Experimental details and spectral data and UV

advertisement

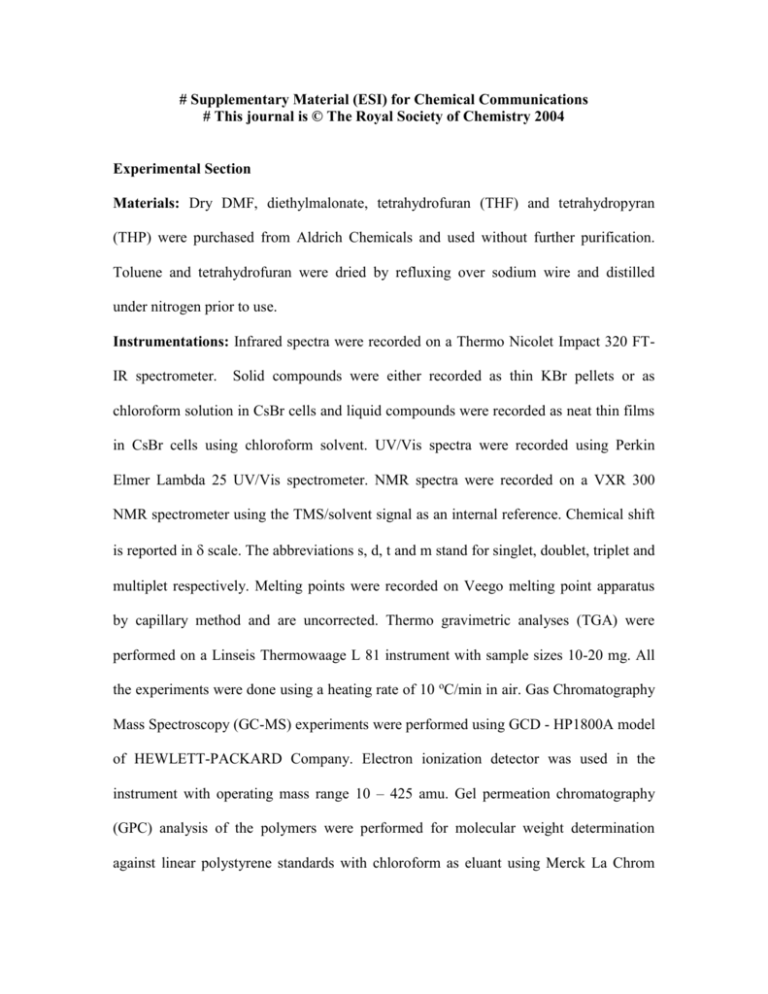

# Supplementary Material (ESI) for Chemical Communications # This journal is © The Royal Society of Chemistry 2004 Experimental Section Materials: Dry DMF, diethylmalonate, tetrahydrofuran (THF) and tetrahydropyran (THP) were purchased from Aldrich Chemicals and used without further purification. Toluene and tetrahydrofuran were dried by refluxing over sodium wire and distilled under nitrogen prior to use. Instrumentations: Infrared spectra were recorded on a Thermo Nicolet Impact 320 FTIR spectrometer. Solid compounds were either recorded as thin KBr pellets or as chloroform solution in CsBr cells and liquid compounds were recorded as neat thin films in CsBr cells using chloroform solvent. UV/Vis spectra were recorded using Perkin Elmer Lambda 25 UV/Vis spectrometer. NMR spectra were recorded on a VXR 300 NMR spectrometer using the TMS/solvent signal as an internal reference. Chemical shift is reported in scale. The abbreviations s, d, t and m stand for singlet, doublet, triplet and multiplet respectively. Melting points were recorded on Veego melting point apparatus by capillary method and are uncorrected. Thermo gravimetric analyses (TGA) were performed on a Linseis Thermowaage L 81 instrument with sample sizes 10-20 mg. All the experiments were done using a heating rate of 10 oC/min in air. Gas Chromatography Mass Spectroscopy (GC-MS) experiments were performed using GCD - HP1800A model of HEWLETT-PACKARD Company. Electron ionization detector was used in the instrument with operating mass range 10 – 425 amu. Gel permeation chromatography (GPC) analysis of the polymers were performed for molecular weight determination against linear polystyrene standards with chloroform as eluant using Merck La Chrom instrument attached with PL Gel 5 mixed c column and when the solvent was DMF Suprema 3000 column was used. Synthesis: Triethyl methanetricarboxylate (2): Magnesium turnings (1.25 g, 50.2 mmol), dry ethanol (5 mL) and CCl4 (0.5 mL) were taken in a dry 100 mL of three neck flask and it was heated at 80 oC for 6 h. To this was added a mixture of diethyl malonate (8 g, 50.2 mmol) and dry ethanol (14 mL) and stirred for 2 h. The reaction mixture was cooled in a water bath when crystals were formed. After this, dry THF (20 mL) was added drop wise to dissolve the solid formed and heated for 1 h at 80 oC. To this was then added ethyl chloroformate (5 mL, 50.2 mmol) in dry THF while keeping constant boiling and the heating was further continued for 1 h. The reddish colored reaction mixture so obtained was cooled to room temperature and poured into dilute acetic acid (4 mL acetic acid in 15 mL water). This was extracted with ethyl acetate and washed with brine. The organic layers were combined and dried over anhydrous Na2SO4 and concentrated to get yellow liquid. The unreacted diethyl malonate was then removed by vacuum distillation to get the pure product as a colorless liquid. Yield: 4.28 g (71%). mp: 29 oC. 1H NMR (300 MHz, CDCl3, δ ppm, J Hz): 1.31 (t, 9H, J = 7.14), 4.28 (q, 6H, J = 7.08), 4.41 (s, 1H). IR (CHCl3): 2883 (broad), 1748, 1471, 1290 cm-1. EI-MS (m/z): 233 (M++1). Triethyl sodio-methanetricarboxylate (3): Sodium ethoxide solution was prepared in a flame-dried 100 mL flask under a flow of argon gas using sodium metal (0.21 g, 9.14 mmol) and super-dry ethanol. In another flame dried flask was taken 2 (2.12 g, 9.14 mmol) in 20 mL of THF and cooled using an ice bath. To this was added sodium ethoxide drop-wise to get white sodium salt. The solvent was removed under reduced pressure and the salt was washed with dry petroleum ether and dried under high vacuum to get the product, which was non-hygroscopic in nature. Yield: 1.98 g (85%). mp: >250 oC (dec). 1H NMR (300 MHz, D2O, δ ppm, J Hz): 1.22 (t, 9H, J = 7.14), 4.08 (q, 6H, J = 7.08). IR (KBr): 2873, 1725, 1285 cm-1. EI-MS (m/z): 232 [(M++1)-Na+]. 4-bromobutyl acetate (4) and 5-Iodopentyl acetate (5) were synthesized according to the literature procedure.15 2-(4-Acetoxy-butyl)-2-ethoxycarbonyl-malonic acid diethyl ester (AB3-C4) and 2-(5acetoxy-pentyl)-2-ethoxycarbonyl-malonic acid diethyl ester (AB3-C5): In a dry 100 mL flask, 3 (1 g, 3.94 mmol) was taken in a mixture of dry toluene and dry DMF (1:1). To this was added 4-bromobutyl acetate, 4, (1.54 g, 7.87 mmol) or 5-iodopentyl acetate, 5, (2.02 g, 7.87 mmol) and heated at 90 oC for 20 h. The reaction mixture was then cooled and to this was added 15 mL of toluene. The organic layer was thoroughly washed first with water and then with brine solution. The organic layers were combined, dried over anhydrous Na2SO4 and concentrated to get yellowish liquid. It was then purified by column chromatography using 10% ethyl acetate in pet ether as eluant to get pure colorless liquid compounds AB3-C4 and AB3-C5. AB3-C4: Yield: 0.89 g (65%). bp: 205 oC. 1H NMR (300 MHz, CDCl3, δ ppm, J Hz): 1.28 (t, 9H, J = 7.86), 4.2 (q, 6H, J = 7.08), 4.1 (t, 2H, J = 6.59), 2.06 (s, 3H), 1.75-1.85 (m, 4H, J = 5.14), 1.95 (m, 2H, J = 7.81). 13C NMR (400 MHz, CDCl3, ppm): 171.38, 168.04, 13.84, 20.74, 23.84, 28.18, 28.26, 61.67, 64.23, 65.87. IR (CHCl3): 2960, 1740, 1441, 1367, 1239, 1041 cm-1. EI-MS (m/z): 232 (M+_ O O ) : Mc Lafferty rearrangement, 160 [(M++1) - (Mc Lafferty product, -OEt, -CO)]. AB3-C5: Yield: 1.7 g (60%). bp: 210 oC. 1H NMR (300 MHz, CDCl3, δ ppm, J Hz): 1.25 (t, 9H, J = 7.85), 4.25 (q, 6H, J = 6.58), 4.05 (t, 2H, J = 6.59), 2.04 (s, 3H), 1.35-1.45 (m, 4H, J = 5.95), 1.52 (m, 2H, J = 7.15), 1.65 (m, 2H, J = 7.41). 13 C NMR (400 MHz, CDCl3, ppm): 13.73, 20.75, 24.32, 26.07, 28.04, 32.94, 61.97, 64.30, 65.37, 167.01, 171.38. 232 (M+_ IR (CHCl3): O O ) 2980, 1740, 1368, 1243, 1110 cm-1. EI-MS (m/z): : Mc Lafferty rearrangement, 160 [(M++1) - (Mc Lafferty product, -OEt, -CO)]. 2-(4-Acetoxy-butyl)-malonic acid diethyl ester (AB2-C4) and 2-(5-acetoxy-pentyl)malonic acid diethyl ester (AB2-C5): In a flame dried three neck round bottom flask 1 (2 g, 12.5 mmol), 4-bromobutyl acetate, 4, (3.66 g, 18.7 mmol) or 5-iodopentyl acetate, 5, (4.8 g, 18.75 mmol) were taken in acetonitrile (20 mL) and stirred at room temperature for 2 min. To this was then added K2CO3 (9.49 g, 68.8 mmol) and refluxed for 36 h. After this, the mixture was filtered and the filtrate was concentrated to get yellow liquid. This was extracted with ethyl acetate, washed with water. The organic layers were combined and dried over Na2SO4 and purified by column chromatography using 5% ethyl acetate in pet ether as eluant. AB2-C4: Yield: 2.67 g (78%). bp: 250 oC. 1H NMR (300 MHz, CDCl3, ppm, J Hz): 1.26 (t, 6H, J = 7.87), 1.4 (m, 2H, J = 4.94), 1.65 (q, 2H, J = 7.05), 1.95 (q, 2H, J = 7.81), 2.04 (s, 3H), 3.32 (t, 1H, J = 7.50), 4.05 (t, 2H, J = 6.59), 4.2 (q, 4H, J = 7.08). 13C NMR (400 MHz, CDCl3, ppm): 14.01, 20.84, 23.77, 28.21, 28.27, 51.80, 61.26, 63.97, 169.27, 171.01. IR (CHCl3): 2981, 1738, 1462, 1369, 1243, 1148 cm-1. EI-MS (m/z): 160 (M+_ O ) O : Mc Lafferty rearrangement. AB2-C5: Yield: 2.52 g (70%). bp: 242 oC. 1H NMR (300 MHz, CDCl3, ppm, J Hz): 1.26 (t, 6H, J = 7.87), 1.32-1.40 (m, 4H, J = 5.94), 1.64 (q, 2H, J = 7.05), 1.9 (q, 2H, J = 7.81), 2.04 (s, 3H), 3.31 (t, 1H, J = 7.50), 4.05 (t, 2H, J = 6.59), 4.2 (q, 4H, J = 6.59). 13C NMR (400 MHz, CDCl3, ppm): 14.07, 20.95, 25.41, 26.94, 28.29, 32.34, 51.91, 61.31, 64.32, 169.48, 171.21. IR (CHCl3): 2934, 1737, 1464, 1369, 1241, 1155 cm-1. EI-MS (m/z): 160 (M+_ O O ) : Mc Lafferty rearrangement. Synthesis of Polymers: The monomer and the catalyst zinc acetate (100:1 molar ratio) were taken in a polymerization tube and were dried under high vacuum followed by the release of vacuum using dry argon. Then the tube was heated slowly to 190 °C under argon atmosphere using an oil bath and it was kept at this temperature for 8 h. The evolution of ethyl acetate was clearly visible after the sample was heated above the melt. Then the melt was evacuated at 0.2 mm/Hg for 2 h while maintaining the same temperature. After the reaction, the solution of the polymer in suitable polar solvent was precipitated into methanol. This was centrifuged, washed with methanol and dried in a vacuum oven to get pure polymer. Fig. 1. 13C NMR spectrum of monomer AB2-C4 Fig. 2. 400 MHz 13C NMR (APT) spectrum of polymer P(AB2-C4) Fig. 3 1H NMR spectrum of monomer AB2-C4 Fig. 4 1H NMR spectrum of polymer P(AB2-C4) Encapsulation experiments HBP ester Methyl orange in water Methyl orange in CHCl3 in CHCl3 Encapsulation P(AB2-C4) Methyl orange : N (dye) N N SO3Na Fig. 5. UV/Vis spectra of polymer [P(AB2-C4)], methyl orange (dye) and encapsulated polymer [P(AB2-C4)-dye] In a typical experiment five different concentration of dye [0.001M, 0.005M, 0.01M, 0.03M, 0.05M] was prepared and 2 mL of each dye solution was manually shaken for few minutes with 2 mL of 0.04 wt% solution of the polyester in chloroform. The aqueous layer was repeatedly washed with water. The washing process was again repeated after 24 h and then 1.5 mL of the organic layer was used for UV/Vis measurements.