R55_11_14-Proposal_worst case_2015_…

advertisement

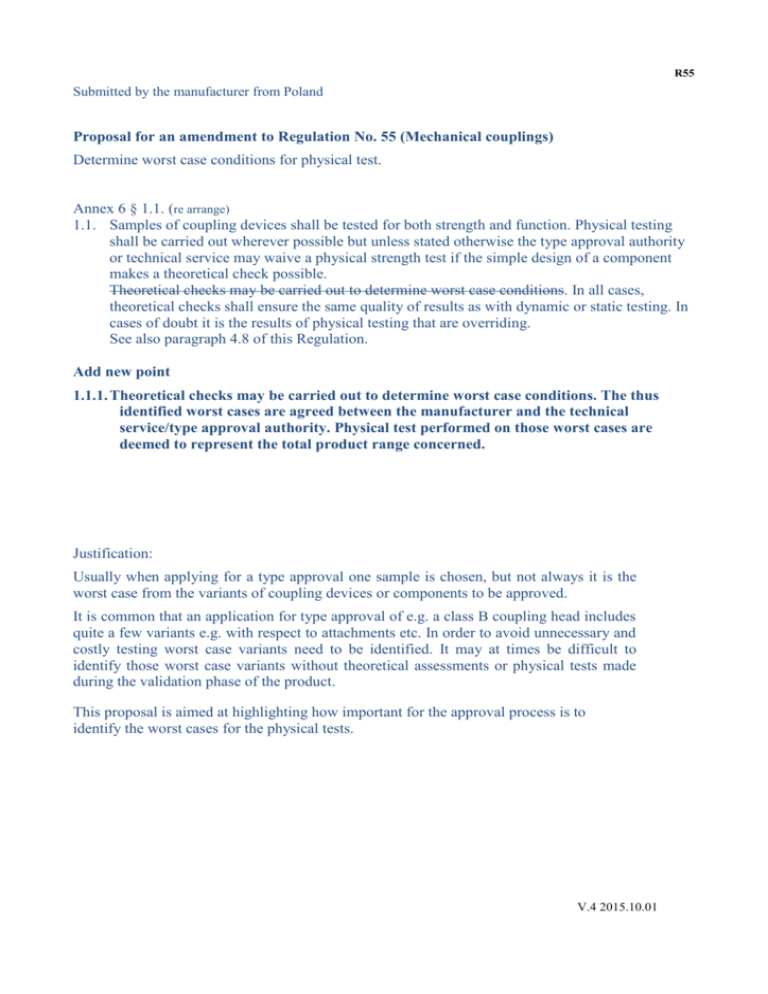

R55 Submitted by the manufacturer from Poland Proposal for an amendment to Regulation No. 55 (Mechanical couplings) Determine worst case conditions for physical test. Annex 6 § 1.1. (re arrange) 1.1. Samples of coupling devices shall be tested for both strength and function. Physical testing shall be carried out wherever possible but unless stated otherwise the type approval authority or technical service may waive a physical strength test if the simple design of a component makes a theoretical check possible. Theoretical checks may be carried out to determine worst case conditions. In all cases, theoretical checks shall ensure the same quality of results as with dynamic or static testing. In cases of doubt it is the results of physical testing that are overriding. See also paragraph 4.8 of this Regulation. Add new point 1.1.1. Theoretical checks may be carried out to determine worst case conditions. The thus identified worst cases are agreed between the manufacturer and the technical service/type approval authority. Physical test performed on those worst cases are deemed to represent the total product range concerned. Justification: Usually when applying for a type approval one sample is chosen, but not always it is the worst case from the variants of coupling devices or components to be approved. It is common that an application for type approval of e.g. a class B coupling head includes quite a few variants e.g. with respect to attachments etc. In order to avoid unnecessary and costly testing worst case variants need to be identified. It may at times be difficult to identify those worst case variants without theoretical assessments or physical tests made during the validation phase of the product. This proposal is aimed at highlighting how important for the approval process is to identify the worst cases for the physical tests. V.4 2015.10.01