A PROPERTY OWNERSHIP TRANSFER SYSTEM

advertisement

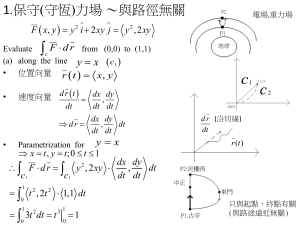

1 A METHOD OF FABRICATING A FIBER COUPLER FIELD OF INVENTION 5 The present invention relates to a method of fabricating a fiber coupler. BACKGROUND OF INVENTION Electric field propagation in fiber couplers still faces the problem of polarization. The 10 effects of these polarizations are that there are still losses experienced during propagation which could have been redirected to improve efficiency. There is therefore a need for improvements on reducing polarization in fiber couplers. 2 SUMMARY OF INVENTION Accordingly there is provided a method of fabricating a fiber coupler, the method includes the steps of positioning 3 single mode fibers on a plurality of stages, 5 connecting the fibers to a diode laser and displaying to a photodiode, wherein the two fibers are twistable and held by vacuum means, fusing and pulling of the fibers, heating of the coupling regions and stopping the heating and pulling upon reaching a preset coupling ratio. 10 The present invention consists of several novel features and a combination of parts hereinafter fully described and illustrated in the accompanying description and drawings, it being understood that various changes in the details may be made without departing from the scope of the invention or sacrificing any of the advantages of the present invention. 15 3 BRIEF DESCRIPTION OF THE DRAWINGS The present invention will be fully understood from the detailed description given herein below and the accompanying drawings which are given by way of illustration 5 only, and thus are not limitative of the present invention, wherein: Figure 1 shows a block diagram for an experimental set up for a method of fabricating a fiber coupler in a preferred embodiment of the invention; Figure 2 shows a block diagram of Measurement of Polarization at the output ports 3X3 SMF coupler in the preferred embodiment of the invention; 10 Figure 3 illustrates a graphical representation of power transfer between the three waveguides with variable coupling coefficient; Figure 4 illustrates a graphical representation of power input being distributed symmetrically to the two outer waveguide (WG 1 and WG 3); and Figure 5 illustrates a graphical representation of decreasing output powers versus 15 different angles of polarization. 4 DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT The present invention relates to a method of fabricating a fiber coupler. A detailed description of a preferred embodiment of the invention is disclosed herein. It should be 5 understood, however, that the disclosed preferred embodiment is merely exemplary of the invention, which may be embodied in various forms. Therefore, the details disclosed herein are not to be interpreted as limiting, but merely as the basis for the claims and for teaching one skilled in the art of the invention. 10 The following detailed description of the preferred embodiment will now be described in accordance with the attached drawings, either individually or in combination. Figure 1 shows an experimental set up for a method of fabricating a fiber coupler. The method includes the steps of positioning 3 single mode fibers on a plurality of stages, 15 connecting the fibers to a diode laser and displaying to a photodiode, wherein the two fibers are twistable and held by vacuum means, fusing and pulling of the fibers, heating of the coupling regions and stopping the heating and pulling upon reaching a preset coupling ratio. The method is carried out by placing three single mode fibers (SMF) on the stages. Corning fiber with diameter of core and cladding 125 and 8.2 micrometer 20 respectively, is connected to the diode laser and displayed to the photodiode. The two fibers are twisted and held by a vacuum system with both ends. All parameters are recorded by data acquisition card installed to the computer system. The initial step is to pre-set parameters such as coupling ratio, maximum pulling 25 length, x-y-z position of torch flame, and flowing of H2 gas. 1 mW laser launched to the one of input ports is detected by photo detector and kept for calibration, while the fusion and pulling process are started. During the step of the torch flame heating the 5 coupling region, the fibers are elongated by pulling stages with suitable pulling speed of 100µm/s. Heating and pulling process will be automatically stopped when the preset coupling ratio is reached. For safety reason, the coupling region is saved and packaged. The mechanical operation is motorized in micrometers scale. 5 A next set up of fused 3X3 Single Mode Fiber (SMF) coupler is designed to investigate polarization characteristics as shown in Figure 2. Continuous Wave (CW) laser as an optical source is launched to an outer fiber (fiber 3) with wavelength operation of 1550 nm. A laser beam is polarized by different angle of polarizer before moving at one of 10 outer fiber (Waveguide 3). Optical Spectrum Analyzer (OSA) and Optical Power Meter (OPM) are set to detect the power at three output ports of 3X3 fiber coupler. Propagation of optical power in silica-fiber waveguide coupler described by coupled mode theory shows the strength of the coupling coefficient to transfer power from a waveguide to other waveguide. The propagation of optical power significantly depends 15 on separation between fibers axis at coupled region. Since a 3X3 SMF coupler successfully fabricated with waveguides are weakly coupled, the fiber cross section and separation are nearly identical, powers detected at output ports will be normalized. However, the transfer power between the waveguides is different for not only every configuration or arrangement of that three fibers joined, but also which input port fed by 20 power. With this method, linear arrangements of three waveguides at coupling region are purposed. Power is launched to outer waveguide (WG 1 or WG 3), the power transfer between three waveguides can be determined from matrix transform which is given by (4) in two conditions. The first condition, power is launched in to waveguide 1 or waveguide 3 as 6 a linear order. By substituting A1 (0) 1, and A2 (0) A3 (0) 0 in (4) as shown in Figure 3 yields as follow. (6a) (6b) 5 (6c) The propagation of optical power in silica-fiber waveguide coupler described by coupled mode theory shows the strength of the coupling coefficient to transfer power from a waveguide to other waveguide. It significantly depends on separation between fibers axis at coupled region. Since a 3X3 SMF coupler successfully fabricated with 10 waveguides are weakly coupled, the fiber cross section and separation are nearly identical, powers detected at output ports will be normalized. However, the transfer power between the waveguides is different for not only every configuration or arrangement of that three fibers joined, but also which input port fed by power. In this paper, linear arrangements of three waveguides at coupling region are purposed. 15 Power P1 propagates gradually from initial waveguide (WG 1) to the center waveguide (WG 2). Power P2 affected by the coupling coefficient 23 , will optimize it at waveguide 3 (fiber 3). The second condition, input power is fed in the center of the three waveguides .Similarly by substituting A2 (0) 1, and A1 (0) A3 (0) 0 in (4), will yield as follow: A1 z A3 z j 20 1 sin 2 z e j z 2 (7a) 7 A2 z cos 2 z e j z (7b) Figure 4 shows that power input will be distributed symmetrically to the two outer waveguide (WG 1 and WG 3). Power P2 is minimum. Polarization is a factor that affects the sensitivity and stability of the optical network 5 system, especially for the passive device of fiber optics systems, polarization may cause losses in that device. It is possible to a fiber coupler to have significant losses caused by polarization effects. determined from the coupled-mode theory. By rewriting the differential matrix for MXN fiber coupler as (8), where electric field for the 10 ith Ai ( z ) , and Ai (0) are the output powers and input powers respectively. A1 ( z ) B C1 0 . . . A ( z) C B C 0 . . 1 2 1 A3 ( z ) 0 C1 B C1 0 . d . j . . . . . . dz . . . . . . . . . . . . . . A (Z ) 0 . . . 0 C1 M 0 A1 (0) . A2 (0) . A3 (0) . . . . 0 . B AN (0) (8) Every amplitudes has two component vector polarization, they are x and y component. x B xy Defining xy y ixjx C1 ixjy is matrix of coupling for single fiber, and matrix of coupling between two adjacent fibers. Where ixjy iyjy is the ixjx iyjy , and ixjy are the two x polarization modes, and two y -polarization modes, and x and y polarized modes 15 of two adjacent fibers of coupling coefficients respectively. Consider all fibers, which are identically isolated and weakly coupled, have different polarization, and the coupling coefficient of this mode ixjy is assumed zero. The 8 coupling coefficients ixjx xx iyjy yy assumed 5 x A1x ( z ) xy A1 y ( z ) A ( z) ixjx 2x 0 A2 y ( z ) A3 x ( z ) d A3 y ( z ) j dz . . . AMx ( z ) A ( z) My between and xy y two identical modes of polarization are xx = yy = . Eq. 1 can be given as, ixjx 0 A1x (0) A1 y (0) 0 x xy ixjx 0 A2 x (0) 0 . . . A2 y (0) iyjy xy y 0 iyjy 0 x xy ixjx 0 A3 x (0) ixjx 0 . . 0 A (0) 0 iyjy xy y 0 iyjy 3y . . . . . . . . . . . . . . . . . . . . . . . 0 0 x xy ANx (0) ixjx 0 . . . 0 A (0) 0 iyjy xy y Ny 0 iyjy 0 . . . 0 (9) or, it can be simplified in term of transpose matrix describing the matrix transmission of the MXN fiber coupler including the two polarized modes. E 1x 10 E1 y E2 x T E1x E2 y E1 y E3 x E2 x E3 y E2 y . . . EMx E3 x EMy z t E3 y . . . EMx EMy t (10) The polarization characteristics of single mode fiber coupler can be investigated by applying matrix (1), then inserting the boundary condition to the calculation. In this research, the polarization characteristic of 3X3 are purposed to be investigated. To examine the polarization behavior of 3X3 SMF coupler, it is simplified three fibers are 15 in linear arrangement. Consider the coupling coefficient given by (5) is held to be constant along the fiber, and the coupling region is very short, it can be simplified x2 2 x y y2 4 xy2 2 20 2 1 , x y , and . Using matrix equation of polarization of multiport fiber coupler given by (9), Eq. 5 becomes. 9 T e i x y 2 L M1 M 2 M 3 M2 M4 M2 1 L L sin 2 cos 1 L 1 cos 2 i 2 2 2 2 M1 i xy L sin 2 cos 1 L 1 2 2 M2 5 (11) i xy * 1 2 L 2 L i sin cos 1 L 1 cos 2 2 2 2 2 xy 2 L 2 L 2 L 2 sin 1 L sin i cos sin 1 L sin 2 2 2 2 2 2 * 2 2 xy 2 L 2 L 2 L sin 1 L sin sin 1 L sin i cos 2 2 2 2 2 2 1 L L sin 2 cos 1 L 1 cos 2 i 2 2 2 2 M3 i L xy sin 2 cos 1 L 1 2 2 M4 M3 M 2 M1 2 i xy sin 2 L 2 cos 1L 1 * 1 2 L 2 L i sin cos 1 L 1 cos 2 2 2 2 2 xy 2 L 2 L 2 L 2 sin 1 L sin i cos sin 1 L sin 2 2 2 2 2 2 * 2 2 xy 2 L 2 L 2 L sin 1 L sin sin 1 L sin i cos 2 2 2 2 2 2 2 sin 2 L 2 cos 1L 1 The Eq. 11 depends on where the input power is launched. For example, if the input power to the center (fiber 2), the output power at fiber 1 and fiber 3 given by following equation. 2 4 xy L L 1 2 sin 1 L sin 2 2 cos 2 2 2 2 2 2 xy 2 2 2 L S2 sin L sin 1 2 22 2 xy L L 2 2 2 2 S3 sin L sin cos 1 2 2 22 (12) S1 Figure 5 shows a good agreement among output power in both three output ports 10 decreases exponentially by increasing the angle of polarization in (12). However, Initial power at P1 is slightly higher than power at P2 and P3. This is a weakness of 3X3 as a power splitter since the coupled region is linear arrangement. P2 and P3 are held identical and similar power. 10 A directional fiber coupler is fabricated with the method as described above. The fiber coupler which has an identical-output ratio is successfully fabricated by heating the coupling region with fusion temperature of 800-1350 °C. The coupled-mode theory has been used to model power transfer between the waveguides based on transfer matrix 5 method. By launching 1mW input power to one of three input ports, it shows that power propagation among three coupled fibers is always normalized if the waveguides are nearly identical and have same separation between them. This constructed matrix 3x3 also has been used to determine the polarization behavior of directional fiber coupler. It is found that incident beam polarized at different angle causes power output at both 10 three output ports decrease exponentially. It is to be understood that the embodiments of the invention described are exchangeable for other variations of the same in order to be used in various applications. The present embodiment of the invention is intended for, but not restricted to, use as a passive device that can be used as power splitter and routers. 15