ENVIRONMENTAL PROTECTION - REPORT FOR 2011

advertisement

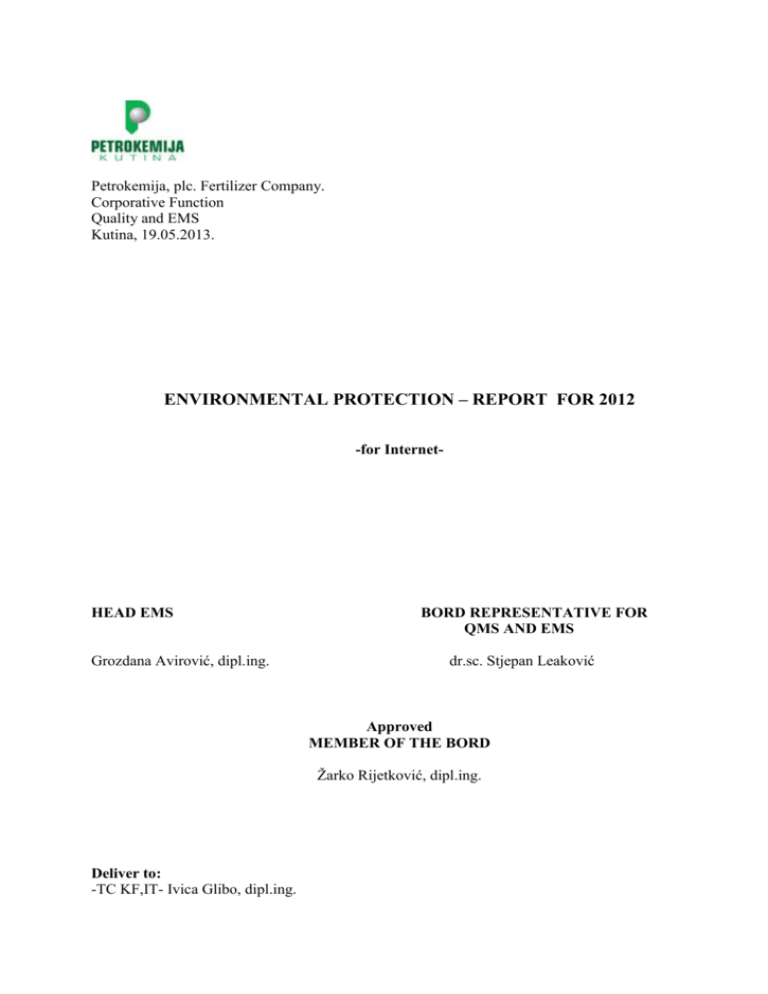

Petrokemija, plc. Fertilizer Company. Corporative Function Quality and EMS Kutina, 19.05.2013. ENVIRONMENTAL PROTECTION – REPORT FOR 2012 -for Internet- HEAD EMS Grozdana Avirović, dipl.ing. BORD REPRESENTATIVE FOR QMS AND EMS dr.sc. Stjepan Leaković Approved MEMBER OF THE BORD Žarko Rijetković, dipl.ing. Deliver to: -TC KF,IT- Ivica Glibo, dipl.ing. 2/6 ENVIRONMENTAL PROTECTION - REPORT FOR 2012 Introduction Petrokemija Plc., with its basic activities of fertilizer production, carbon black production and bentonite clay-based products has a significant impact on environment. Major environmental aspects are pollutant emissions to air and water and waste management. The overall objective of the Company is to improve the performance of the environmental management system in order to achieve a more effective environmental protection and pollution prevention. The frame and the main guidelines of the strategic activities in the environmental and quality management are established by the Environmental and Quality Policy. The key parts of the environmental management system, their mutual effect and connections between organizational units are described in Environmental Manual. The basic components of the environmental management process are planning the environmental protection activities in accordance with legal and other requirements, realization of the activities and assessment of environmental aspects in order to prove the environmental protection improvement by measurable indicators. The Environmental Management System of Petrokemija was made compliant with and certified against the ISO 14001:2004 standard requirements. 1. Air pollutant emissions The greenhouse gases, carbon dioxide and nitrous oxide were the most represented pollutants in total emission to air from Petrokemija Plc. in 2012, the same as in the earlier years, with a share of 99 %. As regards other characteristic emissions (ammonia-NH3, sulfur dioxide-SO2, nitrogen oxides-as NO2, gaseous fluorides-HF and dust), without greenhouse gases and carbon monoxide (CO), ammonia and nitrogen oxides (as NO2) were the most represented pollutants in the emissions from Petrokemija with a share of 62.21 % and 26.78 % respectively (Figure 1). Figure 1. Relative share of pollutants in air emissions of characteristic pollutants in 2012 2012.g. 9,918% 1,087% 26,779% 0,003% 62,213% SO2 NO2 HF NH3 PM 10 The total air emission in t/y (without carbon oxides: CO and CO2) was about 1 % higher as compared to that in 2011. Individually by pollutants (without carbon oxides: CO and CO2 and N2O), compared to 2011, the emitted amounts (t/y) in were lower for nitrogen dioxide (1.88 %) and dust emission (16 %) but higher for NH3, SO2 and fluorides. 3/6 As regards emission factors (kg/t) of individual pollutants, an increase per product unit was established for all pollutants in comparison to those in 2011, except for dust. With regard to the inforce prescribed emission limits, in line with the Regulation on Emission Limit Values...(OJ 21/07 and 150/08), the limit emission concentrations for ammonia, dust, nitrogen dioxide and sulfur dioxide exceeded in several cases at several outlets. Figure 2. Share of individual pollutants in total air emissions (t/y) of characteristic pollutants for 2008 - 2012 8000,00 7000,00 6000,00 H2S 5000,00 F SO2 4000,00 dust 3000,00 CH4 NO2 2000,00 NH3 1000,00 0,00 2008. 2009. 2010. 2011. 2012. With the aim of further improvement, measures are being undertaken for bringing the existing facilities in compliance with the Environmental Protection Act as prescribed in the Adjustment Plan adopted by the European Commission. Priority improvement measures are designed to improve the operations at the NPK1 and UREA Plants as well as measures to reduce greenhouse gas emissions at Nitric Acid 1 and Nitric Acid 2 plants. 2. Air quality in the Kutina area In 2012, on the basis of results of air quality monitoring at six measuring stations of the local network (Figure 3), for 7 pollutants (NH3, SO2, NO2, H2S, HF, dust and total sediment), 1st category (clean or slightly polluted air) was established for all pollutants except for ammonia at measuring station 03: Meteorological site (Table 1). According to unofficial measuring results of the State Measuring Station for hydrogen sulphide concentrations, 2nd category or polluted air was determined. Values of H2S cannot be associated with the Petrokemija production due to the halt of carbon black production. 4/6 Figure 3. Air quality monitoring network Table 1. Air quality categorization of the City of Kutina area at measuring stations in 2012 Regulation... OJ 133/05 Year* 2012. Clean or slightly polluted air 1st category C<GV 02,06, DMP 01,02,03,05,06,07 01,02,03,06,07, 01,02, 05,06,07, DMP 01,02,03,05,06,07, DMP 02,07, 01,02,03,05,06,07 DMP Moderately polluted air 2nd category GV<C<TV 03 DMP Excessively polluted air 3rd category C > TV Pollutant Sulfur dioxide Smoke Sediment Ammonia Nitrogen-dioxide Hydrogen sulfide Fluorides PM10 Key: Measuring stations : 01: Health center (K1) 02: Fire station (K2); 03: Meteorological site (K3); 05: Sports center (K5); 06: Husain (K6); 07: Krč (K7) DMP: State Measuring Station; C: Concentration; GV: Air quality limit value; TV: Air quality tolerance value; PM10: particles of 10µm diameter Although the long-standing concentrations of all characteristic air pollutants have a falling trend (e.g. ammonia, Figure 4.). Same goes for the mean concentration trend for the past five years, except for sulfur dioxide and fluorides. 5/6 100 90 80 70 60 50 40 30 20 10 0 1,80 1,60 1,40 1,20 1,00 0,80 0,60 0,40 Production Mt/y Conc.NH3 (microgram/m3) Figure 4. Trend of average annual ammonia concentration in the Kutina air and production trend for 1985-2012 period 0,20 0,00 85. 86. 87. 88. 89. 90. 91. 92. 93. 94. 95. 96. 97. 98. 99. 00. 01. 02. 03. 04. 05. 06. 07. 08. 09. 10. 11. 12. Conc. NH3 microgram/m3 Production PG Mt/y Trend of fertilizer production Mt/y Trend of concentration NH3 microgram/m3 Figure 5a. Waste water pollution expressed by pollution factor k1 and trend for 2008-2012 period Figure 5b. Total nitrogen (Total N) concentration for 2008-2012 period 1,25 50 Total N (mg/l) 1,2 1,15 k1 1,1 1,05 1 40 30 20 10 0,95 0 0,9 2008 2009. k1 2010. 2011. Trend k1 2012. 2008. 2009. Total N (mg/l) 2010. LV 2011. 2012. Trend Tot. N (mg/l) 4. Waste management In the course of 2012, Petrokemija Plc. together with municipal solid waste generated 30 kinds of industrial waste, 14 of which were hazardous. In addition, 4 kind of external waste was treated, 2 of which were hazardous. Approx. 78% of total quantity of waste handled within Petrokemija Plc. was disposed at the Company's own disposal, and the rest was given to external authorized waste collectors or processing companies. In 2012, no phosphogypsum waste was generated due to the temporary shutdown of phosphoric acid production. As regards the results of obligatory monitoring of the phosphogypsum disposal environment, the average annual concentration of underground water pollution (Figure 6.) was under the limit values for drinking water. 6/6 Figure 6. Average annual concentration of fluorides (F-) and phosphates (P) in underground water around Phosphogypsum Disposal in 2008 to 2012 period and comparison with maximum allowable concentration (MAC) and control well (k.b) in Radićeva Street P (mg/l) F- (mg/l) MAC za P MAC za F- k. b. 20 12 . 20 11 . ´1 0. ´0 9. ´0 8. 1,600 1,400 1,200 1,000 0,800 0,600 0,400 0,200 0,000