Learning to live off the land, Martian style

advertisement

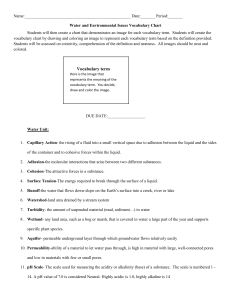

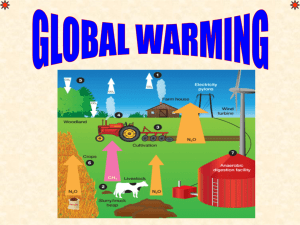

Learning to live off the land, Martian style By Vivian Cooper-Capps October 26, 2001 Boasting the largest volcano in the solar system, the deepest canyon, the wildest sand storms and two moons, Mars promises to be the ultimate extreme vacation spot in the solar system. When the first astronauts touch down on the Red Planet, however, they will be too busy to do much sightseeing. In addition to their normal exploration activities, they will be living off the land. According to current mission designs, one of their first priorities will be to set up and begin running several mini-factories that are designed to extract enough oxygen and water for life support from Mars materials, produce building material for shelters from Martian rock and manufacture enough fuel and consumables for the nine-month return voyage to Earth. The National Aeronautics and Space Administration is mounting a series of unmanned missions to Mars, including the Mars Odyssey Orbiter that swung into orbit around the Red Planet on October 24th. Currently, the U.S. space agency does not have any specific plans for a manned mission to Mars. However, it is supporting a number of smaller studies that address the problems that must be solved to make such a mission possible. Among these are two research projects at Vanderbilt that are developing systems that can produce oxygen, fuel and building materials out of basic Martian materials. Oxygen and water are abundant on Earth, but that is not the case on Mars. The Martian atmosphere consists almost entirely of carbon dioxide and contains only trace amounts of water vapor. So M. Douglas LeVan, Centennial Professor and chair of chemical engineering, is developing a system to convert carbon dioxide into oxygen and carbon monoxide. At the same time, Professor John A. Roth and Associate Professor Kenneth A. Debelak are studying a process that uses "supercritical" carbon dioxide to dissolve and extract minerals, water and other substances from the Martian dust. One of the biggest problems that the engineers face is the fact that they don’t have any Martian dirt or rock to test and study. Such materials will not be available until the successful completion of a Mars sample return mission that could launch as early as 2011. Until then the engineers must work with clues like the spectral data taken from earlier Mars missions. "We can only make educated guesses of what we'll find on Mars based on existing spectral data," Debelak says. "The data suggest we'll find certain elements, so we can predict a range of compounds that we can also expect to find, and we know which minerals are likely to hydrate. We also know which compounds could be used to make water." "Carbon dioxide makes up more than 95 percent of Martian atmosphere," Roth explains. "When carbon dioxide is compressed to a pressure of more than 1,100 pounds per square inch and 88 degrees Fahrenheit, it becomes a good solvent and is frequently used in industrial and agricultural applications. For example, supercritical carbon dioxide is used to make decaffeinated coffee. What we don't know is how supercritical carbon dioxide works with inorganic materials, such as the soil we expect to find on Mars." So, in the first year of a four-year grant, Roth and Debelak have focused on testing the solubility of inorganic compounds in supercritical carbon dioxide. In the supercritical state, CO 2 molecules behave with properties of both liquids and gases. By increasing the pressure, this characteristic -1- Learning to live off the land, Martian style can be put to work to dissolve materials which crystallize or condense out of the fluid when the pressure is reduced. "We need more information to help guide mathematical models and theoretical calculations of how supercritical carbon dioxide behaves," Roth says. To gain this data, he and Debelak are screening a variety of compounds to see which ones are soluble in supercritical carbon dioxide. "We already know that certain forms of nickel, titanium, aluminum and magnesium are soluble…, Debelak says. "The question we're ultimately trying to answer is whether we can use supercritical carbon dioxide as a universal solvent on Mars to get water, fuel and building materials from the soil," Debelak says. "If we can get water, then we can separate that into hydrogen for fuel and oxygen to breathe." Meanwhile, LeVan is developing equipment to make breathable air and fuel from the Martian atmosphere. He and his associates are working with teams from NASA Ames Research Center and the University of Arizona to develop a three-phase system that takes carbon dioxide from the atmosphere and separates it into oxygen for breathing and carbon monoxide, which can be used for fuel as well as the production of hydrocarbons and plastics. LeVan is concentrating on the final step in the process. LeVan’s device takes the mixture of carbon monoxide and carbon dioxide produced by the two preceding stages—under development by NASA and the University of Arizona—into a bed of material that adsorbs CO2. Adsorption can separate the two gases because they react differently to certain substances. As the CO/CO2 mixture flows through the adsorption bed, the carbon dioxide is adsorbed and carbon monoxide passes through so it can be pumped off and stored for use as fuel and feedstock. The carbon dioxide caught in the adsorption bed is held inside the separator until the heat and pressure reach a high enough level to free it. When it is released, the gas is shunted into a recycling conduit that carries it upstream of the NASA-designed, solar-powered compressor. There, the recycled gas is mixed with fresh carbon dioxide from the Martian atmosphere and reacted in a special chamber to produce oxygen, carbon dioxide and carbon monoxide. The oxygen is separated and stored for fuel or breathing before the carbon dioxide/carbon monoxide stream is fed to the adsorption separator. "We're working now to identify the best adsorbent for carbon dioxide," LeVan says. "We then will begin working on our prototype separator, which we expect to complete in two years." Carbon dioxide and carbon monoxide vary both in how fast and how tightly they attach to different kinds of adsorbent particles. LeVan and his associates are currently measuring these characteristics for zeolitic materials, have mapped the behavior of numerous adsorbents with various gas mixtures and have developed mathematical models of the processes. "We expect the equipment we're developing to be a highly efficient method of extracting lowgrade fuel from the Martian atmosphere," Professor LeVan says. - VU - -2-