Experiments - p61-142

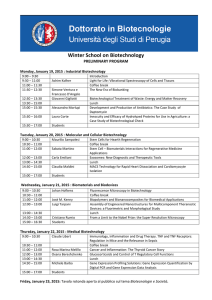

advertisement