New forward scatter visibility sensor for RVR application

advertisement

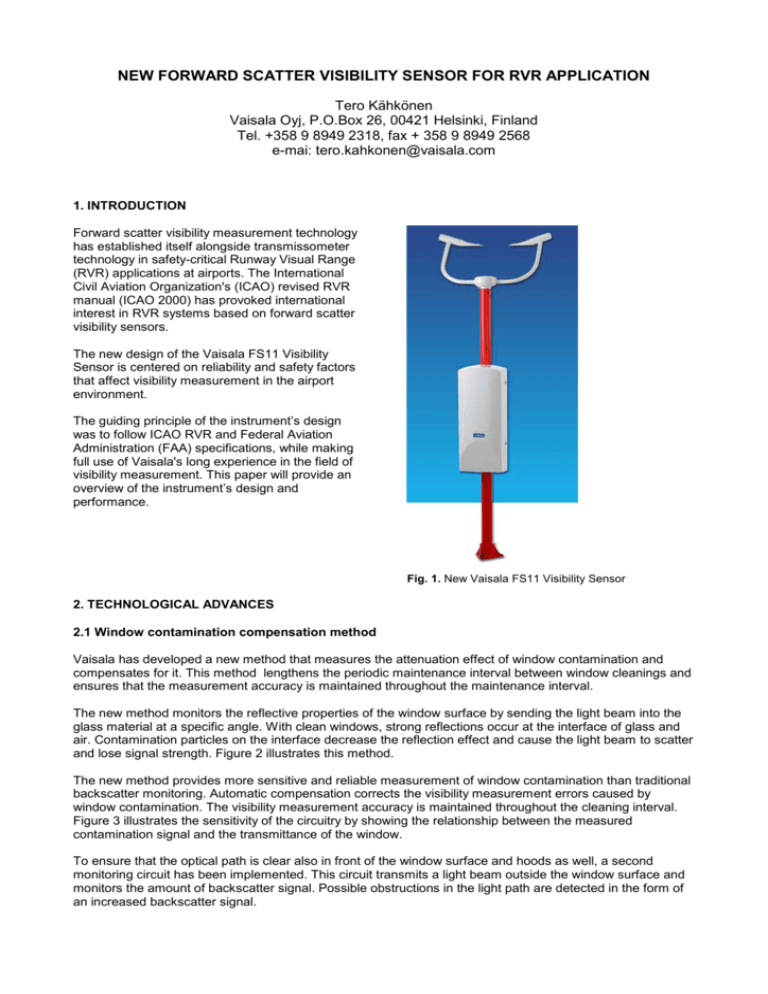

NEW FORWARD SCATTER VISIBILITY SENSOR FOR RVR APPLICATION Tero Kähkönen Vaisala Oyj, P.O.Box 26, 00421 Helsinki, Finland Tel. +358 9 8949 2318, fax + 358 9 8949 2568 e-mai: tero.kahkonen@vaisala.com 1. INTRODUCTION Forward scatter visibility measurement technology has established itself alongside transmissometer technology in safety-critical Runway Visual Range (RVR) applications at airports. The International Civil Aviation Organization's (ICAO) revised RVR manual (ICAO 2000) has provoked international interest in RVR systems based on forward scatter visibility sensors. The new design of the Vaisala FS11 Visibility Sensor is centered on reliability and safety factors that affect visibility measurement in the airport environment. The guiding principle of the instrument’s design was to follow ICAO RVR and Federal Aviation Administration (FAA) specifications, while making full use of Vaisala's long experience in the field of visibility measurement. This paper will provide an overview of the instrument’s design and performance. Fig. 1. New Vaisala FS11 Visibility Sensor 2. TECHNOLOGICAL ADVANCES 2.1 Window contamination compensation method Vaisala has developed a new method that measures the attenuation effect of window contamination and compensates for it. This method lengthens the periodic maintenance interval between window cleanings and ensures that the measurement accuracy is maintained throughout the maintenance interval. The new method monitors the reflective properties of the window surface by sending the light beam into the glass material at a specific angle. With clean windows, strong reflections occur at the interface of glass and air. Contamination particles on the interface decrease the reflection effect and cause the light beam to scatter and lose signal strength. Figure 2 illustrates this method. The new method provides more sensitive and reliable measurement of window contamination than traditional backscatter monitoring. Automatic compensation corrects the visibility measurement errors caused by window contamination. The visibility measurement accuracy is maintained throughout the cleaning interval. Figure 3 illustrates the sensitivity of the circuitry by showing the relationship between the measured contamination signal and the transmittance of the window. To ensure that the optical path is clear also in front of the window surface and hoods as well, a second monitoring circuit has been implemented. This circuit transmits a light beam outside the window surface and monitors the amount of backscatter signal. Possible obstructions in the light path are detected in the form of an increased backscatter signal. Lens Reflecting light beam Transmitter LED 100% 80% 60% 40% 20% 0% 0% 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 % 10 0% Window Window transmittance Detector Normalized contamination measurement signal Fig. 2. Optical configuration of window contamination measurement circuitry Fig. 3. Relationship between the measured contamination signal and the transmittance of the window 2.2 Reliable operation in harsh weather conditions The FS11’s low maintenance requirement is a result of the new window contamination measurement and compensation system, its weatherproof head-down design and high-power heaters. The mechanical optical head design and head-down configuration provide very efficient protection against all windblown particles. The optical surfaces are even protected from particles flying horizontally. The high-power heaters, with individual temperature monitoring and control, ensure that snow does not accumulate on the optical heads even during severe snowstorms. The open mechanical design minimizes the shadowing effect on the sample volume. This ensures that wind direction related errors do not appear in the visibility measurement results. Also, the measurement sample volume has been moved away from the parts that generate heat to ensure correct results in calm wind situations. According the ICAO RVR manual, a forward scatter meter may underestimate RVR in rain by up to a factor of two if the rain events are not identified and the underestimation is not taken into account. The optical and electrical design of the FS11 ensures reliable individual rain droplet detection from the measurement signal. The effect of rain droplets on the extinction coefficient is calculated separately. This provides accurate results during rain events. Fig. 4. The head-down design of the optical heads Fig. 5. Optical head with high-capacity heating element 2.3 Safety and reliability To fulfill airport frangibility requirements, the FS11 is equipped with an approved frangible composite mast structure that is designed to break when subjected to collision forces. The mast construction has been impact tested and verified to show compliance with ICAO year 2005 design criteria for frangibility. A built-in UPS system has been implemented to ensure reliable and uninterrupted operation during mains power outages.. The sophisticated self-diagnostics and modular design allow for very short mean time to repair (MTTR). The measurement fork and background luminance sensor are separate, intelligent instruments with their own processors and parameter memories. Both the visibility sensor measurement unit and the background luminance sensor can be replaced quickly as pre-calibrated spare parts without on-site calibration. This means very short down time in case of trouble. 2.4 Scientifically valid chain of calibration The accuracy of the FS11 is ensured by a two-point calibration procedure. The first point is a zero scatter signal, which is produced by blocking the receiver completely. The second point is a high scatter signal, which is produced with a reference scatterer. The scattering response of the calibration device can be traced to a reference FS11 visibility sensor, which is in continuous operation at the Vaisala outdoor test field along with reference transmissometers and other instrumentation. This FS11 reference unit has been calibrated by verifying its output values against those of the Vaisala reference transmissometer under various fog and precipitation conditions. The measurement accuracy of the FS11 in the field depends on how well the calibrated response of the reference FS11 can be transferred to the field devices. To define the best possible configuration for the reference scatterers, Vaisala undertook a development program that included extensive study of possible sources of error that could appear during annual field calibration. The study exploited optical design simulation programs that allowed the researchers to quantify the variations between the design parameters relating to calibrator devices. Based on this study, it was found that the most stable and repeatable calibration result could be achieved with a calibration method whereby two opaque glass plates of the same size are placed in parallel, at a distance that is relatively wide in comparison to their diameter. This calibration method is the most tolerant of small mechanical differences in plate locations and angles. The figure 7 illustrates the design of the reference scatterer device. It also shows the mask plates that are used to verify the correctness of the measurement beam geometry. Reference transmissometers FS11 sensors Test field A set of FS11 sensors is calibrated against reference sensors Calibrator This calibration is transferred to production units with a calibration device Production units Fig. 6. Calibration chain of the FS11 Visibility Sensor Fig. 7. FS11 with reference scatterer device 3. TEST RESULTS Performance and verification testing of the FS11 was carried out over 2001-2002. Comparison tests were carried out against the reference transmissometer, which verified that the new Vaisala FS11 Visibility Sensor fulfills ICAO and FAA requirements relating to the RVR application. Figures 8 and 9 provide an overview of the FS11’s measurement performance. The ICAO RVR manual recommends that the box plot format be used for test result presentation. Therefore, the results below are expressed as box plots which show the distribution of ratios of meteorological optical range (MOR) between the test and reference sensor for different bins of MOR. MOR values are in the y-axis. The MOR ratios between the FS11 and the reference transmissometer are in the x-axis. Figure 8 illustrates the concordance of the FS11’s measurement with the reference transmissometer. Figure 9 illustrates the degree of measurement consistency between two FS11 units. Fig 8. Example of a box plot diagram from comparison testing of the FS11 against reference transmissometer Fig 9. Example of a box plot diagram from the comparison testing of two FS11units 4. CONCLUSIONS The new Vaisala FS11 Visibility Sensor fulfills FAA and ICAO requirements for the demanding and safetycritical RVR application. Technological advances in mechanical design, a new measurement and compensation method for window contamination, and calibration consistency ensure correct visibility information and high data availability even during harsh weather conditions. The FS11 is also accurate in conditions of high visibility, up to a range of 75 km, making it suitable for aeronautical and SYNOP visibility measurement purposes. 5. REFERENCES Manual of Runway Visual Range observing and reporting practices, Second edition-2000, Doc 9328-AN/908, International Civil Aviation Organization Runway Visual range System, Federal Aviation Administration Specification, FAA-E.2772, Oct 11, 1996