Lab 2 - DC motor

advertisement

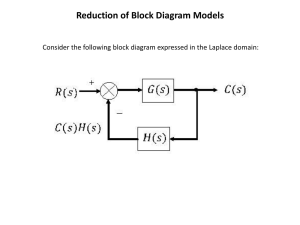

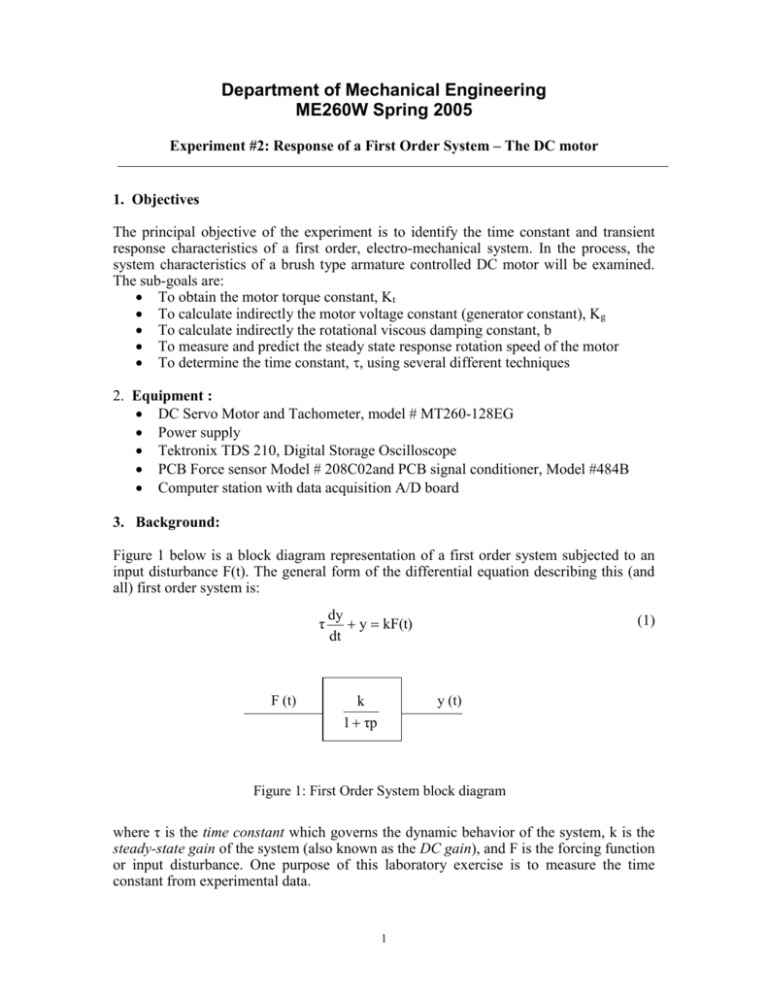

Department of Mechanical Engineering ME260W Spring 2005 Experiment #2: Response of a First Order System – The DC motor 1. Objectives The principal objective of the experiment is to identify the time constant and transient response characteristics of a first order, electro-mechanical system. In the process, the system characteristics of a brush type armature controlled DC motor will be examined. The sub-goals are: To obtain the motor torque constant, Kt To calculate indirectly the motor voltage constant (generator constant), Kg To calculate indirectly the rotational viscous damping constant, b To measure and predict the steady state response rotation speed of the motor To determine the time constant, , using several different techniques 2. Equipment : DC Servo Motor and Tachometer, model # MT260-128EG Power supply Tektronix TDS 210, Digital Storage Oscilloscope PCB Force sensor Model # 208C02and PCB signal conditioner, Model #484B Computer station with data acquisition A/D board 3. Background: Figure 1 below is a block diagram representation of a first order system subjected to an input disturbance F(t). The general form of the differential equation describing this (and all) first order system is: τ F (t) dy y kF(t) dt (1) y (t) k 1 τp Figure 1: First Order System block diagram where τ is the time constant which governs the dynamic behavior of the system, k is the steady-state gain of the system (also known as the DC gain), and F is the forcing function or input disturbance. One purpose of this laboratory exercise is to measure the time constant from experimental data. 1 Consider the response of a system described by equation (1) to a step-input disturbance. The forcing (or input) function is given as: F(t) X u(t) (2a) where X is a constant and u(t) is the Heaviside step function given by 0 u(t) 1 for t 0 for t 0 (2b) The response to this input is: t y(t) Y 1 e τ where the steady-state response magnitude is given by Y = k X (k = DC gain). (3) will be extracted in three different ways: 1) The step response of the system is shown in Figure 2. Several key aspects of the response are also labeled. The first of these aspects is referred to as the 63.2% response point, which is obtained when t/τ = 1. This is the point where; y(t τ) (1 e 1 ) 0.632 (4) Y This means that the response y(t) is at 63.2% of the final steady-state value Y. Thus, the time constant can be quickly determined, if the point at which the response at 63.2% of its steady-state value is estimated quickly. 1 0.9 0.8 y(t)/Y 0.7 0.632 0.6 0.5 0.4 0.3 0.2 t1 τ 0.1 0 0 1 t/ t1 1 τ 2 Figure 2: Step response of a first order system 2 3 2) The time constant of the system can also be identified by calculating the slope of the response, i.e. the derivative of the response with respect to time. Taking the derivative of the response (equation (3)) yields an expression for the slope of the response at any given time: dy Y t τ e dt τ (5) This slope can be used to write an expression for a line tangent to the curve at any point in time. This tangent line has the form - t1 y(t) Y1 - e Y t1 τ e τ (t t 1 ) (6) where t1 is the time at which the tangent line is drawn. As illustrated in Figure 2, the tangent intersects with the steady-state value Y at a time, sec later t t1 τ (7) This provides a second means for evaluating the time constant, as this behavior is common to all first order systems. In other words, if the slope of the response curve at any arbitrary time is extrapolated to intersect with the asymptotic response, the intersection will take place time units after the point the tangent was taken. These two methods, the 63.2% response point and tangent intersection point, are two quick ways to estimate the time response of the system. 3) If the experimental data are scattered, or if the steady-state value is unknown it may be difficult to identify the 63.2% response point. Taking the derivative of the response to evaluate the time constant via the intersection method is also prone to problems, because experimental slopes will be highly sensitive to variations in data. A more rigorous way to determine the time constant is to perform linear regression on the data. This is accomplished by rearranging equation (3) as: y(t) t e τ Y Taking the natural log of both sides will result in an equation that is linear in time: 1- 1 y(t) ln 1 t Y τ (8) (9) Considering time as the independent variable and the entire left-hand side as the dependent variable, this is a linear relationship that can be used to determine the time constant via linear regression. After the transformation, the data will fall on a straight line as shown in Figure 3. When the data is treated in this manner, the fitted line is constrained to pass through the origin (since there is only one fitting constant!) and has a slope equal to the reciprocal of the time constant. 3 t 0 ln(1-y/Y) 1 τ 1 Modeling a DC Figure 3: Semioflog plotMotor of theSystem step response An armature controlled DC motor is given schematically in Figure 4. An input voltage, ei, is provided by an external power supply. The motor possesses an internal resistance, R, and an inductance, L. This inductance is a result of the electromagnetic effect developed by the armature windings, and has a negligible effect for most times of interest. The shaft of the motor and driven component (a disk in the present lab) have an inherent rotational inertia, J. The system also experiences viscous damping, characterized by the coefficient b, due to internal and air damping. A mathematical model of this motor can be developed by considering the electrical and mechanical constituents of the system separately. The following equation describes the armature circuit: ei R i K g Ω (10) where ei is the voltage applied to the armature, R is the resistance of the windings, i is the current, Kg is the motor voltage constant (or generator constant) and Ω is the angular velocity of the motor shaft. The last term of equation (10) is commonly called the back emf developed within the motor - it is a reverse voltage proportional to the angular speed of the shaft. (Note: this characteristic is inherent because of the motor's capability to act as a generator as well as a motor. That is, if the shaft was turned by an alternative source (e.g. water), the same armature could be used to generate electricity.) R ei L b J ei T, Figure 4: Schematic of the test setup 4 The output torque T developed at the armature shaft is proportional to the armature current, i.e. (11) T Kt i This provides a connection between the mechanical response of the set-up and the electrical behavior of the motor. (The two motor constants, Kt, and Kg are actually equal to one another, though details of this connection will not be presented here.) In this particular set-up, the output torque is used to overcome the motor inertia and frictional drag. If the frictional drag is viscous in nature, the equilibrium equation of the rotor system is: dΩ TJ bΩ (12) dt where J is the inertia of the rotating parts, and b is the rotational viscous damping coefficient. A composite block diagram of equations (10)-(12) is shown in Figure 5. The symbol p is the differential operator and is equivalent to differentiation with respect to time. Thus, the input to this system is the voltage potential ei applied to the armature, and the response is the angular velocity Ω. Equations (10)-(12) can be combined (eliminating T and i) to produce one differential equation which describes the combined electromechanical response of the system: dΩ τ Ω k ei (13a) dt where the time constant of the system is given by τ b J KtKg (13b) R and the steady-state gain is given by k ei + - 1 (13c) bR Kg Kt 1 R Kt Kg Fig. 5: A simplified block diagram 5 1 Jpb R’ R b Motor ei Tachometer e0 =K J Load To x-y plotter Figure 6: Free rotation test Equation (13a) is a first order differential equation in the standard form. The time constant τ is representative of the response speed of the system, and the gain constant k dictates the steady-state sensitivity behavior between the system output and input. 5. General Strategy for Parameter Evaluation: In order for the above equations to be utilized in simulating the system, it is necessary to collect sufficient data to determine the system parameters, e.g. Kt, b, Kg, etc. In this section, a general strategy for obtaining the system parameters is outlined. A detailed procedure is given in the subsequent section. Block rotor test (to determine Kt): If the motor armature is locked (i.e. prevented from rotating) and a voltage potential ei is applied, the output torque is still related to the armature current by Equation (11). The armature current can be varied by introducing additional resistances in series into the armature circuit, as shown in Figure 6. The corresponding motor torque is measured by a suitably mounted force transducer. The motor torque constant Kt is obtained by plotting the output torque vs. current (T vs. i) data. The slope is Kt. CAUTION: In order to not burn out the armature windings, it is important to obtain the experimental data as quickly as possible. Free speed test (to determine Kg and b): Recall that the gain constant is simply a ratio of the output speed to input voltage: ei 1 bR Kg Kt . (13c) Furthermore, this gain depends on the resistance of the circuitry involved. Using a single resistor in series with the internal resistance of the motor, the steady state speed can be 6 measured (recall that ei = 24 volts in all cases). Substituting the known values for R, Kt, ei, and the measured output into equation (13c) leaves one equation for two unknowns (Kg and b). Using a different resistor in the circuit will produce a different steady state rotation speed. Substituting these new values into equation (13c) gives a second equation for the same two unknowns. A more graphical approach is to rewrite equation (13c) as b ei R. K g (14) Kt Plotting the aforementioned data using this equation it becomes evident that the intercept is Kg, the motor constant. Also, the slope is a combination of b and Kt. This is shown graphically in Figure 7. ei b 1 Kt Kg 0 R Figure 7: Test for determining b & Kg Transient test: The differential equation that describes the behavior of the DC motor is of first order. Measuring the time constant of the system, will be accomplished using the three techniques described in section 3. Furthermore, once the time constant is determined, the rotary inertia to be determined by rearranging the Equation (13b); Kt Kg J τ b 1 bR 5. Experimental Procedure: The overall experimental setup is shown schematically in Figure 8. 7 (15) DC Motor SCXI Chassis Power Supply Signal Conditioner Computer Figure 8: Experimental Apparatus Blocked Rotor Test Unhook the wires running from the power supply to the motor. Using a digital multimeter, verify that the input voltage is 24 volts. With the same multimeter, measure the internal resistance across the motor. Reattach the motor to the power supply. Attach the moment arm to the load (the disk), and bring it into contact with the force transducer such that it blocks the armature from rotation. The PCB power supply for the force transducer should be adjusted to have a gain of 1 (see back of the power supply). Rotate the armature away from the force transducer and adjust the dial indicator on the front of the PCB power supply, until the load recorded by LabView is zero. This zeros out the force transducer. Rotate the disk until the armature once again contacts the force transducer. With no external resistance in the armature circuit (flip the switch to 0 ohms), turn on the circuit and record the resulting torque (this is done in LabView). This test should be carried out as quickly as possible to avoid overheating of the motor. Note that the force transducer actually puts out a voltage. However, there is a supplier provided calibration constant between the output voltage and the force. Multiplying this force by the moment arm of the armature gives the resulting torque. This is all done internally for you in the LabView routine. The current supplied to the motor may be calculate using i ei R (16) where ei and R are known. Knowing the supplied current and the output torque, the motor constant Kt may be determined using equation (11). Free Speed Test Carefully disengage the moment arm from the load. With no external resistance in the circuit (leave the switch at 0 ohms), apply DC power to the circuit and wait until the motor reaches its steady-state speed. Record this speed. Turn the power supply off and let the motor come to a stop. Now add a 1-ohm resistor in series with the motor resistance by flipping the resistance switch to “1 ohm”. Start the motor up again and allow it to come to steady state. Record this new rotation speed. Knowing the values of the steady 8 state speed and the additional resistance, equation (14) may be used to determine the unknown motor generator constant Kg and the viscous damping constant b. Repeat this procedure several times and create a plot similar to that shown in Figure 7. Compare your Kg with your Kt obtained from the blocked motor test, both in value and in units. Discuss the reasons if they are different. Transient test Record the transient time response of the motor during start-up. Do this test twice – once having no resistor in series with the motor and once with the 1 ohm resistor in series with the motor. From these results, determine the time constant of the system using the three methods described previously. Also determine the net moment of inertia of the system. Note that the mass moment of inertia of the combined system is made up of the motor armature, the tachometer armature and the installed rotor. 7. Acquiring Test Data using LabView Exercise 1: Block rotor test (to determine motor torque constant Kt): In this exercise, the force1102.VI is used to determine the motor stall torque. The force1102.VI front panel is shown in Figure A1. After setting the parameters on the front panel of the VI, attach the moment arm to the flywheel, and bring it to contact the force transducer such that it blocks the armature from rotation. Set the DC power supply to 24 volts and leave this setting through the entire test sequence. With no external resistance in the armature circuit, turn on the circuit and recording the resulting force. Use the data acquisition system and run the force1102VI. After sampling the signal from the accelerometer for a predetermined length of time, the sampled signal is displayed and the resulting force and the corresponding voltage can be found. Make sure your workstation is set up in the following manner: 1. Open the VI. (c:\me260w\lab5 _SDOF lab\force1102.vi) 2. Make sure the SCXI chassis is turned on. 3. Press the Save data button on the VI front panel (Option). This stores the data in a file. 4. Set the following parameters on the VI: Sample rate: as desired (e.g.1024) Samples: as desired (e.g. 1024) Device:1 Channels :ob0!sc1md2!0 5. Run button in the top left corner of the VI. 9 Exercise 2: Free speed test (to determine the motor generator constant Kg and the viscous damping constant b): Carefully disengage the moment arm from the load. With no external resistance in the circuit, apply DC power to the circuit and wait until a steady-state speed of the motor is obtained. Repeat this test for various armature resistances. Calculate the resulting gain constant k. The rpm 1102.VI lets you measure motor rpm and the tachometer voltage. Figure 2A is the front panel of the rpm1102.VI. The steps required for taking a tachometer voltage measurement are provided. Read through them carefully and do not be afraid to try things on the device. If you have a question after trying things on your own, contact your instructor. Taking Measurements: Make sure your workstation is set up in the following manner: 1. Open the VI. (c:\me260w\lab5_SDOF lab\rpm1102.vi) 2. Make sure the SCXI chassis is turned on. 3. Press the Save data button on the VI front panel (Option). This stores the data in an array. Set the following parameters on the VI: Device: 1 Channels: ob0!sc1md2!0:1 Sample rate: as desired (e.g. 10240) Scans: as desired (e.g. 10240) Filter: on Filter type: low pass (select it only if the filter is ON) Windows: None Filter type: select as desired (non, low pass filter, high pass filter, band pass) Low cut off: 20 High cut off: 50 4. Run button in the top left corner of the VI. 10 1st Order Motor Tests number of samples sample rate 1000.00 Plot 0 Voltage channel (0) device Save 1 1 5000 OFF Plot 0 Force 0.3 5.0 4.5 4.0 3.5 0.2 3.0 2.5 2.0 0.1 1.5 1.0 0.5 0.0 0.0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 sec 5.0 0.0 0.5 1.0 1.5 2.0 Cursor 0 0.34 0.08 Cursor 0 0.52 17.61 Cursor 1 0.00 -0.01 Cursor 1 0.34 0.00 Figure A1: The force1102.VI front panel. SDOF LAB2 Figure A2: The rpm1102.VI front panel. 11 2.5 3.0 3.5 4.0 4.5 sec 5.0