EXPERIMENTAL DETAILS

advertisement

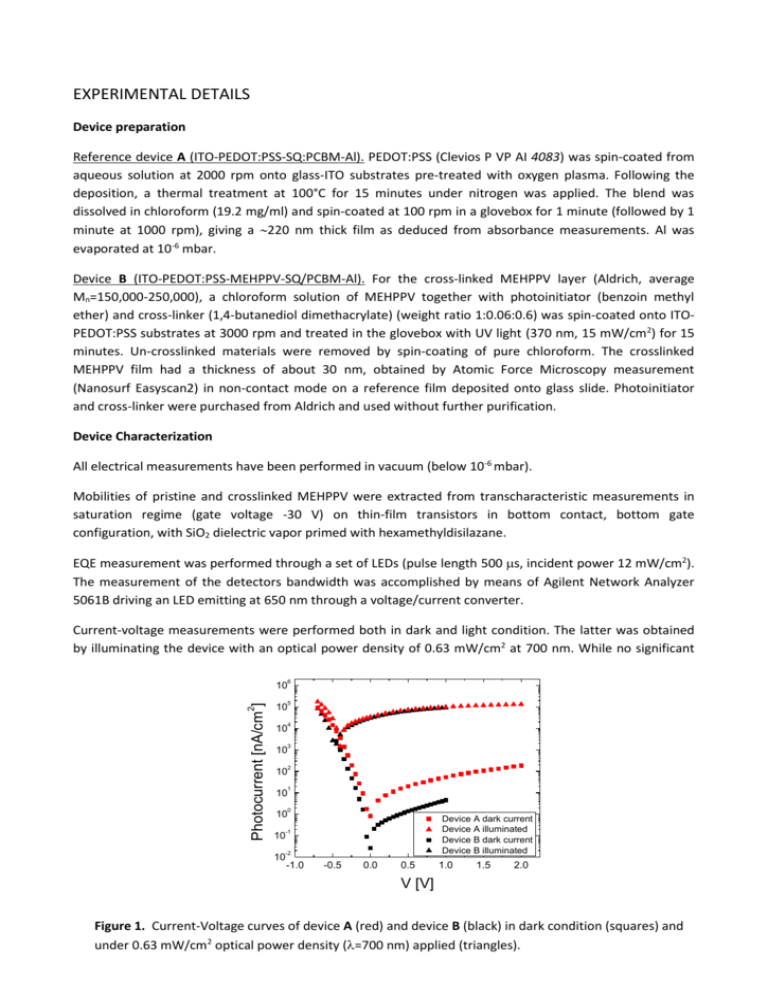

EXPERIMENTAL DETAILS Device preparation Reference device A (ITO-PEDOT:PSS-SQ:PCBM-Al). PEDOT:PSS (Clevios P VP AI 4083) was spin-coated from aqueous solution at 2000 rpm onto glass-ITO substrates pre-treated with oxygen plasma. Following the deposition, a thermal treatment at 100°C for 15 minutes under nitrogen was applied. The blend was dissolved in chloroform (19.2 mg/ml) and spin-coated at 100 rpm in a glovebox for 1 minute (followed by 1 minute at 1000 rpm), giving a 220 nm thick film as deduced from absorbance measurements. Al was evaporated at 10-6 mbar. Device B (ITO-PEDOT:PSS-MEHPPV-SQ/PCBM-Al). For the cross-linked MEHPPV layer (Aldrich, average Mn=150,000-250,000), a chloroform solution of MEHPPV together with photoinitiator (benzoin methyl ether) and cross-linker (1,4-butanediol dimethacrylate) (weight ratio 1:0.06:0.6) was spin-coated onto ITOPEDOT:PSS substrates at 3000 rpm and treated in the glovebox with UV light (370 nm, 15 mW/cm2) for 15 minutes. Un-crosslinked materials were removed by spin-coating of pure chloroform. The crosslinked MEHPPV film had a thickness of about 30 nm, obtained by Atomic Force Microscopy measurement (Nanosurf Easyscan2) in non-contact mode on a reference film deposited onto glass slide. Photoinitiator and cross-linker were purchased from Aldrich and used without further purification. Device Characterization All electrical measurements have been performed in vacuum (below 10-6 mbar). Mobilities of pristine and crosslinked MEHPPV were extracted from transcharacteristic measurements in saturation regime (gate voltage -30 V) on thin-film transistors in bottom contact, bottom gate configuration, with SiO2 dielectric vapor primed with hexamethyldisilazane. EQE measurement was performed through a set of LEDs (pulse length 500 s, incident power 12 mW/cm2). The measurement of the detectors bandwidth was accomplished by means of Agilent Network Analyzer 5061B driving an LED emitting at 650 nm through a voltage/current converter. Current-voltage measurements were performed both in dark and light condition. The latter was obtained by illuminating the device with an optical power density of 0.63 mW/cm2 at 700 nm. While no significant 6 2 Photocurrent [nA/cm ] 10 5 10 4 10 3 10 2 10 1 10 0 10 Device A dark current Device A illuminated Device B dark current Device B illuminated -1 10 -2 10 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 V [V] Figure 1. Current-Voltage curves of device A (red) and device B (black) in dark condition (squares) and under 0.63 mW/cm2 optical power density (=700 nm) applied (triangles). differences can be observed (Figure 1) between device A and device B with direct bias applied, a remarkable discrepancy arises between the dark currents in reverse bias condition, stressing the key role played by the MEHPPV-based blocking layer in suppressing electrons injection from the ITO/PEDOT:PSS contact into the active material. To investigate the working regime of the organic photodetectors, measurements of photocurrent dependence on both the incident optical power (P) and the voltage bias were accomplished on devices with ITO-PEDOT:PSS-SQ:PCBM-Al structure. Optical power output was varied by tuning the LEDs driving current and was calibrated by means of a silicon photodetector with known responsivity. Photocurrent response at different bias voltages was also recorded for detectors shined with continuous wave optical signal (P=1.6 mW/cm2, =700 nm). From Figure 2(a) it can be observed that the photocurrent grows linearly with the incident light intensity for values below 4 W/cm2, showing instead a P0.84 dependence at higher power densities. In Figure 2(b), the dependence of the photocurrent on the effective bias voltage, calculated as the externally applied voltage plus the built-in voltage, is shown: it can be noticed that the photocurrent grows with the square root of voltage. Both these observations suggest that the photodetector operates in a space charge limited current regime, accordingly to the demonstrations of Mihailetchi et al. (ref. 20) and Koster et al. (ref. 21). 20 Vapplied+Vbi=1.45 V P = 1.6mW/cm 2 0 Iph [A] Iph [A] 1x10 -1 1x10 10 -2 1x10 (b) (a) -3 1x10 0.1 1 10 100 2 Power density [W/cm ] 0.1 1 Vapplied + Vbi [V] Figure 2. (a) Detector’s photocurrent as a function of the incident light intensity (Vbias=1 V, =700 nm). The red line represents a linear increase of the current- (b) detector’s photocurrent as a function of bias voltage (the built-in voltage is 0.45 V). The incident optical power is 1.6 mW/cm2 (=700 nm). The red line represents the increase of the photocurrent with V0.55 on a logarithmic scale.