Development of Experimental Diagnostics for Measurement of

advertisement

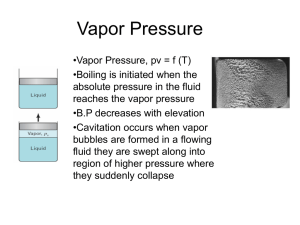

Development of Experimental Diagnostics for Measurement of Velocity, Temperature and Void Fraction in Cryogenic Simulant fluid Kayla M. Kuzmich Department of Mechanical and Aeronautical Engineering Abstract The United States Air Force is engaged in the advancement of fuel systems for its liquid rockets. Fuel systems require liquid hydrogen and oxygen to be kept at temperatures less than -238 oF and at pressures exceeding 500 psi. Previously these systems were developed by the fabrication and testing of multiple designs. This method is inefficient and can be streamlined with the application of Computational Fluid Dynamics (CFD). CFD employs numerical models of the fluid flow systems however, these codes need to be validated for accuracy to ensure their viability. Complications arise in performing validation experiments in liquid hydrogen and oxygen due to the high costs, extremely low fluid temperatures, high pressures, and the presence of cavitation observed in these fuel systems. Simulant fluids are used to mimic the behavior of liquid hydrogen and oxygen and ameliorate experimentation of these systems. The purpose of this research is to develop experimental techniques to validate CFD codes in cryogenic simulant fluids with the presence of cavitation. Molecular Tagging Velocimetry (MTV) is a measurement technique that utlizes molecules uniformly mixed throughout a fluid medium. The molecules are turned into long-lived tracers by excitation of photons at a specific wavelength. Regions of interest are “tagged” by a pulsed UV laser; then images of the tagged patterns are captured at two instances in their lifetime. The measurement of the Lagrangian displacement vector obtained from the images provides an estimate of the velocity vector. The first step of this work is to determine the optimal chemical concentration for application of MTV. The chemicals used in this application are cyclohexanol, cyclodextrin, and bromonaphthalene. Together they form the phosphorescent complex used in the measurements. To determine the optimal concentration levels a beaker containing 1.0 L of water, 0.04 mole of cyclohexanol, bromonaphthalene to saturation is mixed. The fluid is pulsed with a single beam Nd:YAG laser from above. A series of 100 pair images are captured with a CCD camera with a delay of 3.5 milliseconds between images in the pair. Images are then analyzed and a relation of beam intensity versus depth is determined. The concentration of the cyclodextrin is increased in 0.00002 mole increments to provide a map of intensity and attenuation versus concentration. In the second portion of this work an acrylic tank of dimensions 12”x12”x12” houses two, 6”x6”x1/4” quartz windows on opposing sides to allow the laser access to the fluid contained within. The fluid is a mixture of water and phosphorescent complex that of which the concentration was determined in the first portion of this work. Also contained in the tank is a Wedge-Lock ceramic plate air diffuser, this device creates micron sized bubbles uniformly distributed in a column. The bubbles produced are used to simulate cavitation found in the fuel systems of interest. Measurements are first done in the tank without bubbles and with minor fluid circulation. Analysis is done by comparing the intersections of the two beams and their displacement after 3.5 milliseconds. Using the distance the point of interest travels in the time between images, a velocity field can be determined. The same measurements were repeated for five trials of low bubble generation. When a high bubble generation is used the overabundance of bubbles prohibits the penetration of the laser through the bubble cloud and disallows any measurements to be made. During the generation of bubbles the tank was stirred to provide fluid motion. No Bubble Generation Undelayed image 3.5 millisecond delayed image Bubble Generation Undelayed image 3.5 millisecond delayed image This experiment verifies that MTV can be applied to a 2phase flow to measure velocity. The constraint on using this process is the overabundance of bubbles due to the lack of penetration with the laser. High Bubble Flow Class of 2009 Aeronautical and Mechanical Engineering B.S. REU Douglas Bohl, Ph.D.