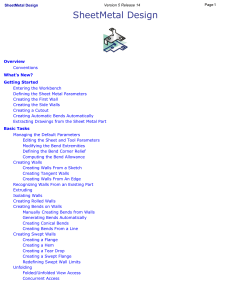

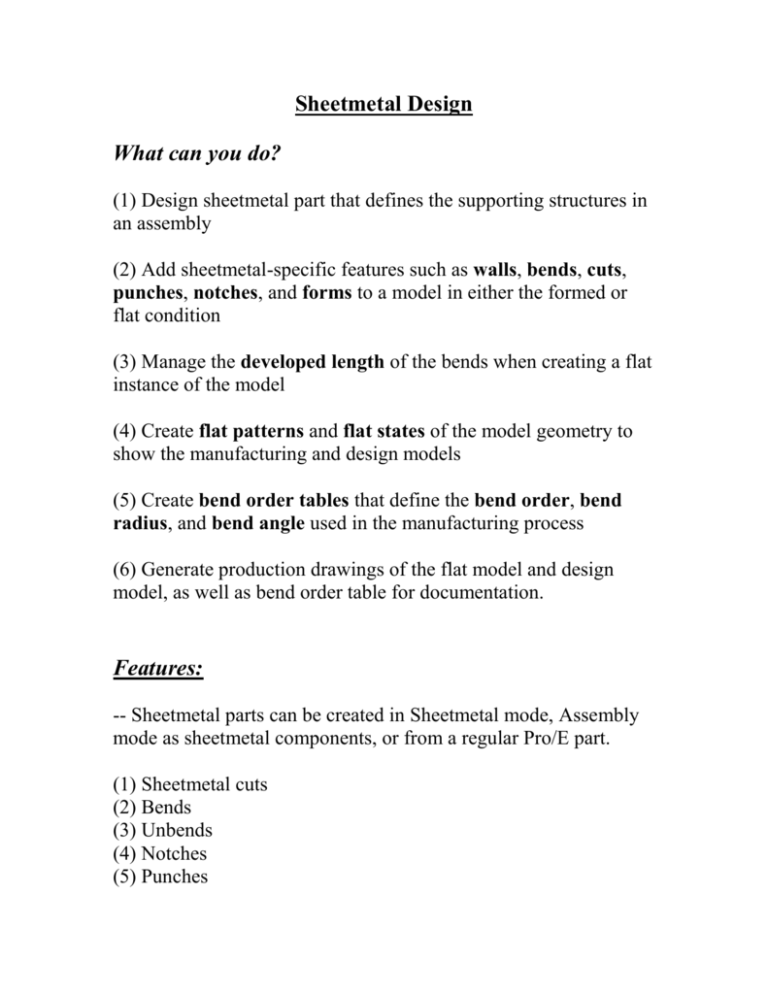

Sheetmetal Design

advertisement

Sheetmetal Design What can you do? (1) Design sheetmetal part that defines the supporting structures in an assembly (2) Add sheetmetal-specific features such as walls, bends, cuts, punches, notches, and forms to a model in either the formed or flat condition (3) Manage the developed length of the bends when creating a flat instance of the model (4) Create flat patterns and flat states of the model geometry to show the manufacturing and design models (5) Create bend order tables that define the bend order, bend radius, and bend angle used in the manufacturing process (6) Generate production drawings of the flat model and design model, as well as bend order table for documentation. Features: -- Sheetmetal parts can be created in Sheetmetal mode, Assembly mode as sheetmetal components, or from a regular Pro/E part. (1) Sheetmetal cuts (2) Bends (3) Unbends (4) Notches (5) Punches (6) Bend Backs (7) Forms (8) Walls Display: -- Sheetmetal part appears with green and white surfaces with side surfaces in between to define depth. -- Sheetmetal parts always have a constant thickness. Developed Length: -- Pro/E automatically compensates for stretching that occurs in the area of a bend by taking into account the thickness of the sheetmetal, the radius of the bend, the bend angle, and other material properties. Creating Walls: -- There are two types of walls: primary and secondary. Primary wall does not need another wall in order to exist. Secondary wall must be attached to another wall. Extrude – sketches the side section of the wall and extrudes to a specified depth. Revolve – sketch the side section of the wall and revolve it about a centerline. Blend – used parallel, rotational, or general blending feature forms to create a wall. Flat – sketch the boundaries of the wall in the Sketcher plane Offset -- offsets from an existing surface. Advanced – create a wall by using datum curves, multiple trajectories, etc. Create a box base: 1. <new file> - <Part> - <Sheetmetal> under sub-type 2. Enter file name as “box_base”, then click [OK]. 3. <Feature> - <Create> - <Wall> - <Extruded> - <Done> - <Both Sides> - <DONE> 4. Select datum plane FRONT as the sketching plane and datum plant TOP as the top reference. 5. sketch section as below. 6. Click <Sketch> - <Feature Tools> - <Tools> - [Thicken] 7. Click Flip of Okay. 8. Type <0.05> as thickness 9. Delete the exist radius dimensional, 10. Add a radius dimension to the thicken line 11. Modify the radius dimension to [0.08] 12. Extrude the blind depth of [8] 13. Save the model. Secondary Walls: Types of secondary walls: (1) Flat, no radius --- Sketch the boundaries of the wall attached to the selected edge. (create a parallel wall) (2) Extruded, No radius --- Sketch the side section of the wall that will be extruded along the attachment edge. (Need to sketch radius by yourself.) (3) Swept, No radius --- attach a wall to a nonlinear edge. (Need to sketch radius yourself.) (4) Flat, Use radius --- Sketch edges of wall and define bend radius. (5) Extruded, Use radius --- Sketch the side profile of the wall with a specific angle and then define the radius of bend. (6) Swept, Use radius --- Sketch the section of the wall then specify the radius.