Dislocation - Concordia University

advertisement

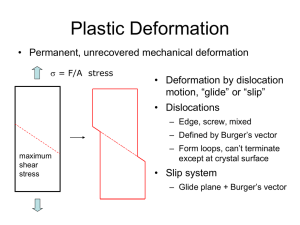

WHAT YOU ALWAYS WANTED TO ASK ABOUT DISLOCATIONS, BUT NOW YOU CAN KNOW WITHOUT BEING AFRAID What you never wanted to know about dislocations but are afraid the examiner may ask Hugh McQueen, Prof. Emeritus, Mechanical Engineering, Concordia University, Montreal LIST OF QUESTIONS EVIDENCE FOR DISLOCATIONS ?? What are dislocations? What do dislocations do? What primary characteristics of matter underlie dislocations? Is there a commonly observed microscopic behavior associated with plastic straining? Do such planes have a common characteristic that is independent of crystal structure? What is the optical microscopic evidence for slip? How does X-ray evidence support the slip mechanism? What stress condition causes slip to take place? Is the critical stress consistent with the entire plane slipping simultaneously? Is there optical microscopic evidence for dislocations? What is the clearest microscopic evidence for dislocations? Answers,pages 14, 15 Page 2 LATTICE GEOMETRIES OF DISLOCATIONS ?? What is the geometry of edge dislocation? How did the concept arise? What is the geometry of the screw dislocation? Are there other kinds of dislocation? Are there other kinds of dislocation? Can the same dislocation have both edge and screw orientations? Can a dislocation form a closed loop? What is the stress field associated with the screw dislocation? What is the stress field associated with the edge dislocation? Are the stress fields compatible in an L shaped dislocation? What are the migration and action of a) edge and b) screw dislocations moving under a stress? Answers,pages 16, 17 Page 3 BURGERS VECTORS ?? What is the Burgers vector of a dislocation? How is the Burgers vector distinct for edge and screw dislocations? How is the Burgers circuit used to define the Burgers vector b ? How is the Burgers vector related to the shear and the glide direction? What is the energy related to a dislocation? How is the Burgers vector related to the simple cubic crystal lattice? How is the Burgers vector related to the face centered cubic (FCC) crystal lattice? How is the Burgers vector related to the body centered cubic (BCC) crystal structure? Why are dislocations illustrated in simple cubic instead of a lattice in which metals crystallize? Answers, pages 18,19 Page 4 ANNIHILATION OF DISLOCATIONS…??? What are the relative Burgers vectors of two parallel edge dislocations one with extra half-plane above the slip plane and the other with it below? How can edge dislocations annihilate? What are the relative Burgers vectors of two parallel screw dislocations one with a left hand twist and one with a right hand twist? What happens when two parallel screw dislocations with opposite Burgers vector meet? Do opposite parallel dislocations have an effect on each other at a distance? What is the interaction of parallel edge and screw dislocations? What is the interaction of two dislocations with the same Burgers vectors? Answers, pages 20, 21 *RECOVERY Page 5 LOOPS OF DISLOCATIONS ??? What is the Burgers vector of a dislocation L shaped in the slip plane, with edge and screw components? What is the Burgers vector of a square loop of dislocation? In a single dislocation loop what are the interaction of opposite parallel sides? What happens when two such square loops are near each other in the same slip plane? In a general dislocation loop of irregular shape, how are the characters and b related? What is the situation when a segment on a slip plane continues as segment that is not on any slip plane? What configuration is achieved if the segment leaving the slip plane is on another slip plane perpendicular to it (as in simple cubic)? Are there conditions under which both segments could move? How can this configuration be developed into slip in a tube known as pencil glide? Is it possible to have a square dislocation loop, which has all edge components? How can it be created? *PRISMATIC LOOP Is it possible to have a square dislocation loop, which has all screw components? How can it be formed? Answers, pages 22, 23 Page 6 DISLOCATIONS ONLY IN CRYSTALS ??? Can dislocations be found in non-crystalline materials? How do dislocations get into a crystal? How does a stationary dislocation affect the macroscopic character of the crystal? Can a dislocation be considered as a defect confined to a few atomic distances in any plane normal to it? Can a dislocation line end inside a crystal? * b into node is zero To what extent is the geometrically visualized core of the dislocation extended? Are dislocations spread out more on the slip plane than other directions and is this different for edge and screw dislocations? Are all dislocations in a crystal mobile, that is, able to glide? Answers, pages 24, 25 Page 7 GLIDE IN RESPONSE TO STRESS ??? How does a shear stress on a slip plane affect a dislocation? *FORCE PER UNIT LENGTH How does a given shear stress affect a dislocation L shaped in the slip plane? How can the sense of direction of motion be determined? *FATIGUE How does a uniform shear stress on a plane affect a dislocation loop? What is the effect of stress on a dislocation that has a sessile segment that is not on the slip plane? Does a dislocation require a critical level of stress to move? Is the Peierls stress affected by temperature? Is the Peierls stress affected by impurities? What is the Cottrell interaction of dislocation with atoms of different sizes? *SOLUTE STRENGTHENING Why is a stress required to lengthen the dislocation? Answers, pages 26-28 Page 9 MULTIPLICATION OF DISLOCATIONS How does plastic strain affect the flow stress? What is the most commonly observed behavior of dislocations during strain hardening? How is the density of dislocations reported and measured? How does the dislocation density increase during straining? What is the nature of a Frank-Read source? How do the two lobes or spirals of the Frank-Read source pinch off? What is the effect on the dislocation array of the Frank-Read source? Is the Frank Read source more significant then the single ended? What happens if there are two Frank Read sources on the same slip plane? Do all Frank Read sources start to operate at the same stress? What happens when the loops reach the free surface of a single crystal? Answers, pages 29-31 Page 10 YIELDING AND STRAIN HARDENING ??? How is the operation of Frank-Read sources related to macroscopic behavior? *YIELDING AND SLIP LINES How is the operation of Frank Read sources related to slip lines optically visible? How much strain is produced by the glide of the dislocations? What happens in a polycrystal when the source is in a grain enclosed on all sides by other grains? What is the effect of a pile up of loops at grain boundary? *PILE UP MODEL OF STRAIN HARDENING Answers, page 32 Page 11 DISLOCATIONS AND THERMAL VIBRATIONS ??? Do the vibration of the atoms aid dislocation motion? *THERMAL ACTIVATION What happens to the work done as the dislocation moves under stress? *ENERGY DISSIPATION Answers, page 33 Page 12 CROSS-SLIP OF SCREW DISLOCATIONS ??? Can a screw dislocation change slip planes? *CROSS-SLIP Does cross slip become more frequent at higher temperature? Does the whole new segment need to cross slip at once? What is evidence for such cross slip? *WAVY GLIDE What is the result of screw segment of a loop undergoing repeated cross slips? Answers, page 34 Page 13 CLIMB OF EDGE DISLOCATIONS How can edge dislocations move in directions not in the slip plane? How does the climb process proceed? What are the relative rates of climb and glide? How is this behavior described in terms of vacancy dynamics? *VACANCY SOURCES AND SINKS Can stress play a role in edge dislocation climb? *CREEP AND RECOVERY How does climb contribute to the recovery of a pile up? What is the result of the recovery of a pile up? What is a tilt wall and what happens as a result of climb? How does climb of opposite dislocations lead to annihilation? What happens when a dislocation loop is subjected to climb conditions? Answers, page 35-37 Answers,page 14 EVIDENCE FOR DISLOCATIONS What are dislocations? A dislocation is an imperfection or distortion in a crystal that is a continuous line. Later exchanges will produce more information of geometry and intersections. What do dislocations do? When a stress is applied to the material, the dislocations move to cause plastic deformation with ease. Dislocation motion affects the mechanical properties in many ways that will be examined. What primary characteristics of matter underly dislocations? Only solid materials that are crystalline may contain dislocations that are vital for conferring ductility; however the extent may be very limited depending on composition and loading conditions. Is there a commonly observed microscopic behavior associated with plastic straining? Each crystal appears to deform by slipping on parallel planes (1000 atoms apart). On large single crystals such steps are visible to the naked eye, being somewhat like the shear of a deck of cads. Such planes are a specific family in the crystal structure and have multiple orientations dependent on the symmetry of the crystal; some crystal structures may have several such families. Do such planes have common characteristics that are independent of crystal structure? Planes of atoms on each side of the plane of slip are found to be the most widely separated in the crystal and hence having the greatest density of atoms. The wide separation provides the widest latitude for the distortion of atom-to-atom bonds. What is the optical microscopic evidence for slip? The strongest is the parallel slip steps that appear on the pre-polished face of a polycrystal specimen after modest deformation; there are usually several families per grain and do not cross the grain boundaries. If a deformed sample is sectioned, polished and etched suitably, groups of parallel markings similar to the above appear. As confirmed much later, this arises due to the more rapid attack at highenergy dislocations on the slip plane, somewhat like the deeper etching at grain boundaries. Answers, page 15 How does X-ray evidence support the slip mechanism? As strain rises, the deformation pattern remains similar indicating that the crystal structure is not severely altered but changes in a manner that gives evidence at an increasing density of distortion with high strain (stress) fields. What stress condition causes slip to take place? Slip in a specific batch of metal occurs when the resolved shear stress on the slip plane reaches a critical value; however it is strongly dependent on the purity. Is the critical stress consistent with the entire plane slipping simultaneously? No, the magnitude of the shear stress is only about one thousandth of that required to break all the bonds crossing the plane simultaneously. This points to an imperfection, which permits slipping of a limited region that spreads progressively (illustrated in Lecture 3 of the film: “ The Analogy of the Ripple in the Rug”). Is there optical microscopic evidence for dislocations? Yes, at low strains in some materials, the slip markings can be resolved into individual pits clearly lying on planes. When a slight increment of strain is applied and light etching is repeated, new pits are formed on the same planes and old ones do not grow, thus indicating that the defects have moved. Deep etching confirms that pits are associated with defects almost normal to the surface. What is the clearest microscopic evidence for dislocations? In transmission electron microscopy, electrons passing through a thin metal foil are deflected by the elastic distortion around the dislocations. Individual dislocations appear as dark lines, sometimes lying on slip planes but sometimes in tangles. It was possible to apply a stress in the microscope and observe the dislocations moving on parallel planes. This is illustrated in Lecture 2 and 15. Answers,page 16 LATTICE GEOMETRIES OF DISLOCATIONS What is the geometry of edge dislocation? How did the concept arise? Dislocation geometry was developed from imagining a ripple whose motion would cause a relative displacement across a crystal plane. The edge type is the line in the slip plane defined by the intersection of the slip plane with an extra half plane, which extends above or below the slip plane. A single slip plane arbitrarily illustrated as horizontal. This configuration of atoms has been imaged in high-resolution electron microscopy. This is illustrated in Lectures 1 and 4. What is the geometry of the screw dislocation? It is a line in the slip plane created by a shear in the slip plane on only one side of the line. It causes the planes normal to the dislocation to become a helicoid. The helicoid or screw may have a right or left hand twist. Such helicoidal geometry is observed when the dislocation serves as an axis of crystal growth, where atoms are added. Some parking garages are built as helicoids (entire floor is a ramp) with a vertical axis and the slip plane parallel to the entering direction; the parking helicoid usual ends abruptly in a line above the entrance. This type is illustrated in Lecture 5. Are there other kinds of dislocation? Yes, mixed dislocations, which are in between edge and screw orientations and are actually very common. Their geometry is difficult to visualize. They are found along a winding dislocation line in regions when it is not in the edge or screw orientation; such dislocations are created in crystals as they solidify. Can the same dislocation have both edge and screw orientations? Yes, a dislocation L-shaped on the slip plane can have one segment in the edge orientation and the perpendicular segment in the screw orientation. Essentially the helicoidal layer of the screw terminates along the slip plane becoming the extra half plane of the edge segment. If there were an extended curved connection between the edge and screw segments, it would be a mixed segment. (If horizontal floors were constructed above the helicoidal garage, the edge of the parking ramp represents the horizontal edge dislocation. This is illustrated in Lecture 5.7. Answer.page17 Can a dislocation form a closed loop? Yes, it could consist of four segments alternating from edge to screw. The opposite edges would have extra half planes above and below the slip planes and the opposite screw would have right and left twists. If the corners become curved, they would become mixed dislocation. If the loop took on a circular shape it would be almost entirely mixed with very short edge and screw segments. This is illustrated in Lecture 16. What is the stress field associated with the screw dislocation? The dislocation is a compression-tension ripple across the slip plane and normal to the dislocation and the extra half plane; the compression is on the side of the slip plane with the extra half plane and normal to it. This constitutes an elastic dipole and has a field and behavior somewhat like an electrical dipole. There is shear component on the slip plane. What is the stress field associated with the edge dislocation? It is a shear stress field parallel to the dislocation line. Are the stress fields compatible in an L shaped dislocation? Yes, the narrow shear components of the edge between the compression above and the tension below the slip plane, all being normal to the extra half plane, become the extended shear component parallel to the screw segment. What are the migration and action of a) edge and b) screw dislocations moving under a stress? When the edge dislocation moves, i.e. glides, in the slip plane normal to its length, it accomplishes a shear equal in thickness to the extra half plane. When the screw dislocation moves normal to its length, thus motion normal to the glide of an edge; it produces a shear parallel to its length. This is illustrated in Lectures 1, 4 and 5. Answers, page 18 BURGERS VECTORS What is the Burgers vector of a dislocation? This vector represents the direction and magnitude of the ripple, i.e., of the shear produced by the dislocation. How is the Burgers vector distinct for edge and screw dislocations? The Burgers vector of an edge is normal to it and of screw is parallel to it. For an L shaped dislocation the two segments would have the same b . This is illustrated in Lecture 6. How is the Burgers circuit used to define the Burgers vector b ? The circuit in a plane normal to a dislocation proceeds along lattice directions in a sense given by the rotation of a right hand screw advancing along the positive direction that is arbitrarily assigned to the dislocation line. The circuit must precede an equal number of atomic spacings in the forward and reverse senses of any one-lattice direction. If the circuit does enclose a dislocation, it does not close but has a gap equal to the elastic distortion. For an edge dislocation, it is in the plane of the circuit (equaling the extra half plane thickness), thus perpendicular to the line. For a screw dislocation, it is normal to the circuit plane (equaling the pitch of the helicoid) and thus parallel to the line. This is illustrated in Lecture 6. How is the Burgers vector related to the shear and the glide direction: a) of an edge dislocation and b) of a screw dislocation? a) The edge dislocation glides in a direction parallel to b and produces a shear equal to b as expected of a compression-tension ripple. b) The screw dislocation glides in a direction normal to b and produces a shear equal to b as expected from a shear ripple. This is illustrated in Lecture 6. What is the energy related to a dislocation? As an elastic defect the dislocation has a strain field proportional to b , thus to the strain it can create and a stress field proportional to G b where G is the shear modulus. The energy per unit length is thus proportional to their product that is G b2. Answer, page 19 How is the Burgers vector related to the simple cubic crystal lattice? The b is the shortest repeat distance in the crystal so that its energy is as low as possible. The shortest distance is twice the radius of an atom. In simple cubic this direction is a cube edge. There are thus possibly 3 perpendicular Burger vectors. The planes that are further apart and have highest density of packing are the cube faces and these are the slip planes. How is the Burgers vector related to the face centered cubic (FCC) crystal lattice? In FCC, there are atoms on the cube corners and in the center of the faces; the atoms touch along the face diagonals. The b are thus half the length of the face diagonals; two in each cube face are at right angles to each other. However the three meeting at one corner are at 60o. Two of these are coplanar on the octahedral plane that is normal to a body diagonal and contains a third face diagonal. All the atoms along the these face diagonals are touching confirming that this is a close packed plane; each atom has 6 neighbors. These planes are furthest apart and are the slip planes observed experimentally. They are at 70.5o to each other. How is the Burgers vector related to the body centered cubic (BCC) crystal structure? In BCC, there are atoms on the cube corners and in the center of the cube; the atoms touch along the body diagonals. The b are thus half the length of the cube diagonals and there are six of them. Two cube diagonals are at 70.5o to each other, in each diagonal plane halving the cube; there are 6 such planes in pairs at right angles but at 60o to the others. These and other slip planes are observed experimentally. The half planes normal to b have two layers of atoms; so like FCC, they are not easily visualized as for BCC. Why are dislocations illustrated in simple cubic instead of a lattice in which metals crystallize? The dislocation geometry is very clear in simple cubic because the extra half-plane (normal to the slip cube face and to Burgers vector cube edge) is parallel to a cube face. It is thus clearly visible in a side view, i.e. the plane normal to dislocation line (see Lecture 1) and also in the top view, i.e. the plane parallel to the slip plane (see Lecture 3). In FCC, planes normal to b are composed of 2 layers of atoms spread apart in a direction normal to b so are difficult to visualize. In BCC, the same problem arises. Similar problems arise with the screw dislocation since the pitch of the helicoid involves two atomic layers offset laterally. Answers,page 20 ANNIHILATION OF DISLOCATIONS What are the relative Burgers vectors of two parallel edge dislocations one with extra half-plane above the slip plane and the other with it below? To compare parallel dislocations, the directions must be assigned in the same sense. When the Burgers circuits are conducted, the vectors of the two dislocations will be found to be the opposite of each other, being normal to the dislocation lines. How can edge dislocations annihilate? If two parallel edge dislocations with opposite b move into coincidence, the sum of the b will be zero; a Burgers circuit about both of them just before they meet would confirm this (the previous gaps in the circuits of each dislocations would cancel. Moreover from examination of the structure, the extra-half planes above and below the slip plane form a complete plane so that the geometry indicates the absence of a dislocation. This is illustrated in Lecture 8.1. What are the relative Burgers vectors of two parallel screw dislocations one with a left hand twist and one with a right hand twist? With the dislocation directions having the same sense, the Burgers circuits would indicate that the b are opposites and parallel to the dislocation lines. What happens when two parallel screw dislocations with opposite Burgers vector meet? The b of the combined dislocation would equal the sum of the two b which is zero. So the dislocations have annihilated each other. This is illustrated in Lecture 8.3. Do opposite parallel dislocations have an effect on each other at a distance? Yes, they attract each other since glide moving them together would reduce the energy. Moreover, the extended strain fields would begin to cancel even before annihilation. Edge dislocations of opposite sign are elastic dipoles of opposite sign and would attract like analogous electrical dipoles. When the opposite dislocations are not on the same slip plane they attract but can only move under special circumstances. The movement of dislocations toward each other and their final annihilation is an important mechanism of recovery. Answers page 21 What is the interaction of parallel edge and screw dislocations? The Burgers vectors are normal to each other. If they combined to give a mixed dislocation with the vectorially added b , the energy would be the same as the dislocations individually so no attraction. What is the interaction of two dislocation with the same Burgers vectors? If they were to coincide, the Burgers vector would twice as long so that the energy would be four times as large. Such dislocations would repel each other. Answers, page 22 LOOPS OF DISLOCATIONS What is the Burgers vector of a dislocation L shaped in the slip plane, with edge and screw components? As explained earlier (-) the geometry of the two segments is compatible. When the direction of the dislocation is assigned as continuous the two segments have the same b . (See Lecture 5.7). What is the Burgers vector of a square loop of dislocation? The dislocation must be assigned the same sign throughout so the Burgers vector would be the same around the entire loop, that consists of four L-shaped configurations connected. In a single dislocation loop what are the interaction of opposite parallel sides? In analysis of the opposite parallel sides in isolation, they would have opposite directions but the same b . If the direction of one was reversed so both become parallel, they have opposite b so that they would annihilate, thus eliminating the loop. In the absence of an external force, the attraction of opposite sides would eliminate the loop; however the presence of impurities may hinder such glide. What happens when two such square loops are near each other in the same slip plane? If the positive directions are arranged in identical ways, that is traverses around the loops either both clockwise or both counter clockwise; they would have the same Burgers vector. The two parallel segments that lie near each would be running in opposite senses for analysis of these two segments in isolation. If for common analysis the direction of one is reversed, the two segments would have opposite dislocations. These would then glide together and annihilate each other leaving a single loop with the combined area of the previous two. In a general dislocation loop of irregular shape, how are the characters and b related? In analyzing a loop, the direction is continuous around it and so the Burgers vector is the same all around. The segments that are normal to b are edge type and those parallel have screw character. If the two opposite parallel segments are analyzed they must be considered in the same sense. When one line is reversed in direction, its b is reversed so the dislocations are opposite of each other. If b is normal to lines, they are edge with the extra half plane for one above the slip plane and for the other below it. If b is parallel to the lines, the segments are screw one being right-hand twist and the other left hand. Answers, page 23 What is the situation when a segment on a slip plane continues as segment not on any slip plane? The segment, which is not on any slip plane is sessile and unable to move. The part on the slip plane can glide (said to be mobile) but not at the connection to the sessile part. The sessile is said to be pining the mobile segment. This is illustrated in Lecture 12. …… What configuration is achieved if the segment leaving the slip plane is on another slip plane perpendicular to it (as in simple cubic)? In the special case that the first segment is edge, the segment at right angles is also edge and the geometrical configuration is an extra quarter-plane (or a three quarter plane or the opposite b ). If one segment were screw then the other would be edge and they would be an L-shaped dislocation in another slip plane. Are there conditions under which both segments could move? Yes, if the same shear stress exists on both planes, then they could glide maintaining the character of the L-shape. One could think of a block in one corner of a crystal sliding relative to an L-shaped part. This is illustrated in Lecture 11. How can this configuration be developed into slip in a tube known as pencil glide? If the dislocation consisted of 4 perpendicular segments forming a square loop normal to the Burgers vector then this could move creating a square tube slip surface; this is called Pencil glide and is equivalent to punching a depression in the crystal. Under other circumstances the series of edge segments could glide on a corrugated surface. In face centered cubic, the slip planes would be at 70.5 o to each other, so the slip would be like that of a small group of hexagonal pencils in large bundle. Is it possible to have a square dislocation loop with all edge components? How can it be created? Yes, a square dislocation loop can have its b normal to the plane of the loop. These would be on two sets of perpendicular slip planes. The loop could have the externally half plane on the outside and have been produced by condensation of vacancies. It is called a prismatic loop. If the extra half plane were on the inside it could have been produced by a punching force on cube face. Is it possible to have a square dislocation loop, with all screw components? How can it be formed? No, not an isolated loop because b must be parallel to the sides of the loop. However if a set of parallel edge dislocations were superimposed on a set of parallel screw dislocations with the same b . these would react at the nodes to produce a single parallel set of mixed dislocations at 45o. Answers,page 24 DISLOCATIONS ONLY IN CRYSTALS Can dislocations be found in non-crystalline materials? No, from the proceeding, it can be seen that the dislocation has defined characteristics that differ with orientation along its length but are consistent with its Burgers vector that is constant and is a repeat distance of atoms throughout the lattice. The non-crystalline materials have no long-range order and unable to define a uniform repeat vector. How do dislocations get into a crystal? They form during growth in local regions of the crystal due to thermal stresses. Where they intersect the growth surface they are combined into the enlarging crystal. In a glassy material there is no long-range order to perpetuate the defect. The in-grown dislocations may have segments that do not lie on the common slip planes. How does a stationary dislocation affect the macroscopic character of the crystal? A slip surface can be assigned so that is subtended by the dislocation and by the surface of the crystal. The material on one side of the dislocation has undergone slip equal to the Burgers vector whereas the material on the other has not. In the case of a dislocation loop, the enclosed region can be defined as having slipped. Of course the region outside the loop may be considered to have slipped in the opposite direction. Can a dislocation be considered as a defect confined to a few atomic distances in any plane normal to it? No, the dislocation extends throughout the crystal (a Burgers circuit around it always has the same gap) although its intensity does decline with distance (the ratio of the gap length to circuit diameter decreases). The screw field has components parallel to the dislocation line. Answers ,page 25 Can a dislocation line end inside a crystal? No, if one were to imagine that it ended, then the stress field component in the direction parallel to the dislocations line would have to be negated by another stress field that would constitute a new dislocations continuing the hypothetically terminated one. However, two dislocations could meet along a limited length and combine into a third dislocation; such a condition means that the sum of the Burgers vectors with dislocation directions running into the node is zero. To what extent is the geometrically visualized core of the dislocation extended? The degree of extension depends strongly on the bonding characteristics of the crystal. In general, metallic bonding permits a rather large extensions compared to that permitted by a directional covalent bond or by an ionic bond between ions of different charges. Metallic bonding also facilitates mixed dislocations whereas other bonding may have a strong Peierls force that tends to maintain the dislocation as long segments joined by short screw segments. Are dislocations spread out more on the slip plane than other directions and is this different for edge and screw dislocations? Yes, the dislocations can be extended more on the slip plane, which is active. This effect is notable for a screw dislocation, which may have several possible slip planes, which meet the condition of containing the dislocation line and Burgers vector. Are all dislocations in a crystal mobile that is able to glide? No, there are segments of dislocations that are not mobile; this is classed as sessile. A dislocation segment can potentially slip on a plane defined by the line and the Burgers vector. It cannot glide unless that plane is one of the slip planes permitted by the lattice as observed experimentally. Some segments along a curved dislocation may be mobile and others sessile. Answers, page 26 GLIDE IN RESPONSE TO STRESS How does a shear stress on a slip plane affect a dislocation? The shear stress results in a force per unit length in the slip plane; it is the vector dot product of b and the vector component of shear stress in the plane (or the product of b and the component of shear stress parallel to it). The force per unit length is always normal to the dislocation along its length regardless of how it curves in that slip plane. In the slip plane, such a force per unit length is the two-dimensional equivalent of a pressure. Motion of only a few dislocations does not constitute yielding. How does a given shear stress affect a dislocation L shaped in the slip plane? Since the force per unit length is at all times normal to the dislocation line the edge dislocation moves normal to itself in the direction of b and the screw segment moves normal both to itself and to b . If one segment is not able to move, the one that glides may extend the motionless segment thus creating dislocation line, which requires energy. If it shortens the one that is motionless then the energy is released. This is illustrated in Lecture 7. How can the sense of direction of motion be determined ? It can be analyzed by vector algebra but it can be visualized by considering how the shear couple above and below the slip plane affects the displacement of the extra half-plane or the shear strain above and below the slip plane that arises from helicoids. When the shear stress is reversed the force on the dislocation and its glide are reversed. Such back and forth glide of dislocations is one element in fatigue failure. This is illustrated in Lecture 1.4, 4.4 and 5.5. How does a uniform shear stress on a plane affect a dislocation loop? The force per unit length on the dislocation in the slip plane, either pointing outwards all around or inwards all around. If the region inside is considered as slipped then an outward pressure (2 dimensional) causes it to expand until reaches the edges of the crystal, thus causing one slip step equal to b across external crystal. If the pressure is inward the loop contracts and annihilates as the opposite dislocations across from each other come into coincidence. This is illustrated in Lecture 16. Answers, page 27 What is the effect of stress on a dislocation that has a sessile segment that is not on the slip plane? Under a shear stress on the slip plane, the mobile segment will start to move except at the junction with the sessile segment. The mobile segment starts to rotate about the sessile segment. The pressure (2 dimensional) is always normal to it so it continues to rotate. If initially the line is normal to b , it is in edge orientation so that after 90o rotation the line is parallel to b and in screw orientation. After 180o rotation, the line is normal to b so it is in edge orientation; however the direction of the dislocation is now reversed relative to its original condition so the edge dislocation has a configuration of the opposite kind. After 270o rotating, it is in screw orientation but with opposite twist from that at 90o. After 360o it is once more edge in its original configuration. If the dislocation extends to the edge of the crystal then slip has been caused across the entire slip plane. The rotation can then repeat; such a mechanism is known as source. This is illustrated in Lecture 12. Does a dislocation require a critical level of stress to move? Yes, a stress is required to rearrange the bond lengths and directions that are distorted by the dislocation as it glides through a distance equal to b . This Peierls stress is strongly dependent on the crystal structure and the type and strength of atomic bonding. There is also a stress related to lengthening. Is the Peierls stress affected by temperature? Yes, it decreases as temperature rises primarily because the lattice crystals and atom positions are less well defined as vibration increases. Is the Peierls stress affected by impurities? Yes, it generally increases because of the impurity atoms interact with the dislocations because of difference in lattice size and in several other ways to be detailed later. The impurities may also form particles of a second phase through which the dislocations cannot pass since the slip planes and Burgers vectors are not compatible. Answers, page 28 What is the Cottrell interaction of a dislocation with atoms of different sizes? For an edge dislocation, big impurity atoms tend to take up positions in the tension zone (below extra half plane) and small atoms in the compression zone. This reduces energy associated with the impurity and with the dislocation. The effect becomes noticeable if many impurities, atoms have diffused to these preferential locations; these are known as impurity clouds or atmospheres. If the dislocation is moved away then its energy is varied and the cloud of impurities has a very high energy compared to a random distribution of impurity atoms. This is the mechanism of solute hardening and that whereby the impurities collect at freshly moved dislocations is called strain aging. Why is a stress required to lengthen the dislocation? If in the cores of dislocation motion it becomes larger then the energy per unit length must be supplied; thus the expansion of a loop requires a minimal stress due to this as well as overcoming the Periels stress. When the stress is removed the dislocations could move back to become shorter but may be prevented by the Peirels stress. Answers, page 29 MULTIPLICATION OF DISLOCATION How does plastic strain affect the flow stress? The flow stress σ increases with strain ε as a result of strain hardening; the rate is dσ/dε = θ. The glide of dislocations evidently becomes more difficult. What is the most commonly observed behavior of dislocations during strain hardening? Strain hardening is always associated with increase in density of the dislocations i.e. the quantity per unit volume. These are other interactions to be described later. How is the density of dislocations reported and measured? The density is reported as the total length of dislocations per unit volume or the number of dislocations threading through a unit area of surface. The first is determined by measuring the total length in a thin foil observed in TEM; it is necessary to determine the thickness. The second is usually measured by counting the number of etch pits per unit area. The units of both measures are the same, ( , m-2). How does the dislocation density increase during straining? A small part of the increase is due to the rise in length of the dislocation as loops expand and do not leave the crystal. The largest increase arises from the generation of new dislocation loops from the ingrown dislocations, these are known as sources. The most famous was invented by Frank and Read. What is the nature of a Frank-Read source? The Frank-Read source consists of a segment (horizontal at left A, right B) in a slip plane (the paper) while the segments at both ends (beyond A and B) are not in a slip plane and cannot move (sessile). Under a shear stress on the slip plane, the mobile segment moves upwards remaining an arc of circle between A and B but of decreasing radius until the diameter is on the original segment position (AB). After that the arc length and the diameter increases while the ends remain attached to the sessile pinning segments. With continued application of stress the semi-loop expands in diameter while the sections near the pins swing around further becoming lobes or spirals. The pinned ends of these two spirals rotate enough to approach the line of the original segment; meanwhile, the two lengths of the lobes or spirals that are normal to the line of the original segment approach each other. When they meet they annihilate each other creating both a free loop and a segment, which is close to the line of the original segment. This short-pinned segment can repeat the process to create another free loop. illustrated in Lecture 13. This is Answers,,page 30 How do the two lobes or spirals of the Frank-Read source pinch off? To carry out the analysis, the original dislocation segment is arbitrarily assigned a direction from left to right (A to B). It is further assumed that it is a screw dislocation with b from A to B. The portions of the lobes or spinals those are parallel to each other and approaching need to be analyzed as follows. The vertical length below A has a direction from A downwards with a Burgers vector left to right. The vertical length below B has a direction upwards towards B with b left to right. To consider the two segments with the same direction (both downwards, then the direction of the part below B is reversed along with its b . Now the two b are opposite indicating a potential for annihilation. It can also be seen that the vertical length below A is an edge dislocation with extra half a plane below the slip plane and that below B is also edge but with the extra half plane above the slip plane; Once pinching off has occurred the segment from A to B is continuos with the correct sense from A to B; similarly the free loop is continuous with the same sense of direction throughout. This is illustrated in Lecture 8. What is the effect on the dislocation array of the Frank-Read source? The free loops from the Frank Read source continue to expand under the applied shear stress and form a series of concentric circles centered on the source. If the stress application is continued at the same intensity, the number of loops increases and each marches towards the surface of the crystal. The density of dislocations is greatly increased and much slip developed near the origin of the source due to the passage of all the loops. Are there types of sources different from the Frank-Read source? Yes, there is a single ended source that has already been described. A dislocation rotates around a single sessile segment. The rotating dislocation does not remain straight but becomes a spiral; one turn of the spiral is equivalent to a single free loop. Is the Frank-Read source more significant then the single ended? Yes statistically, since for an irregular ingrown dislocation, it is more likely that it is pinned at both ends than that it has a long segment on the slip plane, reaching the surface. The single ended source is essentially half of a Frank-Read source. Answers,page 31 What happens if there are two Frank-Read sources on the same slip plane? Both sources will operate and the loops of each expand until they meet. The meeting parallel segments will pinch off since they will have opposite b when the dislocation line directions are assigned the same. The result will be bigger loops that embrace both sources. Do all Frank-Read sources start to operate at the same stress? No, the stress to operate a source is greater for shorter segments between sessile pins. However, many start to operate over a narrow stress range. Below that range the segments bow out but return to their position when the stress is removed. What happens when the loops reach the free surface of a single crystal? When one loop exits the crystal the opposite edge segments produce steps on the opposite forces that displace the upper half of the crystal relative to lower half. This is equivalent to a single edge dislocation moving entirely across the crystal. When the opposite screw segments exit they produce the strain that accommodate the steps due to edges yet are not visible. Each succeeding dislocation loop produces the same effect. This is illustrated in Lecture 14 and 16. Answers, page 32 YEILDING AND STRAIN HARDENING How is the operation of Frank-Read sources related to macroscopic behavior? The operation of multiple sources in many slip bonds produces sufficient strain to result in yielding. Before this at stresses just below there is evidently considerable movement of dislocations known as micro slip, some of which is reversed on removal of the stress. How is the operation of Frank-Read sources related to slip lines optically visible? A slip Lecture is composed of slip steps on a group of closely spaced planes. A single step could be the result of the operation of a source on one slip plane that releases hundreds of dislocations. This action seems to trigger sources on planes hundreds of atom layers apart; the packet of sources on many planes creates the slip step. How much strain is produced by the glide of the dislocations? The strain depends on the total length of dislocations moving per unit volume ( m mobile) and the average distance they glide, d gl . Thus b m d gl gives theoretical strain. The mobile dislocation density excludes the sessile segments not on the slip planes and also segments strongly pinned by particles or other obstacles; it is rather difficult to determine. If varies with strain because the total density keeps increasing although many of these new segments block each other, Likewise d gl must be determined from slip traces and also varies with strain. Careful studies have confirmed the validity of the equation and hence of dislocation theory. What happens in a polycrystal when the source is in a grain enclosed on all sides by other grains? In general, the loops cannot pass across the grain boundary into neighboring grains with completely different alignment of the slip systems. The loops can be thought of as piling up at the grain boundary where they repel each other and create a stress field that extends into the neighboring grains. What is the effect of a pile up of loop at grain boundary? The first loop stops because it cannot enter into the crystal with a different orientation. The second loop stops some distance from the first because it is repelled by the stress field of the first. The third loop to arrive stops at spacing from the second that is greater than that between second and first because it feels the repulsion of the combined stress feels. This proceeds with additional loops, the spacing becoming larger. This process stops when the issued loops exert a back stress on the source that equals the applied stress. This is strain hardening due to the pile up theory; there are still other models. Answers, page 33 DISLOCATIONS AND THERMAL VIBRATIONS Do the vibration of the atoms aid dislocation motion? Yes, increased vibrations of the atoms assist dislocations to overcome the Peierls force. Since the thermal energy is not uniform but varies regionally with time (phonons), dislocation motion may be assisted over only short segments this is known as thermal activation. In contrast to this, dislocation motion under stress affects the local vibrations generating phonons. What happens to the work done as the dislocation moves under stress? The work is mainly dissipated as heat. The motion of the distortion ripple alters the vibration of the atoms; it can be said to emit phonons. Some of the work is stored in the increased length of dislocations. Answers, page 34 CROSS-SLIP OF SCREW DISLOCATIONS Can a screw dislocation change slip planes? Yes, since a screw dislocation is parallel to its b , there could be many potential slip planes depending on the crystal structure; in simple cubic these are 2 cube faces normal to each other. A dislocation may be spread out as Lecture on one slip plane, so it would have to contract into a perfect line to change to a second slip plane. This is known a cross slip. The dislocation does this in response to a shear stress on the second plane. Part of the energy for the contraction comes from thermal vibrations known as thermal activation. This is illustrated in Lecture 9. Does cross slip become more frequent at higher temperature? Yes, the increased thermal activation makes cross-slip more frequent. Does the whole segment need to cross slip at once? No, once a short part of the segment is established on the new plane it may spread progressively along the line as thermal activation assists the changeover in association with the stress. What is evidence for such cross-slip? The cross slip can be observed in TEM. It is also observed on the surface of a deformed crystal as undulating slip planes known as wavy glide. It is seen in Al at near room temperature and in other metals under creep conditions. The wavy glide would indicate that there are shear stresses acting simultaneously on two different slip planes. What is the result of screw segment of a loop undergoing repeated cross slips? If one imagines only the screw segment gliding and cross slipping then it creates at each end segments of edge dislocation. The loop then lies on a corrugated or wavy surface. The associated edge segments are undergoing pencil glide. Answers, page 35 CLIMB OF EDGE DISLOCATIONS How can edge dislocations move in directions not in the slip plane? The edge can move normal to the slip plane by the removal of atoms from the extra half plane by arrival of vacancies (upwards for extra half plane above slip plane). The addition of an atom is related to the creation of a vacancy in the adjacent lattice (downward climb). A climb could be combined with glide to produce motion at various angles. This is illustrated in Lecture 10. How does the climb process proceed? When a vacancy arrives at the extra half-plane, it moves the dislocation upwards to the next slip plane and leaves a step or kink on each side. This double kink can migrate or diffuse along the dislocation line until it meets another such step upwards to the next slip plane. Addition of more vacancies gradually causes a greater length of dislocation to transfer upwards. Vacancies usually arrive in large numbers when there is an excess concentration. Addition of atoms to the extra half-plane results in downward kink that behaves similarly to above; this occurs when there is deficiency in vacancy concentration. This is illustrated in Lecture 10. What are the relative rates of climb and glide? Climb tends to be very slow since a vacancy must arrive or leave for each atomic plane intersected by the dislocation just to climb from one slip plane to the next. The temperature dependence is the same as that of self-diffusion being very limited at 20oC in Al (0.32 Tm, melting temperature, K) but becoming very rapid at 0.9 Tm (570oC). In comparison the possible rates of glide are little affected by temperature. How is this behavior described in terms of vacancy dynamics? The dislocation is said to be a vacancy source when the extra half plane extends (downward climb) and a vacancy sink when the extra half plane diminishes in extent (upward climb). The dislocations serve as sources as temperature and vacancy concentration rise and as sinks as temperature declines along with vacancy concentration. Answers, page 36 Can stress play a role in edge dislocation climb? Yes, a stress normal to the extra half-plane can influence the direction of climb. Compression is relaxed by withdrawal of the extra half plane (upward climb, sink) whereas tension is relaxed by the extension of the extra-half lane (down ward climb, source). This effect contributes to creep and also to recovery. How does climb contribute to the recovery of a pile-up? In a pile-up of edge dislocations near a grain boundary (or other obstacle) there is a very high compressive stress on the side of the slip plane with the extra half-planes (say above the slip plane). If a dislocation segment climbs upward as a result of a random thermal fluctuation, the compressive stress reinforces that motion causing upward climb. In contrast if a segment fluctuates downwards it comes under a tensile stress that encourages additional downward climb. In addition, vacancies are subjected to a gradient causing them to diffuse from these climbing downwards to these climbing upwards. Statistically half the dislocations in the pile-up may climb upwards are half move downwards causing the recovery or decomposition of the pile up. What is the result of the recovery of a pile up? The piled-up dislocations of like sign cause upwardly convex distortion of the slip plane, if the extra half planes are above it. The climb alone tends to distribute the dislocations randomly above and below the slip plane due to their mutual compression and tension fields. However, their mutual shear fields tend to cause edge dislocations fairly near each other on different planes to glide into positions one above the other. The net result is the conversion of the pile up into tilt walls normal to the original slip plane. What is a tilt wall and what happens as a result of climb? A tilt wall consists of similar edge dislocations one above the other, held there by their mutual shear components. It is called a tilt wall because the extra half planes as a group, act as a wedge in the plane of the wall tilting the two sides. The mutual compression-tension field of the edge dislocations causes them to climb away from each other diminishing the angle of the tilt and becoming equally spaced in the process. Answers, page 37 How does climb of opposite dislocations lead to annihilation? Parallel edge dislocations with opposite b on different slip planes will locate as a result of their stress fields on a plane at 45o to their parallel slip planes. Their stress fields exert a strong mutual attraction; they move towards each other on the 45o plane by a combination of climb and slip. One dislocation serves as a sink and the other as a source leading to a flow of vacancies between them. What happens when a dislocation loop is subjected to climb conditions? The edge dislocations are subject to climb normal to the slip plane. The screw segments will remain in the original slip plane unless they are subjected to shear stresses on cross slip planes whereby they might follow the edges. Segments connecting the edges to the screws are edge type and are sessile relative to the original slip plane or any parallel to it. The edges on new planes and the screw components on the original slip plane could act as sources to create slip loops (Lectures 13, 14). This process can develop loops on corrugated surfaces and wavy slip.