Carbon Footprint

advertisement

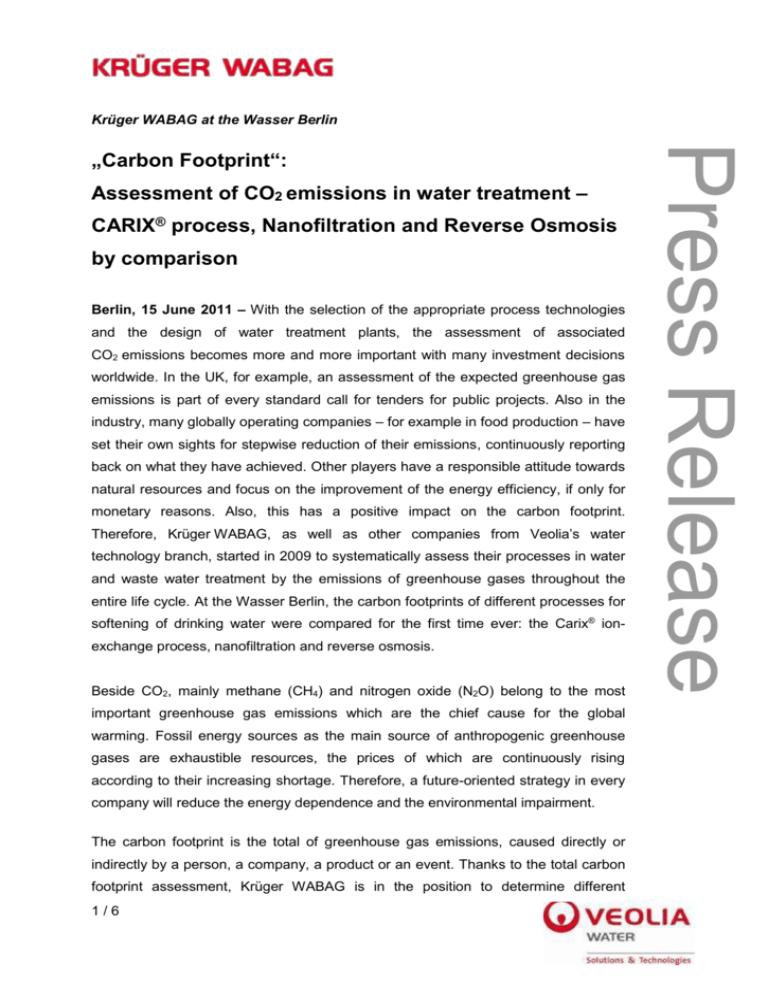

Krüger WABAG at the Wasser Berlin Assessment of CO2 emissions in water treatment – CARIX® process, Nanofiltration and Reverse Osmosis by comparison Berlin, 15 June 2011 – With the selection of the appropriate process technologies and the design of water treatment plants, the assessment of associated CO2 emissions becomes more and more important with many investment decisions worldwide. In the UK, for example, an assessment of the expected greenhouse gas emissions is part of every standard call for tenders for public projects. Also in the industry, many globally operating companies – for example in food production – have set their own sights for stepwise reduction of their emissions, continuously reporting back on what they have achieved. Other players have a responsible attitude towards natural resources and focus on the improvement of the energy efficiency, if only for monetary reasons. Also, this has a positive impact on the carbon footprint. Therefore, Krüger WABAG, as well as other companies from Veolia’s water technology branch, started in 2009 to systematically assess their processes in water and waste water treatment by the emissions of greenhouse gases throughout the entire life cycle. At the Wasser Berlin, the carbon footprints of different processes for softening of drinking water were compared for the first time ever: the Carix® ionexchange process, nanofiltration and reverse osmosis. Beside CO2, mainly methane (CH4) and nitrogen oxide (N2O) belong to the most important greenhouse gas emissions which are the chief cause for the global warming. Fossil energy sources as the main source of anthropogenic greenhouse gases are exhaustible resources, the prices of which are continuously rising according to their increasing shortage. Therefore, a future-oriented strategy in every company will reduce the energy dependence and the environmental impairment. The carbon footprint is the total of greenhouse gas emissions, caused directly or indirectly by a person, a company, a product or an event. Thanks to the total carbon footprint assessment, Krüger WABAG is in the position to determine different 1/6 Press Release „Carbon Footprint“: solutions for water treatment and indicate possible savings with the associated costs and hardness components, sulphate and nitrate from drinking water. Tested were the CARIX® ion-exchange process, nanofiltration and reverse osmosis. The assessment The survey carried out is based on the values of a CARIX® unit being in operation with the actual operating costs and consumptions. This unit is compared with a nanofiltration unit and a reverse osmosis unit, both of an analogue design. A common index is the CO2 equivalents (g CO2/m3 product water) being generated during the entire lifecycle of the CARIX®, nanofiltration and reverse osmosis units. For all three cases, an average lifecycle of 25 years was taken as a basis. The basic output of each plant is 244 m3 of water per hour. The total emissions are divided into three main categories: Emissions being generated during the operation of the unit (raw water supply, electric power consumption and operating materials) Emissions being generated during engineering and construction of the unit Emissions being avoided due to the CO2 consumption For calculation of emissions during engineering and construction of the units, each individual component of the system is assessed independently. The different raw materials such as steel, aluminium and various types of plastic materials are quantified and multiplied by their respective CO2 emission coefficients. The coefficients used by Krüger WABAG and Veolia Water Solutions & Technologies come from several internationally accepted databases. The most important factors for the operating period are the types of raw water being used, energy consumption and consumable materials. 2/6 Press Release advantages, for example, with processes for partial desalination and removal of Test result of the comparatively low electric power consumption and the reduction of emissions by the CO2 being bound in the waste water. Compared with the CARIX® unit, the carbon footprint of the nanofiltration and reverse osmosis units were 68% and 88% higher, respectively. That is they have major effects on the climate and the environment as well as considerably higher operating costs (see fig. 1). The CARIX® (carbon dioxide regenerated ion-exchangers) unit consists of ionexchange resins where the partial desalination and removal of hardness components occurs. The reaction product is carbonic acid which breaks down into water and CO2. In the downstream pure water degasifier, the CO2 is removed again from the water by air stripping. For regeneration of the ion-exchanger filters, CO2 from the recovery as well as from a CO2 tank is used instead of chemicals. Thus, an increased salt content in the waste water can be avoided. The CO2 used in the process is provided from a waste gas which is generated as a waste product from fertiliser production (ammonia synthesis) and which would otherwise pass into the atmosphere. In the eluate degasifier, CO2 is recovered to about 95% from the regeneration flow. The remaining part is chemically bound in the waste water and then conveyed into the discharge system (see fig. 2). One important finding from the investigation: With all three units, the biggest share of emissions comes from the electric power consumption during plant operation. The category raw water supply during operation registers emissions connected with the energy consumption due to generation of additional raw water. The emissions resulting during plant engineering and construction, as well as emissions resulting from the production of the operating materials, only represent a small share of the total emissions. The ”avoided emissions“ are the share of greenhouse gases being bound and prevented to pass into the atmosphere. Further information on www.krueger-wabag.de; contact krueger-wabag@veoliawater.com 3/6 Press Release With 161 g CO2-e/m3, CARIX® unit has the lowest carbon footprint, which is a result Picture 1: Emission per m3 350 CARIX Nanofiltration Reverse osmosis 300 CO2 trapped in wastewater 250 Water consumption Carbonic acid 200 Antiscalant g CO2-e/m3 Energy, add. raw water feed. 150 Energy, operation (+10%) Electronic components Irrigator PP/PE 100 Membranes Exchanger resin 50 Pipes, PP/PE Steel, tanks 0 Steel, pipelines CARIX -50 -100 4/6 Press Release Picture 2: Picture 4: Carix® plant Picture 5: Reverse osmosis plant 5/6 Press Release Picture 3 Krüger WABAG, like Berkefeld, belongs to Veolia Water Solutions & Technologies. At its sites in Celle, Zwenkau near Leipzig and Bayreuth, more than 450 employees plan, develop and service projects for water and wastewater treatment. A network of more than 50 service technicians and 30 sales engineers throughout Germany ensures competent and speedy support. Veolia Water Solutions & Technologies (VWS), subsidiary of Veolia Water, is a leading design & build company and a specialized provider of technological solutions in water treatment. With over 9,600 employees in 57 countries, Veolia Water Solutions & Technologies recorded revenue of €2.15 billion Euros in 2010. Veolia Water, the water division of Veolia Environnement, is the world leader in water and wastewater services. Specialized in outsourcing services for municipal authorities, as well as industrial and service companies, it is also one of the world's major designers of technological solutions and constructor of facilities needed in water and wastewater services. With 96,000 employees in 67 countries, Veolia Water provides water service to 100 million people and wastewater service to 71 million. Its 2010 revenue amounted to €12.1 billion. Press contact: Krüger WABAG VWS Deutschland GmbH Veolia Water Solutions & Technologies Stefan Jakubik Press spokesman, Head of Marketing & Communications Lückenweg 5, 29227 Celle, Germany Phone: +49 (0) 5141 803-174 Mobile: +49 (0) 151 12559226 stefan.jakubik@veoliawater.com www.berkefeld.de 6/6 Press Release Company Profile