18th European Symposium on Computer Aided Process Engineering – ESCAPE 18

Bertrand Braunschweig and Xavier Joulia (Editors)

© 2008 Elsevier B.V./Ltd. All rights reserved.

Optimization of caustic treatment processes of

zeolite sorbents

Alexander A. Ermakov, Dmitry S. Dvoretsky, Stanislav I. Dvoretsky

Department of Chemical Engineering, Tambov State Technical University,

ul. Sovetskaya, 106, 392000 Tambov, Russia

Abstract

Introduction of the caustic treatment stage in traditional technologies of the granulated

zeolite sorbents (GZS) production allows to obtain sorbents with improved properties:

higher mechanical strength, statical and dynamical capacity. Mathematical model has

been developed to describe the aggregate of the physical and chemical processes

which determine changes in the sorbents’ properties. Optimization problem has been

solved for industrial prototype of zeolite sorbent 4A, which is broadly used for

refinement and drying of cooling agents.

Keywords: zeolite sorbents, caustic treatment, process modelling and optimization.

1. Introduction

Traditionally there exist two ways of obtaining GZS. The first one is the synthesis of

zeolite crystals and their consequent granulating with the coupling agent – usually clay

mineral. This production method has three main advantages: technological simplicity,

possibility to produce at large capacity and relatively low production costs. However, in

this case adsorption properties of GZS decrease in comparison with initial zeolite and

mechanical strength is not very high.

Second method of GZS production involves preliminary clay formation and its

crystallization into zeolite during hydrothermal synthesis in caustic solution.

Subsequently treated GZS are virtually pure zeolite without coupling agents and with

high mechanical strength and adsorption capacity. But this technology is more

complicated due to unstable physical and chemical properties of raw alumosilicate

material. Besides, production costs are significantly higher and the production cycle

itself is more time-consuming as multistage hydrothermal synthesis is involved.

The conducted research [Ermakov A., 2003] allows recommending the third approach to

GZS production. According to this method, after molding zeolite crystals with coupling

agent and calcinating the obtained granules, one more technological operation is carried

out, particularly, their hydrothermal treatment with caustic solutions. This increases

mechanical strength and adsorption capacity of granules and decreases diffusion

resistance, whereas production costs are kept relatively low.

During caustic treatment a number of physical and chemical phenomena take place on

the surface and within zeolite granules, and this complicates the question of its

industrial implementation. Thus establishing multifunctional dependency between GZS

properties and caustic treatment conditions is extremely topical. Both experimental

research into mechanisms and kinetics of physical and chemical processes and

mathematical description of experiments with regard to uncertainty of physical and

chemical properties of natural alumosilicate coupling agents, are needed. This paper

concentrates on the latter task.

2

A. Ermakov et al.

2. Mechanisms of caustic treatment process

Modification of physical and chemical properties of GZS during caustic treatment is

caused by the following processes:

- source components of GZS, coupling agents (claying mineral) and adsorbent

(synthetic zeolite) in the interaction with caustic solution are partially dissolved with the

emergence of elementary silicate and aluminate ions;

- as a result of polycondensation between hydrated silicate and aluminate ions,

alumosilicate ions and colloid structures of amorphous alumosilicate are formed;

- due to the continuous dissolution of the alumosilicate structures, crystallization centers

are formed and zeolite crystals grow in situ.

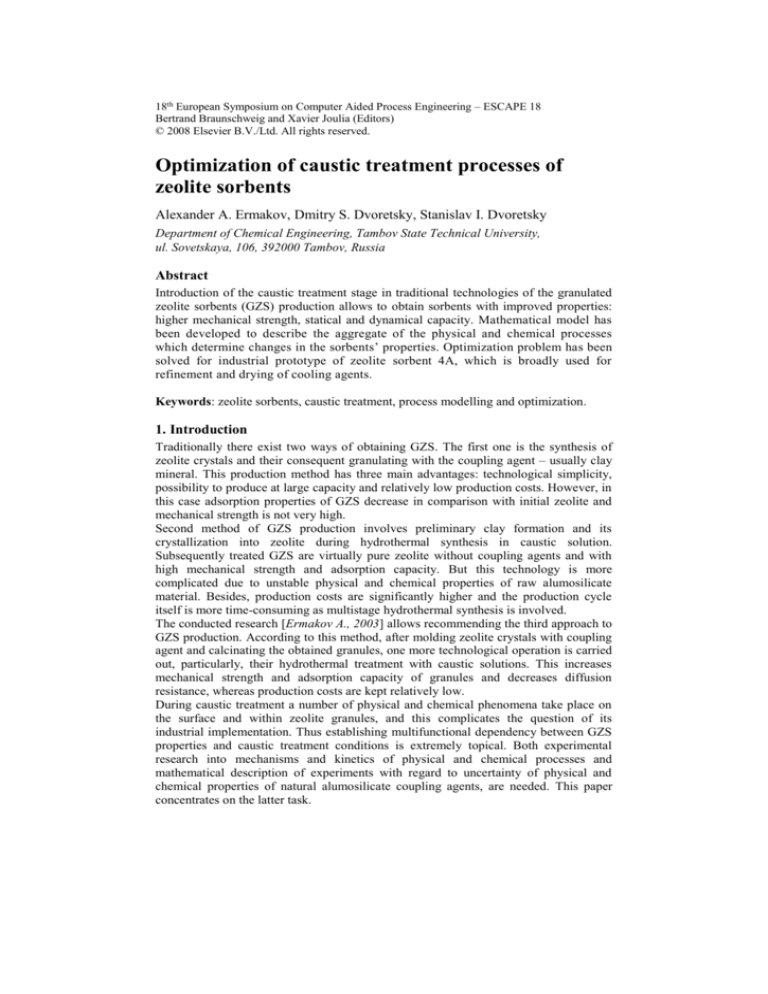

Generalized diagram of these processes is presented in Figure 1.

At the initial stage of caustic treatment the caustic solution diffuses into zeolite sorbent

granules and clay coupling agent partially dissolves giving birth to elementary

aluminate and silicate ions. Original zeolite crystallite has greater chemical resistance to

dissolution in caustic; that is why during zeolite crystallite and caustic interaction only

small part of silicate and aluminate ions is dissolved and there are no significant phase

changes in zeolite structure. With accumulation of elementary aluminate and silicate

ions in caustic solution a new process takes place: synthesis of alumosilicate gel, which

properties drastically contrast the initial clay coupling agent. In general terms, this gel is

formed during polycondensation of elementary and compound silicate and aluminate

ions. The forming gel represents metastable phase and repeatedly dissolves in caustic

solution to form compound alumosilicate ions, the nuclei of crystallization and zeolite

phase.

Aggregate of the described physical and chemical processes causes changes in

adsorption and mechanical properties of GZS. Re-crystallization of clay coupling agent

into zeolite phase gives 25% increase of adsorption capacity. During GZS caustic

treatment, adsorbate diffusion also increases up to 70% due to changes of secondary

porous structure and formation of pores. In quantitative terms, increase in secondary

pores volume fluctuates widely (3 to 150%) and largely depends on the concentration of

caustic agent and duration of treatment. Increment of GZS mechanical strength up to

200% is related to the formation of amorphous alumosilicate and claying properties of

particles of the emerging gel structure.

3. Mathematical model of caustic treatment process

Based on the mechanisms of physical and chemical processes described above,

mathematical model of GZS caustic treatment includes the system of partial differential

equations (1)-(5) of controlled diffusion reactions (CDR) and balance equations of

liquid and solid phases.

Mathematical description of GZS caustic treatment process has been formulated taking

into account the following assumptions: 1) the process of single particle caustic

treatment of GZS and process in the unit reactor behave the same; 2) the process runs in

isothermal conditions; 3) the particle has a canonic shape (cylinder, sphere); 4) there is

no gradient of concentrations in the liquid phase; 5) the particle is isotropic from the

diffusion standpoint.

Optimization of caustic treatment processes of zeolite’s sorbents

Clay

Caustic solution

Me , OH

Me 2 O Al 2 O3 xSiO2

3

Zeolite (4A)

Na 2 O Al 2 O 3 2SiO 2

n

Dissolution

HO y Si (O Me ) 4 y

Dissolution

HO y Si (O Me ) 4 y

Al (OH ) 4 Me

Al (OH ) 4 Me

Polyfunctional condensation of hydrated ions

Al OH HO Si Al O Si H 2 O

Ion exchange

Na Me

Dissolution

Hydrolysis of endgroups

OY Si (O Me ) 4 y H 2 O O y Si (O Me ) 4 ( y 1) OH MeOH

Alumosilicate gel

Solid phase of gel

Liquid phase of gel

Al Me OSi

1

Me , OH , Al (OH ) 4 , HO y Si ( O ) 4 y , Al O Si

Si

3.3

Al

0,15

Si

25

Al

Polyfunctional condensation of alumosilicate ions

of fixed composition and structure, formation and

crystal growth of zeolite

Me 2 O Al 2 O 3 zSiO 2

Figure 1. Diagram of physical and chemical processes during caustic treatment

Thus, caustic treatment of GZS can be mathematically described as:

- a system of partial differential equations of CDR

Ci ( r , )

2 Ci ( r , )

Dei ( t )

f ( Ci ) for i 1..10

r 2

(1)

with initial

Ci ( r ,0 ) СiН for i 1..10

(2)

and limits at

Dei ( t )

Ci ( 0 , )

0 for i 1..10

r

(3)

for r Rч , 0

Dei ( t )

Ci ( Rч , )

ч Ci ( Rч , ) Cip ( t ) for i 1..10

r

(4)

and balance equations of liquid and solid phases

М р (Сiрj 1 Ciрj ) M Т (Сi j 1 Ci j ) i m f Ci

(5)

4

A. Ermakov et al.

where parameter i possesses the value 1 - Si - hydrated silicate ion; 2 - Al - hydrated

aluminate ion; 3 - AlSix1 - compound hydrated alumosilicate ion; 4 - MeOH - caustic

Clay

agent; 5 - SiO 2

- SiO2 content in clay; 6 - Al2O3Clay - Al 2 O3 content in clay; 7 -

SiO2Zeolite - SiO2 content in zeolite; 8 - Al2O3Zeolite - Al 2O3 content in zeolite; 9 - AlSix -

amorphous alumosilicate; 10 - K or Li - cation, f ( Ci ) - variation of

concentration of component i.

The equations of non-linear boundary problem of controlled diffusion reactions of GZS

caustic treatment process have been calculated with the help of finite-difference method

with implicit difference scheme and four-point model. Calculation results that illustrate

variation of the GZS composition and caustic solution are presented in Figures 2A-2C.

8

75

Clay in GZS

Zeolite in GZS

A

70

Silica-alumina gel in GZS

Alluminate in solution

Silicate in solution

B

7

65

Concentration, % mass

Concentration, % mass

6

60

55

50

45

40

5

4

3

2

35

1

30

25

0

0

2

4

6

Time,h

8

10

12

15

2

4

6

Time,h

8

10

12

250

Alkalis in solution

C

14

Adsorption capacity, mg/g

12

11

10

Adsorption capacity of pellets GZS

D

240

13

Concentration, % mass

0

230

220

210

200

9

190

8

7

180

0

2

4

6

Time,h

8

10

12

0

2

4

6

Time,h

8

10

12

-10

15

13

12

11

10

9

8

0

x 10

Effective diffusion coefficient in pellets GZS

F

2.9

Effective diffusion coefficient, m.sq/s

Mechanical strength, Kgf

14

3

Mechanical strength of pellets GZS

E

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2

2

4

6

Time,h

8

10

12

0

2

4

6

Time,h

8

10

12

Optimization of caustic treatment processes of zeolite’s sorbents

5

Figure 2. Kinetics of output vatiables of GZS caustic treatment process

The obtained values of components contents in granulated sorbent have been used to

calculate adsorption and mechanical properties of zeolite sorbent (Figures 2D-2F) in

accordance with mathematical models described above.

The adequacy of the developed model has been proved through comparison of modeling

results and experimental data. F- criterion with 5% significance level was used as a

criterion of adequacy of the developed model. Results of determination of F- criterion

for all output variables proved its changes within 1.01 to 1.64 interval with F= 2,36.

4. Solution of process parameters optimization problem for the caustic

treatment of GZS under uncertainty

Statement and solution of optimization problem of GZS caustic treatment were

preconditioned by the following factors. As a rule, the cost price of GZS is significantly

lower than the saving rate of its implementation. For example, using drying cartridges in

refrigerator sets reduces the possibility of throttling device freezing to a minimum,

subsequently lowering the risk of compressor breakdown. At the same time, the costs of

drying agent and refrigerator sets are incomparable. With a view to that, we have used a

dependency between adsorption and mechanical properties of GZS (such as maximum

adsorption volume W0 , effective diffusion coefficient D e 0,5 , and mechanical strength

of granules P ) instead of product cost prices when stating the goal function of

optimization problem.

Taking this into account the problem of optimization is stated as follows: for a given

type of GZS (percentage and type of claying agent, shape and size of granules,

calcinating conditions) such conditions of caustic treatment should be selected

(concentration of caustic solution Сi , temperature of caustic solution t i , mixer speed

n i , and mass balance between liquid and solid phases in the unit i ) that the value of

goal function with consideration to adsorption and mechanical properties of GZS

( W 0 , De0,5 , P ) reaches its maximum:

1

1 1 P P D De0 ,5 W0i W0

max

Y ( P , De0 ,5 ,W0 ) k P k D kW0 i 0 ei0 ,5

W0

De0 ,5

0 e0 ,5 0 0 P0

for the constraints

kP , kD

e0 ,5

2... 3 Ci 10... 15; 45 ti 105; 0 ni 300; 1 7,

(6)

where

, kW0 0 at

( Pi P0 ) / P0 0 , ( Dei0 ,5 De0 ,5 ) / De0 ,5 0, ( W0i W0 ) / W0 0 ; P0 , W0 , De0,5 are

minimal admissible values of GZS adsorption and mechanical properties. In this case

the stated problem was solved on the condition of fulfillment of chemical content

requirements ( Si / Al ratio) for a clay coupling agent with probability of no less than

80%.

The maximum of the goal function was computed by means of sequential quadratic

programming. Having solved the stated optimization problem, we have determined

optimal conditions of caustic treatment of GZS industrial sample NaA-2ММ-Т. Optimal

values of process parameters of experimental unit were found to be the following:

6

A. Ermakov et al.

Сi (NaOH) - 15 % mass.; ti - 105 С; ni - 150 rotations per minute; i - 2,5. The results

of comparing adsorption and mechanical properties of caustic treated GZS in optimal

conditions and in conditions according to current technical regulations are presented in

Table 1.

Table 1. Adsorption and mechanical properties of GZS

Parameter

Parameter value

Computed

In practice

1,28

1,33

0,191

0,193

11,5

11,4

1,32

1,39

0,215

0,220

15,1

15,6

Technical regulations

De 1010, m2/s

W0 103, m3kg-1

P, kgs/granule

Optimal conditions

De 1010, m2/s

W0 103, m3kg-1

P, kgs/granule

5. Conclusion

Mathematical model of GZS caustic treatment process has been developed. The

problem of process parameters optimization with regard to 80 % probability constraint

on chemical content of clay coupling agent ( Si / Al ratio) has been solved. Introduction

of caustic treatment stage into zeolite 4A sample production in optimal conditions has

proved to increase the following adsorption and mechanical properties of zeolite

sorbents: mechanical strength by 36,8 %, adsorption capacity by 14%, and effective

diffusion coefficient by 4,3%.

References

Ermakov A., 2003, Kinetics and optimization of GZS caustic treatment process (in Russian),

Ph.D.-thesis, Tambov, Russia.

Ermakov A., D. Dvoretsky, S. Dvoretsky, 2007, Mathematical modeling of caustic treatment

processes of zeolites sorbents // European Congress of Chemical Engineering (ECCE-6), Book of

Abstracts, pp. 613-614.