Document 5898014

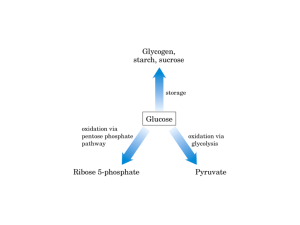

advertisement

BIOLOGICALLY-DRIVEN PHOSPHATE PRECIPITATION IN BIO-P SLUDGES. R. Elaine Dick*, Paul G. Devine, John P. Quinn1 and Stephen J. Allen School of Chemical Engineering/1School of Biology and Biochemistry/*QUESTOR (Queen’s University Environmental Science and Technology Research) Centre, Queen’s University, David Keir Building, Stranmillis Road, Belfast BT9 5AG, Northern Ireland, UK. *Corresponding Author: e-mail: r.dick@qub.ac.uk ABSTRACT Current processes for phosphate removal from wastewater are often regarded as dividing into either biological or chemical processes. However, during phosphorus removal in Bio-P sludges, the cellular efflux of phosphate that occurs naturally under anaerobic conditions prior to aerobic phosphorus removal causes local changes in the solution chemistry around the bacterial cells. If the conditions are favourable, bacteria can act as a seed for crystallisation and precipitation reactions. Such reactions have been observed in biological wastewater sludges. A combination of biological and chemical processes in a Bio-P sludge may increase the overall phosphate content of the sludges to a level that may be advantageous for phosphate recovery. The operation of a laboratory scale fill and draw system aims to optimise the conditions promoting precipitation of crystalline phosphates on the surface of phosphate-releasing cells during anaerobic conditions during Bio-P removal. This paper examines the conditions that are thought to promote such reactions, and how this phenomenon might be exploited for phosphorus recovery. INTRODUCTION In municipal wastewater treatment plants where there is a requirement to remove phosphate this may be done by either biological or chemical means. Enhanced Biological Phosphate Removal (EBPR) exploits the ‘luxury’ P uptake that occurs when biological sludges are cycled through appropriate anaerobic and aerobic conditions in a number of possible configurations such as “UCT” and “Phostrip”[1]. The process of EPBR uses the metabolism of specific bacteria, which under certain conditions accumulate large amounts of phosphate as intracellular polyphosphate. These bacteria use the degradation of polyphosphate to produce energy under anaerobic conditions with the release of phosphate into the wastewater (resulting in a transient increase in the phosphate content of the wastewater). The wastewater and activated sludge is then treated in an aerobic basin. Here the polyphosphate bacteria use stored carbon reserves to produce energy for growth and to replenish their stores of polyphosphate. The result is a net removal of phosphate from the wastewater (due to replenishment of polyphosphate in extant cells and de novo polyphosphate reserves in divided cells). Elaine Dick et al, page 1 Dick, R.E., Devine, P.G., Quinn, J.P. and Allen, S.J. 2 In chemical phosphorus removal metal salts such as iron, (Fe2+ or Fe3+) or aluminium (Al3+) are used to precipitate insoluble metal phosphates and to coagulate/flocculate suspended solids. The addition of chemicals, often dosed into biological sludges, increases sludge volumes - by up to 40% in the case of iron addition [1]. In addition, aluminium and iron containing sludges are not compatible with current methods for phosphate recovery [2]. Biological phosphate accumulating (Bio-P) sludges can contain 5-10% P, however, the form of this phosphorus, locked up in an organic sludge, is not readily available for phosphorus recovery. The ‘Phostrip’ process combines the biological accumulation with a step where the accumulated phosphate is released into a concentrated liquor and precipitated as a calcium salt. Although calcium produces low residual phosphate concentrations, effective precipitation requires a high pH (>10) and precipitates of CaCO3 may also be formed. Generally, more than stoichiometric quantities of cations must be added for the complete removal of phosphate. The two processes currently used for phosphate recovery from wastewater are based on the chemical precipitation of phosphate with Ca2+, or Mg2+ and NH4+ as struvite [1]. BIOLOGICALLY-DRIVEN PRECIPITATION The presence of crystalline phosphates in sludges has been observed in a number of studies [3, 4], and has been reported to be promoted by denitrifying conditions that also tend to raise the pH of the wastewater [3, 4]. Vivianite, Fe3(PO4)2.8H20, has also been found in sludges under anaerobic conditions following the addition of FeSO4 [6]. Microorganisms can specifically act as a seed for crystallisation and precipitation reactions when conditions are favourable. The unicellular alga Chlorococcum sp. has been shown to co-precipitate phosphate with calcite [7]. In Alcaligenes eutrophus CH34, the mechanism of heavy metal resistance - efflux of the metals, together with locally elevated levels of CO2 from cellular respiration resulted in precipitation of heavy metal carbonates [8]. Research on heavy metal removal by Lynne Macaskie’s group in the University of Birmingham showed that the cellular efflux of phosphate during organic phosphate degradation (Citrobacter sp.) [9] or inorganic polyphosphate hydrolysis (Acinetobacter spp.) [10] promoted metal phosphate precipitation on cell surfaces. In each of these cases, the active metabolism of the microorganism affected the chemistry of the solution around the cell in a way that favoured precipitation. Using microbial metabolism in such a way, the formation of metal phosphates can occur under conditions where the bulk solution chemistry is unfavourable. During anaerobic conditions in Bio-P sludges the efflux of phosphate from the cells results in a locally high phosphate concentration gradient. This can act as a thermodynamic driving force for the precipitation reaction. Although the precipitant, for example calcium, may be present in relatively low quantities, the excess of phosphate can help to exceed the metal phosphate solubility product. As this happens in the locality of the cell surface, adsorption reactions can also provide potential crystal nucleation sites. As anaerobic phosphate release is often accompanied by a rise in the pH [12] this could also be advantageous in promoting the formation of calcium phosphates. The precipitation of calcium phosphates in real wastewater is complex. This has been recently examined in detail by Maurer et al. [12] who demonstrated experimental calcium Dick, R.E., Devine, P.G., Quinn, J.P. and Allen, S.J. 3 phosphate precipitation with formaldehyde-inactivated sludge below pH 8.0. A model also showed favourable conditions for calcium phosphate precipitation at physiologically achievable pH values in nutrient removal plants would be promoted by phosphate and pH gradients due to cellular metabolism [13]. ANAEROBIC AEROBIC Influent wastewater containing phosphate mixed with EBPR sludge P-rich sludge Sludge settled: Wastewater low in phosphate separated from P-rich sludge Phosphate Polyphosphate Phosphate Remaining phosphate taken up by cells for growth and to reform polyphosphate Anaerobic release of phosphate by cells Addition of calcium as a precipitant Chemistry of the solution around cells favours precipitation Figure 1. Proposed operation of biologically driven phosphate precipitation. In initial cycles crystal nucleation is likely to be the rate-limiting step; in subsequent cycles precipitation will be more rapid. The goal is to produce a compact sludge containing precipitated phosphates in addition to biologically sequestered polyphosphate with a total phosphorus content higher than would be possible with either biological or chemical phosphate removal alone. ADVANTAGES TO COMBINING BIO-P REMOVAL AND PRECIPITATION If it were possible to promote chemical precipitation reactions within Bio-P sludge while at the same time avoiding the disadvantages normally associated with the addition of chemicals to sludges, namely the formation of voluminous flocculent sludge, there are potential advantages to be gained from combining chemical and biological P removal. Polyphosphate forming cells have a maximum storage capacity for polyphosphate, but the potential for surface phosphate precipitation is unlimited. It may be possible to optimise the anaerobic phosphate release in the presence of added cations to promote the formation of insoluble phosphate salts as crystals on the surface of phosphate-releasing cells. In the subsequent aerobic period, in which the bacterial cells reform their quotient of stored polyphosphate, the removal of phosphate from the wastewater would be enhanced. Over a number of anaerobic/aerobic cycles the precipitation process would build up a substantial phosphate content in the sludge. The sludge would thus contain two independent forms of phosphate – polyphosphate and crystalline phosphates, and have an enhanced content of total phosphorus which may make economic recovery of the phosphate possible. Dick, R.E., Devine, P.G., Quinn, J.P. and Allen, S.J. 4 It has been suggested that the presence of a precipitant may accelerate the extent and rate of phosphate release [14]. If, as is likely, the degradation of polyphosphate is a reversible reaction governed in part by the concentration of free phosphate, the reduction in phosphate concentration at the cell surface by precipitation reactions may serve to increase the magnitude of phosphate release. This in turn may have a positive effect on BOD removal and competitive advantage by polyphosphate accumulating bacteria. If it is intended to remove only part of the phosphate by precipitation, less than stoichiometric amounts of cations would be added. This may reduce the risk of competing reactions consuming the added precipitant. As only a proportion of the phosphate is removed, the remaining phosphate would re-form polyphosphate within the cell: the precipitated portion would increase only gradually. The ultimate phosphate content of the sludge would thus be a function of sludge age: a high sludge age is also desirable for EPBR. The additional phosphate precipitated within the biological flocs may increase the total phosphate content sufficiently to potentially make phosphate recovery attractive. This proposed process would have particular advantages in wastewater where the BOD:P ratio is low, especially in cases where the phosphate requiring removal is high. The process may be compatible with mainstream operation or it may be desirable to operate this as a side-stream process to minimise sludge volumes, interference from competing ions, and maximise the sludge age and phosphate content. LABORATORY-SCALE TESTS To test the feasibility of this approach, a fill-and-draw reactor with an operating volume of 5 litres has been set up and seeded with sludge from a full scale EBPR (Phostrip) plant (Milcote, England). Due to the potential difficulty of maintaining biological phosphate removal activity over long periods, our approach has been to operate the system for experimental periods of up to two weeks duration. Active liquor can readily be established as required from frozen sludge. This has provided a source of conditioned sludge for batch experiments and will enable the test of different precipitants and conditions within relatively short time periods. POTENTIAL FOR PHOSPHATE RECOVERY Should this approach be successful, sludge containing two independent forms of phosphate, polyphosphate and precipitated phosphate salts, would be formed. The amount of polyphosphate in the sludge at the end of each cycle should be relatively constant (typically 9% P for EBPR sludges); the proportion of additional phosphate precipitate present would increase with sludge age. Assuming that this approach is feasible, there still remains the problem of how to recover the phosphorus from the sludge. Research has shown that sludge incineration followed by water elution [15] can extract biologically-sequestered polyphosphate from EBPR sludges. However, the additional presence of calcium phosphates would likely require chemical extraction. Thermal treatment could also be used to eliminate the organic material present leaving an ash with a relatively high calcium phosphate content, although Dick, R.E., Devine, P.G., Quinn, J.P. and Allen, S.J. 5 the cost of sludge incineration is high. Other suitable methods are likely to depend on the phosphorus content achievable and the concentration of undesirable metals present in the sludge. REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Brett, S., Guy, J., Morse, G.K. and Lester, J.N., Phosphorus Removal and Recovery Technologies, Selper Ltd., London. (1977) Driver, J., Lijmbach, D., and Steen, I., Why Recover Phosphorus for Recycling, and How? Environ. Technol., 20, 651-663. (1999) Appeldoorn, K.J., Boom, A.J., Kortstee, G.J.J. and Zehnder, A.J.B. Contribution of precipitated phosphates and acid soluble polyphosphate to enhanced biological phosphate removal. Water Res., 26, 937-943. (1992) Carlsson, H. Aspegren, H., Lee, N. and Hilmer, A., Calcium phosphate precipitation in biological phosphorus removal systems. Water Res., 31, 1047-1055. Arvin, E. and Kristiansen, G.H. Phosphate precipitation in biofilms and flocs. Water Sci. Technol., 15, 65-85. (1983) Frossard, E., Bauer, J.P. and Lothe, F., Evidence of vivianite in FeSO4-flocculated sludges. Water Res., 31, 2449-2454. (1997) Hartley, A.M., House, W.A., Callow, M.E. and Leadbeater, B.S.C., Coprecipitation of phosphate with calcite in the presence of photosynthesizing green algae. Water Res., 31, 2261-2268. (1997) Diels, L., Dong, Q., van der Lelie, D., Baeyens, W. and Mergeay, M., The czc operon of Alcaligenes eutrophus CH34: from resistance mechanism to the removal of heavy metals. J. Ind. Microbiol., 14, 142-153. (1995) Macaskie, L.E., Empson, R.M., Cheetham, A.K., Grey, C.P. and Skarnulis, A.J., Uranium bioaccumulation by a Citrobacter sp. as a result of enzymatically mediated growth of polycrystalline HUO2PO4. Science, 257, 782-784. (1992) Dick, R.E., Boswell, C.D. and Macaskie, L.E., Uranyl phosphate accumulation by Acinetobacter spp. pp.177-186. In: Biohydrometallurgical Processing Volume II. Jerez, C.A., Vargas, T., Toledo, H. and Wiertz, J.V., (eds) University of Chile, Viña del Mar, Chile. (1995) Bond, P.L., Erhart, R., Wagner, M., Keller, J., and Blackall, L.L., Identification of some of the major groups of bacteria in efficient and nonefficient biological phosphorus removal activated sludge systems. Appl. Environ. Microbiol., 65, 40774084. (1999) Maurer, M., Abramovich, D., Siegrist, H. and Gujer, W., Kinetics of biologically induced phosphorus precipitation in wastewater treatment. Water Res., 33, 484-493. (1999) Maurer, M. and Boller, M. Modelling of phosphorus precipitation in wastewater treatment plants with enhanced biological phosphorus removal. Water Sci. Technol., 39, 147-163. (1999) Boswell, C.D., Dick, R.E. and Macaskie, L.E., The effect of heavy metals and other environmental factors on the anaerobic phosphate metabolism of Acinetobacter johnsonii. Microbiology, 145, 1711-1720. (1999) Matsuo, Y., Release of phosphorus from fly ash produced by incinerating waste activated sludge from enhanced biological phosphorus removal. Water Sci. Technol., 34, 407-415. (1996)