high biomass at short SRT Settling problems have been reported Alternative options for oxygen supply & their comparisons. Cryogenic Distillation Performance Comparisons (% Purity) Power Needs (KWh/Ton O2) control the cost of generation of oxygen, but mainly concentrating the above three for the supply option for oxygen. So comparing the above three technologies. V. Details of the pilot study Scale selected Pilot scale: i.e Combination of theoretical scale study & with Oxygen cylinder as a source of pure oxygen on pilot scale. Place: - Pilot scale study at Effluent Treatment Plant ARVIND LIMITED, SANTEJ (A Textile Industry) Ion Transport Membrane Pressure swing (ITM) Adsorption (PSA) + 99.99% 99 % 85-94% 259 162 36 Operating Temperature (In ˚C) Low 800-900 Ambient Operating Pressure Maximum is 13,000 kPa Maximum is 7,000 kPa Maximum is 150 kPa FCI (For 1 MTPD O2) in Rs. Approx 11.1 Approx 7.5 Approx <<5 Lacs Operating Cost in Rs. / MT O2 Production Approx 120 Approx 88 Approx 10 Per DAY Basis There are two possible ways for supplying the additional oxygen 1) Oxygen cylinder or other outside source or 2) On site oxygen generator units Oxygen cylinders or other outside source Oxygen cylinders are the good option for the small scale unit where the requirement of oxygen is less as compare to large scale unit. While seeing the large scale requirement it is not suggested to use the oxygen cylinder. The other factor considering the safety involved in the operating plant with oxygen cylinder and the main factor to be consider is the availability of an oxygen cylinder from any near by place or city with minimum transportation cost which leads to saving an fixed capital investment in the operation So this option of supplying the oxygen is only advisable if the company is small scale unit. On site oxygen generator units Alternative technologies for onsite oxygen generation Unit Cryogenic Distillation Ion Transport Membrane (ITM) Pressure swing Adsorption (PSA) And there are more technologies available and also some modifications done in the above technologies to (Photograph showing pilot scale plant at site.) Details of the Pilot Plant at initial level of study: Flow : 65-70 m3/Day Tank Size (m) : 4.5 x 4.5 x 2.5 I/L COD : 550 ppm Avg. I/L BOD : 250 ppm O/L COD (to achieve) : 80 ppm O/L BOD (to achieve) : 10 ppm MLSS concentration : 2000 MLVSS concentration : 1550 ppm DO : 2.5 ppm pH : 7.65 HRT (present) : 18-20 hrs ISSN: 0975 – 6744| NOV 10 TO OCT 11 | Volume 1, Issue 2 Page 58 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN CIVIL ENGINEERING For observing the effect due to the following variable parameters on the aerobic treatment Variable parameters: Flow m3/Day : 80, 90, 100, 120 MLSS ppm : 2000, 2500, 2800, 3000 Observations to be done Air requirement Power Consumption HRT Result MLSS : 2500 ppm DO : 2.5 ppm O/L COD : 90-120 ppm O/L BOD : 10-25 ppm HRT : 16 Hrs Result MLSS : 3000 ppm DO : 2.5 ppm O/L COD : 60-120 ppm O/L BOD : 10-25 ppm HRT : 15 Hrs Overall Result in Percentage improvement : 15-20 % vi. Result & Discussions [5] http://www.icheme.org/literature/conference s/gasi/Gasification%20Conf%20Papers/Session%204 %20presentation-Allam%20et%20al.pdf (comparison of alternatives) [6] http://www.psaplants.com/psa-gasplants.html [7] http://www.industrialgasplants.com/pressure -swing-adsorption.html [8] http://www.lindeindia.com/userfiles/image/File/O2%20Plants/Oxygen %20Generatation%20by%20PSA.pdf The above results shows that with the study it has successfully improved in capacity with the increase in the HRT in the sense that one can handle more effluent in the effluent treatment plant in that extra saved time and it is observed to be savings in power consumption also which is found to be half of the existing value. CONCLUSION After doing this study, It is found that it is technically possible to apply the High purity Activated Sludge process in the open to air system. The power cost calculation is done & it is found to be very cheap & almost 50% less compare to existing scenario but it involves higher capital investment at the initial level which has a payback period of approx 5 yrs. Post maintenance will be another problem cause it requires highly skilled person to get involved at the process which makes the process more costly So, for a small scale industry which has very low effluent load are not advisable to go for this process while for larger scale unit it still required to think before going for this process cause of post maintenance cost. REFERENCES [1] S B Thakore B I Bhatt.(2007), Introduction to Process Engineering and Design; TATA MCGRAW-HILL; [2] Ruthven, D., Farooq, S. and Knaebel, K. (1993); Pressure Swing Adsorption; VCH NewYork; [3] Metcalf & Eddy, Inc. (2003). Wastewater Engineering: Treatment and Reuse, 4th edition, McGraw Hill, Inc.; [4] http://www.mvsengg.com/products/psaoxyg en/ (Cost of Production of O2 ) ISSN: 0975 – 6744| NOV 10 TO OCT 11 | Volume 1, Issue 2 Page 59