AE 569

advertisement

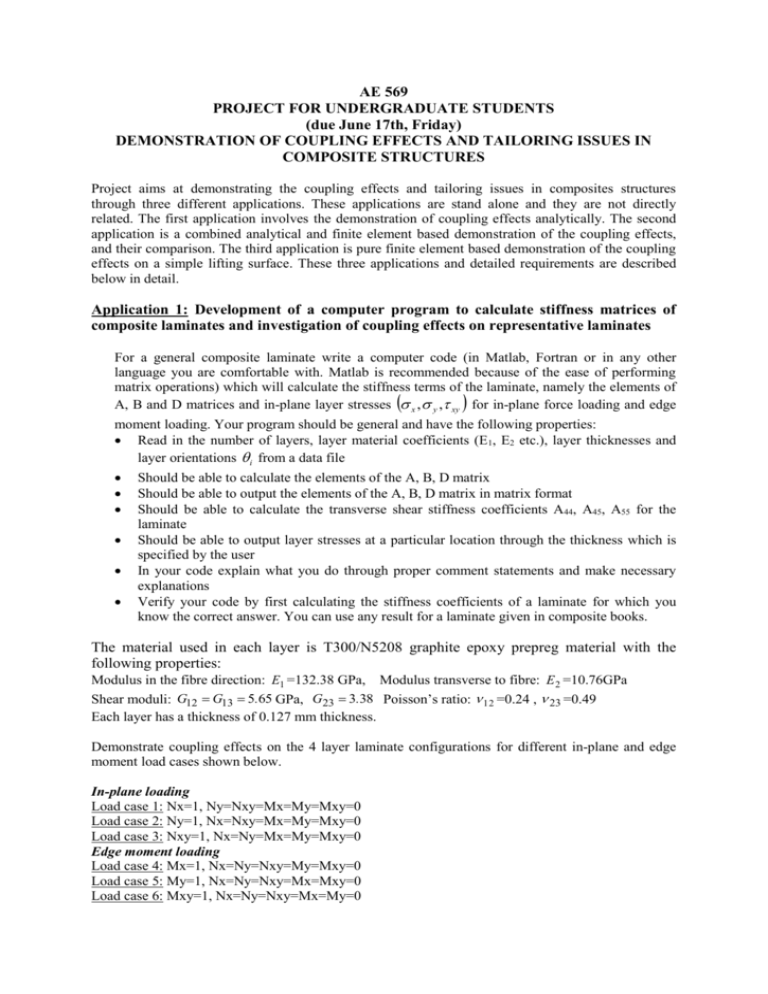

AE 569 PROJECT FOR UNDERGRADUATE STUDENTS (due June 17th, Friday) DEMONSTRATION OF COUPLING EFFECTS AND TAILORING ISSUES IN COMPOSITE STRUCTURES Project aims at demonstrating the coupling effects and tailoring issues in composites structures through three different applications. These applications are stand alone and they are not directly related. The first application involves the demonstration of coupling effects analytically. The second application is a combined analytical and finite element based demonstration of the coupling effects, and their comparison. The third application is pure finite element based demonstration of the coupling effects on a simple lifting surface. These three applications and detailed requirements are described below in detail. Application 1: Development of a computer program to calculate stiffness matrices of composite laminates and investigation of coupling effects on representative laminates For a general composite laminate write a computer code (in Matlab, Fortran or in any other language you are comfortable with. Matlab is recommended because of the ease of performing matrix operations) which will calculate the stiffness terms of the laminate, namely the elements of A, B and D matrices and in-plane layer stresses x , y , xy for in-plane force loading and edge moment loading. Your program should be general and have the following properties: Read in the number of layers, layer material coefficients (E1, E2 etc.), layer thicknesses and layer orientations i from a data file Should be able to calculate the elements of the A, B, D matrix Should be able to output the elements of the A, B, D matrix in matrix format Should be able to calculate the transverse shear stiffness coefficients A44, A45, A55 for the laminate Should be able to output layer stresses at a particular location through the thickness which is specified by the user In your code explain what you do through proper comment statements and make necessary explanations Verify your code by first calculating the stiffness coefficients of a laminate for which you know the correct answer. You can use any result for a laminate given in composite books. The material used in each layer is T300/N5208 graphite epoxy prepreg material with the following properties: Modulus in the fibre direction: E1 =132.38 GPa, Modulus transverse to fibre: E 2 =10.76GPa Shear moduli: G12 G13 5.65 GPa, G23 3.38 Poisson’s ratio: 12 =0.24 , 23 =0.49 Each layer has a thickness of 0.127 mm thickness. Demonstrate coupling effects on the 4 layer laminate configurations for different in-plane and edge moment load cases shown below. In-plane loading Load case 1: Nx=1, Ny=Nxy=Mx=My=Mxy=0 Load case 2: Ny=1, Nx=Nxy=Mx=My=Mxy=0 Load case 3: Nxy=1, Nx=Ny=Mx=My=Mxy=0 Edge moment loading Load case 4: Mx=1, Nx=Ny=Nxy=My=Mxy=0 Load case 5: My=1, Nx=Ny=Nxy=Mx=Mxy=0 Load case 6: Mxy=1, Nx=Ny=Nxy=Mx=My=0 In-plane loading Edge moment loading z z Mxy Ny My a x b y x Mx Nx y Nxy Mxy For the six load cases given above, make a table, as shown below, which will show the type of coupling and magnitude of the coupling which is measured in terms of either as mid-plane strains or curvatures. Note that you need to invert the stiffness matrices in each case. Therefore, Matlab is recommended as the tool to use in performing the calculations. An example is given below. In the coupling effect column, the first term corresponds load and the second term corresponds to the coupling effect. If there is more than one coupling effect list them one after another. For each load case, try to identify the laminate configurations with the most severe coupling effect. For instance, [x(bottom layer)/x/x/x (top layer)] has the most severe bending-twisting coupling etc. For one of the laminate configurations, which exhibit the most severe coupling effect, determine the in-plane stresses at the mid-plane of the top layer. Ex: Load case: 4 In-plane stresses in midLaminate configurations Coupling effect Magnitude ( xo,yo,xyo, x ,y ,xy ) plane of the top layer of one of the laminate which exhibits most severe coupling 0/0/0/0 None - Bending-twisting xy = xxx e-04 - 90/0/0/90 0/90/90/0 0/90/0/90 90/0/90/0 +45/-45/+45/-45 x =aaa , y =bbb , xy =ccc 90/45/0/-45 45/45/45/45 -45/-45/-45/-45 The aim of the first application is to familiarize you with the coupling effects. You can insert additional laminate configurations to the tables as you wish. Application 2: Investigation of extensional-bending coupling effect on axially loaded beams For the simply supported beam under axial loading shown below determine: i) The lay-up configuration of four layered laminates which will give the most severe extensionalbending coupling effect analytically. Follow the example we solved in class and modify it as necessary (We will complete this example after we finish the strength and failure of laminates section. In the mean time you can prepare your FE model and perform sample runs). In other words, find the configuration which will give the highest lateral displacement for the in plane loading shown below. You can use the output of the first application in deciding on the laminate configuration which will result in the most severe extensional-bending coupling. This part may require either intelligent guessing or writing a code which will determine the laminate configuration which will maximize the lateral deflection (for instance peak deflection –decide on this yourself). Determine the axial and lateral displacement for the configuration which gives the most severe extensional-bending coupling. ii) For the configuration which gives the most severe extensional-bending coupling, determine the axial and lateral displacement field by the finite element solution. Model the beam in Patran and carry out FE solution. Give the vertical displacement plot. Compare with the analytical solution given in part i. iii) For the configuration which gives the most severe extensional-bending coupling, determine the axial stresses at x=L/2 at the mid-planes of the layers by the analytical solution and finite element solution and compare them. z,w GIVEN: h x,u P=80 N L Geometric properties: Beam length, L: 20 cm, Thickness, h=1.5 mm, Width, b:10 mm Material properties: High modulus graphite epoxy Modulus in the fibre direction: E1 =207.35GPa, Modulus transverse to fibre: E 2 =5.18GPa Shear moduli: G12 G13 G23 3.11 GPa, Poisson’s ratio: 12 =0.25 Stacking sequence of the laminate: (to be decided by you [L1/L2/L3/L4] ) Thickness of each layer: 0.375 mm Note: Model the beam by shell elements, not beam elements Application 3: Investigation of the bending-twisting coupling effect on swept wings In this application a swept forward flat plate wing will be investigated in terms of coupling bending and twisting deformation. For this purpose, the rectangular flat plate wing shown below will be analyzed. It is assumed that wing is connected to fuselage through front and rear spar connection as shown by the light blue numbers. Front and rear spar fuselage connections prevent three translations displacements. In addition, front spar-fuselage connection also prevents rolling motion (y axis rotation). Assume that flat plate wing is composed of four layers which are made of high modulus graphite epoxy with the material properties given below. Free stream Rear spar 1m Front spar 1m 3m Forward swept flat plate wing Material properties: High modulus graphite epoxy Modulus in the fibre direction: E1 =207.35GPa, Modulus transverse to fibre: E 2 =5.18GPa Shear moduli: G12 G13 G23 3.11 GPa, Poisson’s ratio: 12 =0.25 Layer thicknesses: 5 mm Note: In practice a 3 mm long flat plate with 4 mm thickness will be very flexible. Spars and stringers would be needed to provide rigidity. However, for the purpose of demonstrating the coupling effects we will only model the flat plate. Loading on the wing: The loading acting on the wing is simplified as shown below. It is assumed that on the strip between the leading edge and the mid-chord a uniform pressure of 100 Pa is acting, and on the strip between the mid-chord and the trailing edge a uniform pressure of 50 Pa is acting, as shown in the figure below. These figures are arbitrary and in a real situation realistic air loading must be used. Free stream Free stream Pressure distribution acting on the wing Objective: The objective of the third application is to come up with a stacking sequence (for the flat plate wing with 4 layers) which will eliminate the twist induced due to bending. For the base configuration, define material orientation in the x direction as shown below and assign 0 degree for the layer orientations (which means that the base configuration has layers oriented in the direction of the material orientation vector shown below). i) For the base forward swept wing configuration determine the twist distribution along the wing by calculating the twist by using the vertical deflections of the nodes along the same chord-line on the leading and trailing edges, as shown in the first figure on the next page. Note that in the finite element solution there will be slight effect of chord-wise bending. To see that chord-wise bending effect is very small, draw pictures of the vertical deflection versus chord-wise position at three different wing span locations. Draw conclusions on the adverse effects of bending-twisting coupling on the aeroelastic behaviour of the flat plate wing. ii) Determine the twist distribution for the unswept and backward swept wings. Use the same loading for comparison purposes. Draw conclusions on the effect of bending-twisting coupling for forward/backward swept and unswept wings. (Note that such bending twisting coupling that you observe in the swept wings is not due to the use of composite material. Isotropic materials would also exhibit bending-twisting coupling) iii) In the figures below sample results are given for two different lay-ups which show different twist effect. In this part come up with a stacking sequence which will eliminate the twist due to bending for the forward swept wing. You can do several trial and errors or read the input text file (.bdf) modify the stacking sequences automatically and perform several Nastran runs to come up with a stacking sequence which will eliminate the twist. Or, you can use the code you have written in the first application to decide on the stacking sequence which will eliminate the bending twisting coupling. High bending-twisting coupling iv) Low bending-twisting coupling For the stacking sequence you have determined in part iii, make two additional runs on the unswept and backward swept wings. Comment on the effect of the lay-up used on the bending-twisting coupling effect. Also comment on how you would use bending-twisting coupling effect (in general) to gain advantage for unswept and backward swept wings. Assume that you are designing a composite airplane and you want to use the effect of bending-twisting coupling to help you with some aspects of your design. Give one or more examples.