Desensitising

advertisement

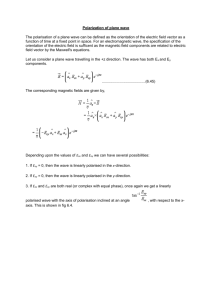

Desensitising a polarisation-based speckle interferometer for the polarisation direction of incoming scattered light P A A M Somers and N Bhattacharya Delft University of Technology, Lorentzweg 1, NL-2628 CJ Delft, the Netherlands P.A.A.M.Somers@TUDelft.nl; N.Bhattacharya@TUDelft.nl Abstract. A polarisation-based shearing speckle interferometer requires the incoming scattered light to have proper characteristics: for highest modulation the interfering beams should have the same intensity. Most surfaces scatter linearly polarised light randomly, providing equal intensities for the interfering beams on average. However, when a diffusely reflecting metallic surface is illuminated by a linearly polarised laser beam, the polarisation direction of the illuminating beam is retained to a large extent in the scattered light. As a result light entering the interferometer will not be randomly polarised, which may lead to low modulation due to unbalanced object and reference beams. Applying a polariser or a half wave plate in an appropriate direction to adjust polarisation direction or a combination of both can solve the problem. These solutions have disadvantages: loss of light and dependency on the orientation, which may require frequent adjustments to accommodate experimental conditions. An alternative solution that handles the problem effectively without these drawbacks is presented. It consists of a quarter wave plate oriented at 45°, positioned in front of the interferometer. It is shown that the unfavourable predominant polarisation state encountered with metallic surfaces will be converted into a favourable one, thereby obtaining well balanced object and reference beams, irrespective of the polarisation direction of the incoming light. 1. Introduction Polarisation based shearing speckle interferometers make use of a polarisation sensitive element to create two orthogonally polarised beams, one of them sheared, both originating from the object of interest. Within the interferometer the beams travel along a common optical path, outside the interferometer the optical path is almost common, giving this type of interferometer its intrinsic stability against disturbances. The beams interfere at a CCD sensor after passing an analyser. Possible implementations for the polarisation sensitive element are a Wollaston prism [1], a Savart plate [2], a bi-refringent wedge [3], or another beam splitting device such as a polarising beam splitter cube, used with two mirrors in a Michelson configuration [4]. One of the mirrors can be tilted to produce a variable shearing angle between the two beams. When the two speckle patterns interfere, the intensity I at a given pixel at the camera is given by the interference equation: I I o I r 2 I o I r cos , (1) where Io and Ir are the intensities of the object and reference beams and is phase difference between the two interfering beams at that particular location. The modulation term I M 2 Io Ir (2) reaches it highest value when the interfering beams have equal intensities. Modulation is zero if one or both of the interfering beams have zero intensity. 2. Problem description Since the intensity distributions of both interfering speckle patterns have their maximum at zero intensity, modulation is zero or low at many locations, resulting in poor signal to noise ratios. Low modulation can also occur due to unbalanced interfering beams, caused by unfavourable polarisation conditions. It is therefore desirable that the polarisation state of incoming light is well defined, for instance by taking care that incoming linear light is polarised at 45° upon entry. The interferometer acquires speckle patterns that are generated by a scattering object illuminated by a uniform beam. The polarisation state of the illuminating beam, often linearly polarised, is not preserved in the scattered field for many materials, producing randomly polarised beams that enter the interferometer. Although not ideal, this situation is acceptable when the average intensities of the interfering beams are the same. Metallic materials however show very low levels of depolarisation [5]. As a result the scattered field has a predominant polarisation state, depending on the polarisation of the illuminating beam. There are a number of measures that can be taken to solve this problem. First of all the polarisation state of the illumination could be altered, for instance by rotating the polarisation direction when it is linearly polarised, or by converting the light to circular. When using more than one illumination system, this should be done for every single system. A second approach could be a change of the polarisation state of the scattered light, just before it enters the interferometer. A polariser oriented at 45° ensures that a 1:1 relation between horizontal and vertical polarisation is established, at the expense of losses for other polarisation directions, in particular for -45°. In addition there are absorption losses when using a polariser. Another solution without substantial absorption losses is an adjustable half wave plate that can be given the best position to obtain mainly 45° polarised light, when the depolarising properties of the object are not sufficient to provide random polarisation. This approach requires re-adjustment of the half wave plate whenever the polarisation state of the scattered light makes it necessary. In addition it is desirable to have available some measurement system that can determine the optimum setting during adjustments. 3. Polarisation state conversion We have chosen another way of conditioning the light before it enters the interferometer that does not require re-adjustment and associated measurements, thus simplifying the operational use of the interferometer. Although for this system there are also polarisation states that are unfavourable after conversion, this solution provides considerable improvements in most practical situations, in particular when the scattered light coming from an object that is illuminated by a linearly polarised beam is not fully depolarised, and the light has largely linear properties in a possibly unfavourable orientation. A perfectly scattering object illuminated by a uniform beam with linear polarisation reflects light in all directions with all polarisation states: for coherent illumination the polarisation state of the scattered light is random. Coherent light with random polarisation can be described as the combination of a horizontally and a vertically polarised wave, both with arbitrary amplitude, with an arbitrary constant phase difference between them. An object that not fully depolarises the incoming light preserves its polarisation state to some extent: that state becomes predominant in the scattered light, which can be unfavourable for a polarisationbased interferometer. The task of a device that must reduce the dependency of the interferometer on the polarisation direction is then to convert the unfavourable predominant polarisation state into a favourable one. The unfavourable polarisation state for a system with vertically polarised illumination used on a metallic scattering surface is vertical. This unfavourable state becomes the favourable one if the light is converted to circular. A quarter wave plate oriented at 45° in front of the interferometer fulfills the task. Linear light in arbitrary direction will be converted to elliptical light by the quarter wave plate. Special cases of the ellipse are circles for vertical or horizontal input, or straight lines for linear input at -45° or +45°. The axis of the ellipse is oriented at 45°, ensuring that the split-up after the polarising beam splitter will be 1:1 for incoming linear light in any direction. The plate will not affect the most favourable input state without conversion: linear light at 45° will remain linear. Circular states however will be converted to either vertical or horizontal, which implies a degradation for these states. Other states, in general all elliptical states, will be less affected: since elliptical light can be considered as a combination of linear light and circular light, only the circular portion gets the unfavourable vertical or horizontal state after passing the quarter wave plate. The linear portion is converted to the ideal circular state. 4. Experimental Experiments were carried out to evaluate the properties of the interferometer before and after modifying it by adding a quarter wave plate oriented at 45° in front of it. An overview of the interferometer is presented in figure 1. Light entering the interferometer is split by polarising beam splitting cube PBC1. Horizontal light is transmitted to fixed mirror M2, and reflected back towards the beam splitter. A quarter wave plate oriented at 45° attached to the beam splitter takes care of conversion to vertical light, that is reflected to the exit of the cube. Similarly vertical light entering the interferometer is reflected towards shearing mirror M1, reflected back and converted to horizontal by another quarter wave plate. Mirror M1 is slightly tilted to obtain a sheared image. At the exit now two orthogonally polarised beams propagate into a channel splitter section that splits the beam pair into two channels to allow for a phase step in one of the two channels. As a result two speckle interferograms are available side by side on a single CCD camera, with a mutual phase step of /2. The interferometer and its alignment system are described in more detail elsewhere [4,6]. First of all a measurement was carried out on a metallic object demonstrating the problem. The object, coated by a thin primer layer, was illuminated by vertically polarised light. The polarisation state was measured using an analyser in different angular positions. Although coated, the metallic object still scatters light with predominant vertical polarisation as figure 2 clearly shows. A matt white painted object also illuminated by vertical light shows almost no dependency on analyser angle. L1 Object CCD Left image Right image Intermediate image L3 Piezo controls L2 BC1 BC1 M4 M1 PBC2 ¼ wave plate Phase stepper PBC1 M2 M3 P1 Beam splitter Beam combiner Shearing unit Figure 1 Polarisation-based shearing speckle interferometer. Trace A Trace B Figure 2 Intensity of a scattered beam as a function of analyser angle. Trace A: light scattered by a metallic surface covered with a thin primer layer. Trace B: light scattered by a surface covered with white matt paint. Another result is shown in figure 3. Here the interferometer itself is used as measuring device. Either mirror M1 or M2 is blocked and the average intensity of the speckle pattern on the CCD is measured as a function of the orientation of a half wave plate, positioned in front of the interferometer. The tracks for mirror M1 and M2 presented in figure 3 show large fluctuations, due to the mainly vertical polarisation of light scattered by the metallic object. Figure 3. Intensity of a beam scattered by a metallic object, measured by the interferometer with either mirror M1 or M2 blocked, as a function of the polarisation direction of incoming light. Polarisation is changed by adjusting the orientation of a half wave plate in front of the interferometer. After insertion of a quarter wave plate oriented at 45°, results have considerably improved, as figure 4 shows. Again the interferometer is used to measure average intensities as a function of the orientation of the half wave plate, when either one of the mirrors M1, M2 is blocked. Some dependency remains, possibly caused by imperfect alignment. Figure 4 Intensity of a beam scattered by a metallic object, measured by the interferometer with either mirror M1 or M2 blocked, as a function of the polarisation direction of incoming light. Polarisation is changed by adjusting the orientation of a half wave plate in front of the interferometer. The interferometer is modified by adding a quarter wave plate oriented at 45° in front of it. Finally some experiments have been carried out on a component with an artificial defect, before and after the modification. The component, a Fokker 100 speed brake containing an artificial defect was thermally loaded to induce local deformation at the defect area. The object was observed with the interferometer during cooling down, using vertical shearing, and the intermediate phase differences for a series of measurement intervals were accumulated to obtain an unwrapped final phase difference map. Figure 5 shows the results. An estimate of the improvement was obtained by calculating the ratio between measured maximum phase difference over a vertical cross-section at the defect area and the average noise level for that cross-section. Before modification this ratio was 5.83, after adding the quarter wave plate it was 7.39. (a) (b) Figure 5 Indication of a defect in a Fokker 100 airbrake, after thermal loading. Results are shown before (a) and after (b) modifying the interferometer. 5. Conclusions A polarisation-based shearing speckle interferometer has been modified in order to convert the predominant unfavourable vertical polarisation state encountered when a metallic scattering surface is illuminated by a vertically polarised beam. As a result linear light in any direction is converted to circular, providing well balanced object and reference beams for these cases. Average modulation has thus been increased, yielding better S/N ratios for measurement results. Acknowledgements This research was supported by the Technology Foundation STW, applied science division of NWO and the technology program of the Ministry of Economic Affairs. References [1] M. Francon, S. Mallick, "Polarization Interferometers", Wiley-Intersciense, London, 1971. [2] S. Debrus, "Speckle shearing interferometer using a Savart plate", Opt. Commun., 20 (1977), pp. 257-261. [3] S. Nakadate, T. Yatagai, and H. Saito, "Digital speckle-pattern shearing interferometry", Applied. Optics. 19, pp. 4241-4246 (1980). [4] Peter A.A.M. Somers and Hedser van Brug, "A single camera, dual image real-timephase-stepped shearing speckle interferometer", Proceedings Fringe 2001, pp. 573580, Wolfgang Osten, Werner Jüptner, eds., Elsevier, 2001. [5] M. Adams, K.D. Hinsch, F. Lange, K. Wolff, "Polarization effects in speckle correlation metrology", Opt. Engineering 36(8) pp. 2225-2228 (August 1997). [6] Peter A.A.M. Somers, Nandini Bhattacharya, "Maintaining sub-pixel alignment for a single camera two-bucket shearing speckle interferometer", Journal of Optics A: Pure and Applied Optics No 7, pp. S385-S391 (2005).