lab3_compound_pendulum

advertisement

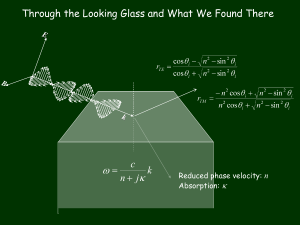

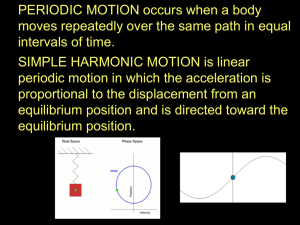

Department of Mechanical Engineering ME 260W - Measurement Techniques Spring 2005 Experiment #3: Motion Analysis of a Compound Pendulum 1. OBJECTIVES The objectives of the experiment are: i) ii) iii) To introduce a sensing device, Rotary Potentiometer. To introduce the student to signal conditioning as applied to critical timing measurements and motion analysis of a compound pendulum. To apply basic statistical procedures for the purpose of data reduction, model fitting and correlation 2. EQUIPMENT Rotary Potentiometer, RP100 Series Compound Pendulum AC/DC Variable Elenco Power supply, Model XP800 Tektronix Digital Storage Oscilloscope; Model TDS 210 Computer station with data acquisition A/D board 3. DESCRIPTIONS Theory Considering the motion of a compound pendulum, which is illustrated in Fig. 1, the potential energy V and kinetic energy T at any arbitrary state of position and velocity are given as: V m g L1 - cos (1) I 0 θ 2 T( θ) 2 (2) dθ where is the angle measured from the vertical equilibrium position, and θ is the angular dt velocity. The total energy of the pendulum at any instant in time is thus: I 2 E , V T m g L 1 cos 0 2 1 (3) O L CG d A mg Fig. 1 A Compound Pendulum. If the system is conservative (no energy dissipation), the total energy is constant with a value dictated by the initial values of and θ . In this case, the differential equation of motion of the pendulum can be found by differentiating the energy with respect to time; Thus, differentiating equation (3) results in; I 0 m g L sin 0 (5) which can be simplified to: mgL sin 0 (6) I0 Equation (6) is the governing differential equation of motion for a pendulum. The second term is non-linear, which means that equation (6) does not have a simple, straightforward solution. We treat below, small and large angle () cases separately. Small Angle Oscillations: Linearized Equation of Motion If one considers small angles (from the equilibrium position), the equation can be linearized by the approximation (7) sinθ θ mgL Yielding (8) 0 I0 Equation (8) describes a simple harmonic oscillator; for the case where the initial velocity is zero, the solution is given by: t cosn t (9) where is the intial angle of the pendulum, and n mgL is the frequency of oscillation. The I0 period of oscillation, or time needed for the pendulum to make a complete cycle, is related to the natural frequency by: n 2 (10) n It should be emphasized that this is the period for small oscillations, since the solution was obtained by the assumption (Eq. 7), which is only valid for small angles. 2 Large Angle Oscillations and Non-Linear Effects Consider now the case where the restriction of small angles is removed. The governing equation is given by equation (6). Rather than solving this explicitly for the angle, , as a function of time, we wish merely to derive an expression for the period of the oscillation as a function of initial angle. This expression will replace equation (10). Again, we start by noting that the total energy of the system is constant. The value of this energy is dictated by the initial angle of the pendulum; for free vibration, the initial angle is the maximum angle reached during oscillation. The energy of the pendulum system at any given instant is; E , 0 m g L 1 cos (11) Equating this to the right-hand side of equation (3) and re-arranging, we obtain: m g L cos - cos I 0 d 2 dt 2 (12) We can put this equation in a differential form in terms of and t: 2mgL I0 where n mgL I0 cos cos d dt 22n cos cos or d dt (13) (rad/sec) is the angular frequency as before. This nonlinear ODE is in the form of θ f θ and it can be solved numerically using many ODE solvers such as Runge-Kutta, Adams Bashfort etc. (Commercial codes, such as MATLAB, SIMULINK or MAPLE can help you substantially in this). Find the period for different initial conditions (’s) and show that the curve in Fig. 2 holds. Notice that for linear case (i.e. small angle oscillation) n 1 and this feature disappears as the swing angle, , increases. Friction The exact nature of the friction present in the experiment is indeterminate. Two types of friction that might be in effect are viscous friction and Coulomb (or dry) friction. The effect of these two types will be established by considering linear mass-spring systems with damping. Viscous friction Viscous friction is characterized by a damping force that is proportional to angular velocity. It is a convenient assumption, since the governing differential equation of motion remains linear. Referring to Fig. 3a, the differential equation for the translating mass is given as: mx cx kx 0 (14) where the first term is the inertial term, the second term is the viscous damping term, and the last term is the force from the displaced spring. It is convenient to normalize in the following form: x 2 n x n2 x 0 (15) 3 k c is the natural frequency of the system, and is referred to as the m 2 km damping ratio. If the system is given an initial displacement x0 and released, the resulting motion will take the form (see your vibration textbook): where n x0 x(t) 1 2 e n t cos( d t φ) (16) where d n 1 2 is the damped natural frequency and the phase angle is given by: 1 2 tan 1 (17) The response described by equation (16) has the basic form of an oscillating signal with decaying amplitude. The amplitude shows an exponential decay. The response of a viscously damped mass-spring system is illustrated in Fig. 3b. Regardless of the value n, the relative size of the (n+1)th oscillation with respect to nth, xn+1/xn is given by (derive this equation from 16): x 2π δ ln n 1 xn 1 2 (18) For small amounts of damping, is small and the denominator in equation (18) is approximately equal to one. The quantity is commonly referred to as the logarithmic decrement. It can be numerically calculated. For small damping, damping ratio parameter, , can be approximately evaluated directly from the relationship: (19) 2 Period multiplier, /n 1.08 1.06 1.04 1.02 1.00 0 10 20 30 40 50 60 Swing angle , deg Fig. 2 Correlation between period multiplier and swing angle of the compound pendulum. 4 x c cx kx m m k Fig. 3a A viscously damped mass-spring system and its free-body diagram. Relative displacement. 0.8 0.4 0 -0.4 -0.8 0 5 10 15 20 Oscillation number Fig. 3b The response of the viscously damped mass-spring system. Notice that d is measurable (from motion data). Once the ratio, , is found, using d n 1 2 relationship n can be calculated. Coulomb friction The nature of Coulomb friction is that the friction force is proportional to the normal force pressing the mass against the friction source (e.g. the plane that the block slides on), and is in the direction opposite to the velocity. This basic energy dissipation mechanism is shown in Fig. 4a; the resulting equation of motion is given by: mx μN sign x kx 0 (20) The solution of this equation is obtained in a piecewise linear manner (see your vibration textbook). That is, there is a sequence of equations that describe the motion. If one examines the transient plot of displacement created from this sequence of equations, the decay in amplitude of 5 displacement is linear. (This is in contrast to the exponential decay predicted by Coulomb friction.) The amplitude decrease per cycle is 4μN/k (Fig. 4b). The associated decay ratio is: xn x0 1 4nN or x n x n 1 kx 0 4N (21) k In summary, one can determine which of these two types of friction is present by examining the representative plots of ln(xn/x0) vs. n (where n is the cycle number) and xn/x0 vs. n. If viscous damping is dominant, the correlation will be higher using the first relation, while the second relation better supports the presence of Coulomb damping. N N x x kx m m μsign x k N Fig. 4a A mass-spring system with Coulomb damping and its free-body diagram. Relative displacement. 0.8 0.4 0 -0.4 -0.8 0 5 10 15 20 Oscillation number Fig. 4b The response of the mass-spring system with Coulomb damping. 6 4. EXPERIMENT 1. Test Equipment Study the behavioral characteristics the rotary potentiometer. Establish the nature of the respective signals as related to the motion of the pendulum. Describe them in your report. The experiment set-up is shown in Fig. 5. Computer SCXI Chassis Pendulum Power Supply Oscilloscope Fig. 5 Experimental set-up. 2. Small Amplitude Test For small amplitude oscillations, the period is approximately constant regardless of initial displaced angle. Set up the mechanical reference equipment to measure the swing angle and the oscillation period. Obtain a sufficient number of measurements for angular motion to have a reliable database. Repeat your tests in order to gain confidence and reliability in the experiment. These recordings will be in the form of vs. t. 3. Oscillation Period as a Function of Swing Angle (To avoid injury, make sure all hands and fingers are sufficiently away from the pendulum before it is released!!!) Establish the maximum angle of swing that can be practically accommodated by the test equipment. Divide this maximum angle into approximately six to eight equal subdivisions, and carry out measurements of oscillation period as a function of swing angle. Repeat the test at each reference angle and obtain the statistical properties of your data, again in the form of vs. t. 4. Friction Quality Test In order to obtain an assessment of the type of friction present in the experiment , obtain a record of swing angle vs. oscillation number. Start with a sufficiently large initial swing angle, but not the maximum that was used in part 2. Select a progression that you can reasonably handle and measure the associated periods. Carry out this process until the swing angle has decreased to one half of its original value. Run the simulation exercises using ODE solvers (mentioned earlier) for the case when both viscous and coulomb frictions exist. Using this data try a least square method to find the best fitting combination of viscous and coulomb friction components. Determine the statistical properties of your data and quantify the degree of confidence you have in your results. 5. A known mass is used to determine the moment of inertia of the compound pendulum (I0) and its center of gravity (L). We place an additional mass at a known location, and measure the periods of swings (in linear zone). From the existing two sets of data (the periods of swings: one with and the other without the added mass), the two quantities of interest (I0 and L) are evaluated. 7 Find the 90% confidence intervals for both inertia and the center of gravity. 6. Acquiring Test Data Exercise 1 Raw Data Acquisition In this exercise, pendulum LabVIEW VI (Fig. 6) is used to collect voltage raw data. These data will be used later in another Vi to find the period of pendulum and angular displacement. After setting the parameters on the front panel of the VI, the pendulum is released from rest at a given initial angular displacement and the VI is run. After sampling the signal from the encoder for a predetermined length of time, the sampled signal is displayed and the period of the pendulum can be found. Taking Measurements: 1. Establish the maximum angle of swing that can be practically accommodated by the test equipment. Divide this maximum angle into subdivisions, and carry out measurements of oscillation period as a function of swing angle. 2. Make sure your workstation is setup in the following manner; Open “pendulum VI” (c:\me260w\lab3_pendulum lab\ pendulum.vi) 3. Make sure the SCXI chassis is turned on; 4. Insert a 3.5” diskette into the disk drive; 5. Set the following parameters on the VI: Device: 1 Channels: 0 Scan rate: as desired (e.g. 100) Buffer size: (should be 5 x scan rate) Scans to read: same as scan rate or more Input limits 0 high limit: 0, low limit: 0 Interchannel delay: -1.0E+0 Initial angular position: 0 Initial direction: 1 6. Input a filename such as a:\data1.txt\ in the output file block of the VI. Two file names will be saved; voltagedata1.txt and displacementdata1.txt; 7. Release the pendulum from a selected position when the front panel appears; 8. Repeat the test at each reference angle; 9. Observe the angular displacement and the period of the pendulum. 8 device 1 channels 0 0 scan rate 10.0 0.0 (1000 scans/s ec) 100.00 -10.0 buffer size (4000 scans) -20.0 20000 -30.0 scans to read at a ti me (1000) -40.0 4000 hardware settings -50.0 input li mits -60.0 0 high li mit 0.00 -70.0 low limi t -80.0 0.00 7.9 8.0 8.1 8.2 8.3 8.4 interc hannel del ay in secs ( - 1: hw default) -1.00E+ 0 Fig. 6 Pendulum VI. 9 8.5 8.6 8.7 8.8 8.9 9.0