Phenomenological Model of Cyclone Separator

advertisement

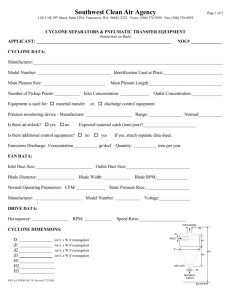

Phenomenological Model of Cyclone Separator Kuo-Tai Hsieh (謝國台), King-Jang Yang (楊錦章) and Chin-Hung Ko (柯慶宏) Department of Applied Mathematics, Chung Hua University No. 707, Sec. 2, Wufu Rd., Hsinchu, 30012, Taiwan, R.O.C. Tel: 03-518-6389, Fax: 03-518-6435 Email: kahsieh@chu.edu.tw, kingjang@chu.edu.tw, lhocvye@yahoo.com.tw Abstract The development of a mathematical model of cyclone separator based on physics of fluid flow provides details of gas flow and particle motion. The model is validated by comparing the predicted grade-efficiency with experimental data reported in the literature. A new particle tracking procedure proposed in this model accurately predicts the short-circuiting of coarse particles Keywords: cyclone separator, mathematical model, size classification, short-circuiting flow 1. Introduction upon which the current cyclone design is almost The cyclone separator is extensively used to entirely founded. This usually rests on a number of collect particles from gases in various industrial expressions to obtain an overall pressure drop, and processes. The reasons for its popularity lie in the more importantly a characteristic grade-efficiency simplicity low curve as a function of design and operating variables. maintenance and operating costs, and the small Some popular models include the Lapple (1951), physical size of the unit. In a typical cyclone Barth (1956), Leith-Licht (1972), Dietz (1982), and operation, particle laden gas entering the cyclone Iozia (1990) models [1-5]. Strauss [6] as well as from a tangential inlet causes a swirling motion Buonicore and Davis [7] gave reviews of cyclone within the device that generates centrifugal force. In design methods in current use. Over the years, the this centrifugal force field, solid particles move Navier-Stokes equations gradually made its way into towards the wall and are swept downwards to the model formulation with a number of assumptions. dust receiver where they are collected. As the gas Boysan et al. [8] proposed a mathematical model spirals down towards the apex, the direction of flow which provided all details of gas flow and particle is reversed since there is no outlet in the dust receiver; motion in a cyclone separator. They modeled the after which the gas spirals upwards in a central highly swirling flow by means of an algebraic column of fluid and exits through a vortex finder. Reynolds stresses approach. The time-averaged of its design and operation, A considerable amount of experimental data Navier-Stokes equations were solved by a exists on the behavior of flows in cyclones, obtained semi-implicit scheme developed by Patankar [9] with for the most part in the 1930s and 1940s before the the assumption of axisymmetry. Grade-efficiency availability of laser-Doppler anemometry. Although curves were obtained by a stochastic particle-tracking the reliability of this data can not be warranted, it has technique and showed fair agreement with the formed the basis of many semi-empirical correlations experimental data determined by Stairmand [10]. However, the three-dimensional inlet stream was solid phases within the cyclone. A full multiphase improperly two-dimensional approach will not be pursued, as it would be difficult formulation. Consequently, the short-circuiting of to keep computation time reasonable. In view of the coarse particles was greatly underestimated. By fact that the dispersed phase is dilute and the particle adopting the turbulence model, Yoshida et al. slip velocities are likely to be small, alternatively, we [11] solved the three-dimensional Navier-Stokes assume that particle-fluid momentum coupling is equations numerically. They indicated that flow field absent and thus break the modeling work into two of the cyclone changes with circumferential angle, parts. First, the gas-phase fluid-flow problem is and that upward and downward velocity components solved to predict gas-phase velocities; then, the merge strongly near the entrance of the dust receiver. particle motion with respect to fluid is computed by They also obtained fair agreement between calculated balancing all forces acting on the particle itself. We and experimental particle separation efficiency. postulate that if we can calculate particle slip However, the turbulence closures based on the velocities, then particle trajectories of each particle assumption of isotropy have been found to be size, from inlet to outlet can be predicted. This in turn inapplicable in the case of highly swirling flows. yields the grade-efficiency curve of the cyclone. modeled in a Besides, they did not validate the computed flow 2. Modeling of the Gas Phase field. The swirling fluid flow is a classic fluid mechanics problem which can be analyzed with the Navier-Stokes equations. The difficulties, however, are that the current system comprises multiple phases − gas, and solid particles (each particle size represents an additional phase), and that the swirling flow is turbulent. By introducing a new particle tracking procedure, the objective of this study is to model cyclone performance with the Navier-Stokes equations. The unique aspect of modeling in this manner is that in a numerical solution, the geometry of a cyclone is implicitly accounted for. Hence, a validated model is useful for the design of cyclones modeling through a single-inlet will quickly distributes itself around the cylindrical section; axisymmetry is naturally assumed for this modeling work. The assumption of axisymmetry implies that the inlet flow has to be distributed in some manner to obtain appropriate initial conditions for this two-dimensional model. It is therefore decided to model the inlet flow through a full 360° inlet ring [12], which allows the same amount of fluid to enter the cyclone. Although it is possible to numerically solve the governing Navier-Stokes equations written in primitive variables, many successful solutions have in specific applications. Complete It is believed that particle laden gas entering work of cyclone performance involves predicting gas phase velocities, slip velocities of particles with respect to the gas phase, and ultimately the grade-efficiency curve of the device. The problem becomes complex, because utilized the vorticity-stream function approach. For two-dimensional incompressible turbulent flow, with constant properties and adding to this complexity is the presence of gas and the dimensionless modeled transport equations are as follows [12]. the governing fluid-flow equations are non-linear, simultaneous partial differential equations, and no body forces, Vorticity: 1 2 u w t r3 z r z viscosity/diffusivity concept, which relates turbulent (1) 1 1 Re r 2 r r r 2 z 2 2 2 For boundary-layer flow developing over rigid boundaries, the mixing-length hypothesis combines a Stream function: good mixture of accuracy and simplicity. Therefore, a 2 1 2 r r2 r r z2 (2) v v w r r r t m 2 u u w t r r z (3) 1 1 Re r 2 r r z 2 2 modified Prandtl mixing-length model [12] will be used in this modeling work which reads: Angular spin velocity: transport terms to gradients of mean-flow quantities. 2 (5) It should be noted that variables with an overbar represent their respective dimensional quantities. The proposed turbulence model takes into account the and effect of the presence of solid particles on fluid 1 1 w, u, v, r r r z r (4) turbulence by assuming a particulate density that depends on solid concentration. A turbulent viscosity where Re is Reynolds number defined as RcU 0 . It that in turn depends on the particulate density and should be noted that the normalization constant used viscosity is also assumed. Equation 5 involves a here is based on the advective time scale Rc U 0 , single unknown parameter, the mixing-length , where Rc is the cyclone radius and U 0 is the mean which is a characteristic length scale of turbulent inlet velocity. motion and whose distribution over the flow field has Although the correlation between turbulence and to be prescribed with the aid of empirical information. Reynolds number has not been established for We consider that the mixing length varies both vortical flow, it is generally believed that turbulent radially and axially in a typical cyclone operation, conditions exist within the body of the cyclone, and propose the following correlation: especially since the inlet Reynolds number is as high as 105 to 106 for most practical applications. 1 4 R r 0 . 2 R0c z Rc Rc 1 2 (6) Reviews on models available for calculating turbulent Where Rz is the radius of the cyclone at the stresses are abundant in the literature [13-14]. horizontal level under consideration. Use of the turbulence model in its standard form is The boundaries where steady-state conditions unrealistic for the current system, since anisotropy is must be specified are the inlet, the outlet, and the imposed on the flow by high swirling stresses [15]. solid wall. The inlet conditions are known beforehand. The algebraic stress model proposed by Boysan et al. Therefore, a mass inflow of gas and a concentration [8] is, on the other hand, too complicated and time of solids are preset at the beginning of computation. consuming. In addition, it does not take into account Conditions at the outlet are not known, and the effect of presence of solid particles on the zero-gradient conditions are applied. Values of properties of fluids. The Prandtl mixing-length angular spin velocity at the wall are approximated by hypothesis is one of the first turbulence models a logarithmic wall function. Boundary values of proposed, and interestingly is still among the most vorticity are more difficult to obtain and are widely extremely used models. It employs the eddy important quantities. The vorticity transport equation for t determines how is advected and diffused. Total is conserved at 36.7mm interior points, but at the no-slip boundary is produced. It is in fact the diffusion and subsequent advection of vorticity, which is produced at the wall that drives the problem. If w 1 is expanded by the 225mm 75mm Taylor series around the wall value w and the no-slip condition is used, we get: r w 2 Where w 1 w n2 O (n) (7) 100mm 124mm 165mm n is the dimensionless distance from ( w1) to w, normal to the wall. The numerical problem on hand is a set of coupled parabolic and elliptic partial differential equations. Equations 1 and 3 are parabolic, and they pose an initial-value problem. These equations are 405mm solved using the Hopscotch method, where a solution is stepped out from some initial conditions. Equation 2 is elliptic which poses a boundary-value problem, and is solved by the successive over-relaxation (SOR) 75mm 20mm method. A rectangular mesh system has been adopted where small radial mesh size would be favored due to high velocity gradient in the radial direction. A small axial mesh size should also be used in the vortex Fig. 1 Cyclone separator finder region to account for short-circuiting flow; while in the conical part, it has been set in such a way Figure 2 shows the predicted tangential velocity that the node points fall exactly on the conical wall. profile, flow field, and streamlines. When modeling The iterative scheme starts from the establishment of highly swirling flows, it has been found that the initial values of , , , u and w everywhere at t correct prediction of the tangential velocity is = 0, and converges to the correct solution after essential to adequately reproduce the rest of the flow performing a number of iterations. field. The largest tangential velocity appears in the inlet zone. A forced-free vortex is well predicted by 3. Predicted Gas-Phase Flow Patterns The dimensions of a 225-mm cyclone with apex cone used in this study are shown in Fig. 1. We adopt the same design parameters and operating conditions as those of Bohnet’s experiments [16]. Specifically, the gas flow rate to the cyclone was 0.05 m 3 sec and the mean inlet velocity was 13.6 m sec . the model. The peak tangential velocity at each horizontal level decreases as the gas spirals downwards. Due to the presence of an apex cone, the tangential velocity drops rapidly as the gas enters the dust receiver. The short-circuiting flow in the upper part as well as the flow reversal are observed in the flow field. Non-swirling velocity components are very small in the dust receiver and thus drastically tracked from the inlet to either the dust receiver or the reduce the re-entrainment of fine particles. The outlet. Depending on the size of each particle, there is streamlines show the expected upward and downward lag in the gas velocity. Particle slip velocities are moving streams. It is estimated that about 6.3% of the determined by a dynamic force balance on the inlet gas stream short-circuits to the vortex finder, particle itself. For a particle of diameter d p and and 9.0% of the total gas stream flows through the density p , by balancing the centrifugal force dust receiver. against the radial drag force and then solving for the Tangential Velocity 30 24 18 12 6 0 m/sec Flow Field radial slip velocity u s , we obtain Streamlines ( ψ ×10 ) 6 0 mm 4 p m us 3 g 30 60 197 90 density, and 150 757 180 12 (8) Where m is the particulate density, g is the gas 500 120 v 2 dp r CD CD is the drag coefficient [15]. Similarly, by balancing the gravity force against the 210 axial drag force and solving for the axial slip velocity 1375 240 ws , we have 270 300 4 p m ws 3 g 2712 330 360 dp g CD 12 (9) 4140 390 5. Predicted Particle Trajectories and Grade-Efficiency 420 5549 450 As shown in Fig. 3, the gas stream translates 480 510 from a vertical plane containing line 6857 AB to 540 another vertical plane including line AB after entering 570 the cyclone through a tangential inlet. In other words, 600 7450 630 the fluid flows in a non-swirling fashion. Since there 7760 660 are no significant forces acting on the particles 7957 690 contained in the gas stream, they move along Fig. 2 Predicted tangential velocity profile, flow field, and streamlines swirling motion of the gas stream will not take place until it passes plane ABCD, where the linear 4. Modeling of the Particulate Phase The general performance of cyclones is influenced both by design variables such as cyclone dimensions, and also by operating variables such as particulate concentration streamlines of the gas phase in the inlet zone. The and gas flow rate. Grade-efficiency curves are commonly used to evaluate cyclone performance. To determine this curve, trajectories of particles for each size must be momentum of the gas stream starts to distribute into the tangential, axial, and radial directions. We therefore propose a new particle tracking procedure that starts from plane ABCD instead of a peripheral line segment AD. Incidentally, we divide plane ABCD into 100 49 entry points where the particle tracking procedure begins. For a tangential inlet, we postulate that particles of any size are equally likely to be present at any of the aforementioned entry points. For an involute inlet, however, particles will be unevenly distributed among these entry points because centrifugal force already affects particle motion as they enter the cyclone. r This in turn r z z reduces the short-circuiting of coarse particles to a certain extent. Starting from each of the entry points, dp = 0.8 μm dp = 1.7 μm dp = 2.0 μm dp = 3.0 μm the particle tracking procedure begins. Particle displacement for a small time interval is calculated. dp = 0.8 μm dp = 1.7 μm dp = 2.0 μm dp = 3.0 μm The computational routine is repeated until the particle is collected or exits the cyclone through the vortex finder. A A' B' B 49 A B 100 D C (a) (b) Fig. 4 Computed particle trajectories at which it enters the cyclone. As seen in Fig. 4a, after entering the cyclone from a peripheral entry point 10 mm below the roof, all particles move downwards along the cylindrical section and then into the conical part. Strong inward flow in the conical section brings fine particles toward the axis of symmetry. These fine particles reverse flow direction after passing their respective equilibrium orbits, and move toward the vortex finder along with the central upward flow. As for the coarse particles, the large Fig. 3 Entry points of particle trajectories centrifugal force pushes them toward the conical wall despite the strong inward flow. Then they join the The essence of the cyclone’s separation effect is clearly demonstrated in Fig. 4, where trajectories of four different size particles are shown. The trajectory of a particle depends on both its size and the location boundary-layer flow along the conical wall into the dust receiver, where they are collected. Particle trajectories that start from a peripheral entry point 80 mm blow the roof display a similar pattern as seen in Fig. 4b. Although in both cases, 0.8 m particles short-circuit to the vortex finder should they start escape and 3.0 m particles are collected; the from entry point B. outcome of intermediate size (1.7 and 2.0 m ) For a certain particle size in the inlet stream, the particles is quite different. While in one case these particle trajectories are tracked from each of particles escape as shown in Fig. 4a; they are the 100 49 entry points. The number of particle collected in the other case as seen in Fig. 4b. trajectories terminating at the dust receiver divided A A' B' B' B by the total number of entry points denotes the A A' collection efficiency of that particle size. Repeating B this procedure for all particle sizes in the inlet stream yields a grade-efficiency curve. It should be noted that, based on Bohnet’s experimental conditions, r B A particles are assumed to move through dilute r z z A particulate where particle/particle interactions are B negligible. dp = 3.5 μm dp = 3.5 μm 100 80 60 This Model Experimental (Bohnet) Barth Model Lapple Model 40 20 Dietz Model 0 2 4 PARTICLE DIAMETER 6 8 10 ( MICRONS ) Fig. 6 Predicted and experimental grade-efficiency (a) (b) Fig. 5 Short-circuiting of coarse particles Grade-efficiency curve predicted by this model is compared with Bohnet’s experimental results in Fig. 6. This model will not only predict the cut size The short-circuiting of coarse particles to the accurately but also the entire grade-efficiency curve vortex finder is clearly seen in Fig. 5. For with precision. The new particle tracking procedure 3.5 m particles entering the cyclone from any entry proposed in this model seems to work extremely well, point 20 mm below the roof, they are all collected as since the short-circuiting of coarse particles is closely shown in Fig. 5a. For particles of the same size predicted. It is believed that deficiency of the entering the cyclone from entry points 80 mm below hypothetical ring inlet in the model formulation has the roof, however, the outcome could be different been remedied by this new particle tracking depending on the respective location of entry points. procedure. Grade-efficiency curves predicted by a As can be seen in Fig. 5b, while particles are number of semi-empirical models reported in the collected if they start from entry point A; they literature are also shown in Fig. 6. Considerable discrepancies are observed both in cut size and general trend of the separation curve. Specifically, the collection efficiency of coarse particles is greatly underestimated by these models. [6] Strauss, W., “Industrial Gas Cleaning,” Pergamon, 1966, Ch. 6. [7] Buonicore, A.J. and Davis, W.T., “Air Pollution Manual,” Van Nostrand Reinhold, 1992, Ch. 3, pp. 71-78. 6. Conclusions [8] Boysan, F., Ayers, W.H. and Swithenbank, J., “A Based on the physics of fluid flow, a theoretical approach to the modeling of cyclone performance has been developed. Close agreements between predicted and measured grade-efficiency characteristics indicate that the basic construction of the model is sound and well justified. The fundamental mathematical modeling technique is capable of providing detailed information about the gas and particle dynamics within the device. In addition, this information allows for a better understanding of the short-circuiting mechanism, so that a rigorous approach to cyclone separator design can be undertaken. Fundamental Mathematical Modeling Approach to Cyclone Design,” Trans. Institution of Chemical Engineers, Vol. 60, 1982, pp. 222-230. [9] Patankar, S.V., “Numerical Heat Transfer and Fluid Flow,” Hemisphere, 1980. [10] Stairmand, C.J., “The Design and Performance of Cyclone Separators,” Trans. Institution of Chemical Engineers, Vol. 29, 1951, pp. 356-383. [11] Yoshida, H., Saeki, T., Hashimoto, K. and Fujioka, T., “Size Classification of Submicron Powder by Air Cyclone and Three-Dimensional Analysis,” Journal of Chemical Engineering of Japan, Vol. 24, 1991, pp. 640-647. [12] Hsieh, K.T. and Rajamani, R.K., “Mathematical References [1] Lapple, C. E., “Process Uses Many Collector Model of the Hydrocyclone Based on Physics of Types,” Chemical Engineering, Vol. 58, 1951, pp. Fluid Flow,” AIChE Journal, Vol. 37, No. 5,1991, 144-151. pp. 735-746. [2] Barth, W., “Design and Layout of the Cyclone [13] Rodi, W., “Examples of Turbulence Model for Separator on the Basis of New Investigations,” Incompressible Flows,” AIAA Journal, Vol. 20, Brennstoff-Warme-Kraft, Vol. 8, No. 4, 1956, pp. No. 7, 1982, pp. 872-879. [14] Sloan, D.G., Smith, P.J. and Smoot, L.D., 1-9. [3] Leith, D. and Licht, W., “The Collection “Modeling of Swirl in Turbulent Flow Systems,” Efficiency of Cyclone Type Collectors ─ A New Progress of Energy Combustion Science, Vol. 12, Theoretical Approach,” AIChE Symposium series, 1986, pp.163-250. [15] Pericleous, K.A., Rhodes, N. and Cutting G.W., Vol. 68, No. 126, 1972, pp. 196-206. [4] Dietz, P.W., “Electrostatically Enhanced Cyclone Separators,” Powder Technology, Vol. 19, 1982, pp. 221-226. [5] Iozia, D.L. and Leith, D., “The Logistic Function and Cyclone Fractional Efficiency,” Aerosol “A Mathematical Model for Predicting the Flow Field in a Hydrocyclone Classifier,” Proceedings of International Conference on Hydrocyclones, 1984, pp. 27. [16] Bohnet, M., “Cyclone Separators for Fine Science and Technology, Vol. 12, 1990, pp. Particles and Difficult Operating Conditions,” 598-606. KONA, No. 12, 1994, pp. 69-76.