Siphonic Roof Drainage Association

advertisement

bYTEBoss

Online document search engine; Microsoft Word, Excel,

Powerpoint

Home

Upload

Report abuse

Contact

Search

PDF DOC XLS RTF PPT All

Siphonic Drainage Specificationr 1.02

Open document | View with Google Docs | Download document | Copyright abuse

Content preview

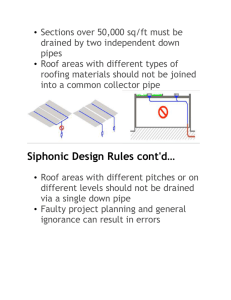

SPECIFICATION FOR SIPHONIC ROOF DRAINAGE SYSTEMS . . SIPHONIC SYSTEMS,

GUTTERS AND PIPEWORK TO THE REQUIREMENTS OF BS 8490:2007. . . 1R10/.

SCOPE OF WORKS:. . -. Drawing ref: {}. . Description: {}. . R10/22. SIPHONIC ROOF

DRAINAGE SYSTEMS TO BS8490:2007. . -. Drawing references: {}. . -. Manufacturer: To be

tendered (Must be a member of the Siphonic Roof Drainage Association). . -. The system must

be designed within the following parameters to operate on siphonic principles so as to be

regularly self-cleansing in normal use.. . -. Pipework must remain airtight at maximum and

minimum operating pressures. . Pipework and fittings: High Density PolyEthylene to DIN

8074/8075/16963 or BS EN 1519.. HDPE Pipework must be SDR 26 regardless of grade of

HDPE. (for pipework to be used in systems with a maximum negative pressure of 4.5m, PN 3.2

pipework with lower SDR ration can be used.). Alternative/Supplementary pipe materials {

Delete if not to be used}. Cast Iron to BSEN877. Stainless Steel to BSEN1124. Galvanized steel

pipe to EN 1123. . -. Pipework must accommodate thermal movement by using a rigid fixing

system (see manufactures literature for details). Pipework shall be transversely braced at

maximum 15m to prevent pipework sway.. . -. Design rate of rainfall for siphonic system: {

Enter RI } l/(s.m2)*. *(As BSEN12056, Appendix NB, {Enter building life and factor of

safety}).. -. The gravity underground drainage system must be designed to accommodate the

maximum peak flow from the siphonic system, or allow excess water to discharge from open

manhole covers with no back up pressure to the siphonic system. Maximum available capacity of

below ground drainage in litres/second: {}. Maximum design water depth during design rainfall

of 2 minutes duration: To be designed to keep water depth on roof to acceptable limits. Overflow

arrangements: Each roof area to be fitted with at least one emergency overflow pipe discharging

in a conspicuous location outside the building . Minimum siphonic flow velocity: 1.0 m/second..

. -. Maximum pressure imbalance between outlets: 1m. . -. Minimum operational pressure: 8.8m

vacuum for HDPE pipework, 7.8m vacuum for all other materials.. . -. System fill time (priming

time) must be determined in accordance with BS 8490:2007. Calculations must be undertaken

using software accredited by a third party, showing velocities, pressure values and sizes of each

component and fitting. The system should be balanced such that any residual head at any of the

outlets is as a maximum -0m/+1m. (ie the outlet is able to take slightly too much water). Gutter

designs should be carried out to the requirements of BSEN12056-3:2000, using water depths at

the outlet based on third party accredited physical test data.. Butt jointing of pipework on site is

prohibited, unless this takes place at ground level, using a hydraulically operated butt fusion

machine.. . . INSTALLATION. . 3. R10/555. BEFORE COMMENCING WORK specified in

this section, it must be ensured that:. . -. Below ground drainage is ready to receive rainwater or

that the discharge can be dispersed by approved means to prevent damage or disfigurement of

the building fabric.. . . 4. R10/66666. INSTALLATION GENERALLY:. The installation should

avoid all existing services. The contractor will be responsible for carrying out a survey of

conflicting services and roof area/gutter before detailed design commences.. . -. Install

pipework/outlets to ensure the complete discharge of rainwater from the building without

leaking.. . -. Avoid contact between dissimilar metals and other materials, which would result in

electrolytic corrosion.. . -. Adequately protect pipework/gutters from damage and distortion

during construction. Fit purpose made temporary caps to prevent ingress of debris. Fit all access

covers, cleaning eyes and blanking plates as the work proceeds.. . -. Where not specified

otherwise use plated, sherardized, galvanized or nonferrous fastenings, suitable for the purpose

and background, and compatible with the material being fixed.. . 5R10/55. BUILDERS WORK:

Comply with restrictions on the cutting of holes, chases, notches, etc. and methods of attachment

to the building fabric specified in local or national guidelines.. . 6. RAINWATER OUTLETS:

Ensure that:. . -. Outlets are securely fixed before connecting pipework.. . -. Junctions between

outlets and pipework can accommodate all movement in the structure and pipework.. .

7R10/88888888888887. SIPHONIC DRAINAGE PIPEWORK:. . -. Fix pipework neatly,

securely and adequately to prevent movement during extreme operating conditions including

oscillating pressure and vibration.. . -. Fix pipes with the specified number of joints, bends and

offsets, exactly in accordance with the manufacturers drawings.. . -. All pipework is to be fully

accessible for repair or replacement unless specified or shown otherwise.. . -. Provide additional

supports as necessary to support junctions and changes in direction.. . -. Completed pipelines to

be of smooth, consistent bore, clean and free from distortion, wrinkling, cracks and other

defects.. . 8. R10/1010. COATED PIPEWORK/GUTTERS: Make good to coatings after cutting

and any other damage or re-coat, as recommended by the manufacturer.. . 9. R10/20.

IDENTIFICATION OF INTERNAL RAINWATER PIPEWORK: To BS 1710 using selfadhesive bands or identification clips located at junctions, at both sides of each slab, bulkhead

and wall penetration, and elsewhere as directed.. . R10/10. TESTING GENERALLY:. . -. Inform

CA sufficiently in advance to give him a reasonable opportunity to observe tests.. . -. Check that

all sections of installation are free from obstruction and debris before testing.. . -. Provide clean

water, assistance and apparatus for testing as required.. . -. Carry out tests as specified. After

testing, locate and remedy all defects without delay and retest as instructed.. . -. Keep a record of

all tests and provide a copy of each to the CA.. . 11. R10/13. INTERNAL PIPEWORK TEST:. .

-. Temporarily seal open ends of pipework with plugs.. . -. Connect a U tube water gauge and air

pump via a plug.. . -. Pump air into pipework until gauge registers 38 mm.. . -. Allow a period for

temperature stabilization, after which the pressure of 38 mm is to be maintained without loss for

not less than 5 minutes.. . R10/12. GUTTER TEST: Block all outlets, fill gutters to overflow

level and after 5 minutes closely inspect for leakage.. . R10/13. IMMEDIATELY BEFORE

HANDOVER:. . -. Remove construction rubbish and debris from all roofs and gutters. Where

possible, sweep and remove fine dust, which may enter rainwater systems. Do not sweep or flush

dust or debris into the rainwater system.. . -. Remove swarf, debris and temporary caps from the

entire rainwater installation.. . -. Ensure that all access covers, outlet gratings, etc. are secured

complete with all fixings.. . . . . .

Search Wikipedia for Siphonic Drainage Specificationr-1.02

Search Bing for Siphonic Drainage Specificationr-1.02

Search Google for Siphonic Drainage Specificationr-1.02

Latest files

Facilities Inspection Services Eastbay.pdf

Facilities Inspection Services East Bay

Aluminum Scaffold Bay Area.pdf

Scaffolding Company, Aluminum Scaffold Bay Area

Solar Farm Developers.pdf

Solar Farm Developers

Biotechnology Company San Francisco Bay Area.pdf

Newomics BioTechnology Company San Francisco Bay Area

Italfood Water Guide.pdf

Importer & Wholesalers of Selected of Foreign and Domestic Food

Products

Deck Refinishing Walnutcreek.pdf

AllproDeck,complete resource for Deck Refinishing, Interior and

Exterior Painting, Deck Restoration, Power Washing in Walnut

Creek,California.

Light Duty Towing Roadside Assistance.pdf

Action Towing & Road Service complete resource for Heavy &

Medium Duty Towing, Light Duty Towing in California.

Chocolate Ptca Balloon Catheter.pdf

QTVascular,Innovative in Minimally Invasive Treatment for

Vascular Disease Treatment product includes Balloon Catheters.

Centrifugal Pumps Reliability.pdf

Price Pump,Pump Manufacturer in California complete resource for

Magnetically Driven Centrifugal Pumps, Close Coupled Centrifugal

Pumps, Vertical Centrifugal Pumps, Air Operated Diaphragm(AOD)

Pumps.

Executive Search Firms San Francisco Bay Area.pdf

Hager Executive Search,complete resource for Executive Search

Firms in San Francisco Bay Area.

Website thumbnail

Thumbnail provided by www.webthumbnail.com

Recommended

OrderForm2012Winter

o 5.95. 8.9499999999999993. 0. 0.5. 1. 0. 5.95. 8.9

o 50386edecb613 Cv

CHERIE BELL HAZEL E. CENTENOAddress: 074 Palagay

52459022273f1root Words B And C

Root WordsBiblo (G)Definition - bookExamples:Bibl

Social Sciences 9 13

GIVEN THESE OVERALL SIMILARITIES, THEN,

WHAT DIST

246594statement Of Discovery Issues Blue Mountain 8 26

2013

Mary Anne Q. Wood (3539)Stephen Q. Wood

(12403)Wo

Contact List Risocas

Sheet3. Sheet2. Sheet1. Name. Nationality.

Organi

Catalogue Can Aud 2012 10 12

Sheet3. Sheet2. Sheet1. 978 1 4079

3368 9. ANDREW

Nr13 Worldblu

CONTACTDyle

StoddardCreative

Directordyles@greath

9261cenik Vbv Voc 1.9.2013

2012. 0.75.

71.069999999999993.

86. 170. 2012. 0.

Cdp Web5c

Johnw.hardeewritesed

itoropenletteronkkk

o Tabor City

Tribune 8-950. . John W.

Hardee Write

o 2308 Grades

Sp 11

by

tua123

45.

2308

grades

Src

SP11.

possibl

e pts:

electro

negativ

itefr

M

u

n

k

a

3

.

M

u

n

k

a

2

.

M

u

n

k

a

1

.

Z

.

A

l

l

r

e

d

R

o

c

h

o

w

.

1

.

0

0

.

2

H

u

n

g

e

r

H

o

w

d

o

e

s

m

o

t

i

v

a

t

i

o

n

d

i

r

e

c

t

a

n

d

e

n

e

r

g

i

z

e

b

e

h

a

v

i

o

r

?

L

a

C

e

l

e

s

t

i

n

a

2

No thanks