Chaotic Pendulum

advertisement

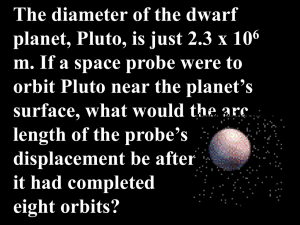

Characterization and Analysis of a Chaotic Pendulum H. Potter (Completed 8 March 2006) A chaotic pendulum was characterized by determining its natural frequency, its damping, and its driving torque. These parameters were then used to predict, measure, and compare resonance curves. Chaotic motion was then observed by increasing drive torque and decreasing drive frequency. Two Poincare plots were produced using this data so that the presence of strange attractors could be observed. I. Introduction Periodic phenomena are commonplace, and in an effort to better understand more complex periodicity it is fruitful to study controlled periodic motion. This experiment does so by studying the periodic motion of a mechanical chaotic pendulum. A small mass that is attached to a shaft, as well as all other instruments attached to this shaft, is the body undergoing periodic motion. An optical shaft encoder-disc that is attached to the shaft and rotates with the mass transmits data to a computer where data analysis can be completed. Also attached to the shaft is a ring magnet that, in combination with a non-rotating copper plate, provides damping through eddy current losses as the apparatus rotates1. The separation between the copper plate and the ring magnet can be adjusted accurately using a micrometer that is mechanically linked to the copper plate. A motor provides a driving force with an adjustable frequency and amplitude. By adjusting the specifics of the motion, such as the driving frequency, driving amplitude, damping, and orientation, those factors that affect the motion can be controlled. This makes it possible to determine the parameters of the pendulum’s motion experimentally. This experiment has five distinct, but related sections. In the first section the natural frequency of the pendulum is calculated by measuring the change in its period as it is released from various initial angles. In the second section the damping associated with various micrometer spacings is recorded and a calibration curve relating micrometer spacing to damping is created. In the third section the torque produced by applying various voltages to the motor is observed for several micrometer spacings, and this data is used to create conversion curves between applied voltage and resultant torque for these micrometer spacings. Section four uses the previously acquired data in order to create expected resonance curves for five different quality factors. Data is then recorded so that a comparison can be made between the expected and actual resonance curves. The final section explores the appearance of chaotic motion when the driving frequency is lowered significantly as the driving amplitude is increased. II. Section 1: Natural Frequency The procedure for determining the pendulum’s natural frequency is as follows. As the initial angular displacement of the pendulum mass increases, the period of its motion after it is released increases exponentially, assuming that the motion is relatively undisturbed by damping. Thus the micrometer spacing was increased as much as possible in order to minimize the effects of damping on the motion. By recording the period for a number of different initial displacements, a data set can be obtained that is large and varied enough to make an exponential regression somewhat reliable. By extrapolating this curve back to a zero initial angular displacement, an experimental value for the natural period of the pendulum can be obtained. It is critical that several data points with very large initial angular displacements are included in the data set; otherwise, it may be concluded incorrectly that the period does not depend on initial angular displacement because it increases so slowly at first. Including data points with higher initial angular displacements also helps to distinguish the appropriate exponential fit from the inappropriate linear fit. The apparatus used in this experiment records angular position and velocity at .007ms intervals. The data was exported to Microsoft Excel, and the number of cells separating the first two angular position zeroes were recorded. This number was then multiplied by the interval duration and doubled in order to yield a value for the full pendulum period. The initial angular displacement of each run was also recorded from the exported data set. These data pairs were then plotted and an exponential regression was performed in order to determine the pendulum’s natural period. The natural frequency of the pendulum was then calculated using 0 2 . P0 (1) Pendulum Period Period (s) 1.0 y = 0.6427e0.1386x R2 = 0.9844 0.9 0.8 0.7 0.6 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Initial Angle (rad) Figure 1: A plot of all data recorded along with the equation of the exponential regression, and the corresponding r2 value. 2 Data Summary: Interval Size (s) 0.007 Data: Run Number 1 2 3 4 5 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 P0 (s) 0.6427 ω0 (s) 9.7762 r2 0.9844 θm (rad) Intervals Passed Period (s) 1.3100 54 0.756 1.3383 55 0.770 1.0643 53 0.742 0.6860 50 0.700 1.0776 53 0.742 1.2488 54 0.756 0.8796 52 0.728 0.7477 51 0.714 0.8196 51 0.714 1.1765 53 0.742 1.2771 54 0.756 1.0425 54 0.756 1.0556 53 0.742 0.9189 52 0.728 0.9833 53 0.742 0.7728 51 0.714 0.9173 52 0.728 1.1272 53 0.742 0.9629 52 0.728 0.6479 52 0.728 0.7524 52 0.728 0.9959 53 0.742 0.9519 52 0.728 1.0524 53 0.742 0.8743 52 0.728 1.0069 52 0.728 0.9550 53 0.742 0.9269 52 0.728 0.9849 53 0.742 1.0085 53 0.742 0.9158 53 0.742 1.0037 53 0.742 0.8969 52 0.728 1.0430 53 0.742 2.5400 66 0.924 2.5180 66 0.924 2.6986 67 0.938 2.5918 67 0.938 2.6405 66 0.924 2.5730 65 0.910 2.6185 65 0.910 2.6012 66 0.924 Table 1: All data recorded that was plotted in order to determine the natural period of the pendulum, with the exception of runs 6 through 8, which were recognized as being unreliable due to very small initial angular displacements. 3 III. Section 2: Damping Calibration The equation of a harmonic oscillator is, in general, d 2 d I 2 b mgr sin T , dt dt (2) or, in a more convenient form for this experiment, d 2 b d mgr sin T , I I dt 2 I dt (3) where θ is the angular displacement, I is the moment of inertia of the entire rotating portion of the apparatus, b is the damping coefficient, m is the mass of the actual pendulum bob, r is the distance of the bob from the shaft (from the axis of rotation), g is the acceleration due to gravity, and T is the torque produced by the driving motor. In order to isolate the damping term in Equation 3, the entire chaotic pendulum was turned on its side and clamped into place so that the gravitational term no longer affected the pendulum’s motion, and the driving motor was turned off. This left only the first two terms in Equation 3 to consider. This portion can be easily solved for angular velocity to yield i e b t I , (4) where ωi is the initial angular velocity given to the pendulum. Thus, by giving the pendulum an initial angular velocity, the rate at which it slows was observed in order to determine the damping, b/I. It was most prudent to consider this decay in its logarithmic form so that a linear regression on the data set yielded a line that had a slope equal to b/I. Thus the graph of b ln i t I (5) was considered and a linear regression was performed on it in order to determine b/I directly for each data set. By collecting data for a range of micrometer spacings, a calibration curve was obtained so that the damping associated with any micrometer spacing could be determined. This fit was exponential, as is shown in Figure 2. 4 Run 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 ωi (rad/s) 42.225 46.833 39.645 37.485 55.171 55.667 49.403 49.838 54.939 58.826 62.859 56.565 69.250 66.066 74.939 57.075 44.302 μ (mm) b/I (rad/s) 13.00 0.474 13.00 0.4733 13.00 0.4839 13.00 0.4852 12.50 0.5153 12.00 0.6367 11.50 0.7743 11.00 1.0103 10.50 1.1603 10.00 1.4382 9.50 1.8907 9.00 2.3826 8.50 3.3434 8.00 4.3677 7.50 5.7392 7.00 8.009 6.50 10.682 r2 0.999 0.9995 0.9988 0.9988 0.9956 0.9907 0.995 0.9913 0.9976 0.9984 0.9983 0.9998 0.9988 0.9994 0.9992 0.9989 0.9977 Table 2: All data used in determining the exponential calibration curve for damping as a function of micrometer spacing. Damping Calibration Curve Damping, b/I (rad/s) 12 y = 181.09e-0.4661x R2 = 0.9872 10 8 6 4 2 0 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 Micrometer Setting (mm) Figure 2: A graph of the data collected along with the exponential fit to the data. Use Curve to Determine Damping: y=aebx μ (mm) b/I (rad/s) a 8.50 3.4458 181.09 9.00 2.7294 r2 b 9.50 2.1620 0.9872 -0.4661 10.00 1.7126 10.50 1.3565 Table 3: The exponential curve is used here to determine the damping for the 5 micrometer spacings that will be used in later sections. 5 IV. Section 3: Voltage to Torque Conversion In this section another special case of Equation 3 is considered. Rather than isolate damping, as was done in Section 2, it was desired that torque should be isolated. In order to accomplish this, the entire apparatus was again clamped in position on its side so that its motion is entirely perpendicular to the vertical, and thus unaffected by gravitational forces. In order to render the second derivative term negligible, the torque was controlled by adjusting an outside direct current voltage supply that was connected to the motor. For any given voltage, the driving torque should be constant, and thus the mass will spin around very rapidly, but will approach a terminal velocity very quickly as well. Once it reached terminal velocity, the second order term vanished. By measuring this terminal angular velocity, the torque, T/I, was calculated as T b t , (6) I I where ωt is the terminal angular velocity and b/I is known from Section 2. As voltage increases, terminal velocity increases linearly for intermediate voltages; however, nonlinearlity leads to inaccurate extrapolation for values that are either much lower than those observed, or above a certain threshold voltage, above which terminal velocity stops increasing. It is highly recommended, therefore, that the experimenter determine as precisely as possible the voltage range over which the calibration curve will be used before proceeding. In this experiment the terminal velocity was taken to be the average of all data points exported that were not well outside a reasonable range, and thus simply due to mechanical errors. After sifting through the data for these points, which were relatively rare, but typically so different from the normal values that they skewed the average angular velocity, the average of all values recorded for each run was taken to be the terminal velocity for that run. Voltage was then increased incrementally and another data set was recorded. This process continued until a voltage of approximately 4 volts was applied, at which point the micrometer spacing was changed and the process repeated. It was observed, upon analyzing the data, that although the lower micrometer spacings had higher maximum terminal velocities, the linear portions of all calibration curves laid on the same line. Thus, all data points that were in the linear portions of the various calibration curves were combined in order to yield a single linear calibration curve. If the voltages involved in Section 4 were in this linear portion of the combined calibration curve, then a normal linear regression would be appropriate for determining the torque produced by voltages in this range; however, the voltages involved in Section 4 are well below the voltage range of the data. As a result, the nonlinearity of the calibration curve near the origin becomes very significant. In order to accommodate this fact as best as possible given the available data, the combined linear regression was made to pass through the origin. The fit to the data was still reasonable, but not as good; however, this change enabled a rough approximation of the torque produced at the much lower voltages, and was thus quite useful and appropriate. It is this linear fit that is shown in Figure 3. All other calibration curves are displayed in their entirety for comparative purposes and qualitative analysis by the reader. 6 Torque, T/I (rad/s 2) Voltage to Torque Conversion, Combined Linear Data Set 300 250 200 150 100 50 0 y = 258.81x R2 = 0.927 0.0 0.2 0.4 0.6 0.8 1.0 Voltage (V) Figure 3: The regression line was forced through the origin in order to better approximate torques corresponding to very small voltages, as was necessary for Section 4. μ (mm) Voltage to Torque Conversion, 8.50mm 250 Torque, T/I (rad/s 2) 8.50 2 Voltage (V) ωt (rad/s) T/I (rad/s ) 0.333 19.088 65.774 0.485 29.718 102.400 0.538 34.351 118.364 0.660 43.703 150.590 0.788 52.881 182.215 0.938 61.485 211.862 1.043 63.983 220.468 1.262 66.145 227.921 1.649 66.503 229.154 1.856 66.285 228.404 2.047 65.416 225.409 2.216 65.781 226.664 2.446 65.115 224.372 2.828 64.366 221.790 3.245 63.845 219.993 3.690 63.252 217.951 4.050 62.407 215.039 4.950 60.866 209.731 200 150 100 50 0 0 1 2 3 4 5 Voltage (V) Table 3 and Figure 4: Data for 8.50mm micrometer spacing. 7 μ (mm) Voltage to Torque Conversion, 9.00mm 300 Torque, T/I (rad/s 2) 9.00 2 Voltage (V) ωt (rad/s) T/I (rad/s ) 0.351 27.235 74.335 0.463 38.922 106.234 0.594 53.116 144.976 0.660 58.787 160.456 0.742 67.305 183.705 0.838 76.671 209.268 0.956 83.672 228.377 1.123 87.723 239.433 1.431 88.785 242.333 1.638 88.887 242.610 1.949 88.335 241.103 2.145 88.116 240.507 2.373 87.407 238.572 2.580 87.264 238.181 3.141 85.785 234.145 3.528 85.322 232.881 3.827 83.983 229.225 4.230 82.592 225.430 250 200 150 100 50 0 0 1 2 3 4 5 Voltage (V) Table 4 and Figure 5: Data for 9.00mm micrometer spacing. μ (mm) Voltage to Torque Conversion, 9.50mm 300 Torque, T/I (rad/s 2) 9.50 2 Voltage (V) ωt (rad/s) T/I (rad/s ) 0.307 34.954 75.571 0.485 59.046 127.658 0.638 79.099 171.013 0.746 93.629 202.429 0.832 103.092 222.887 0.969 108.268 234.078 1.173 110.103 238.045 1.284 110.071 237.976 1.550 110.813 239.580 1.796 110.429 238.750 2.106 110.139 238.123 2.342 110.324 238.523 2.559 109.869 237.539 2.897 109.695 237.163 3.160 109.451 236.636 3.494 108.398 234.359 3.817 108.407 234.378 4.030 108.569 234.729 250 200 150 100 50 0 0 1 2 3 4 5 Voltage (V) Table 5 and Figure 6: Data for 9.50mm micrometer spacing. 8 μ (mm) Voltage to Torque Conversion, 10.00mm 300 Torque, T/I (rad/s 2) 10.00 2 Voltage (V) ωt (rad/s) T/I (rad/s ) 0.293 43.077 73.771 0.333 51.618 88.399 0.474 68.868 117.941 0.550 86.415 147.992 0.686 109.197 187.007 0.770 113.876 195.020 0.958 147.662 252.881 1.116 152.812 261.701 1.348 154.112 263.927 1.559 155.805 266.827 1.884 154.034 263.794 2.200 153.548 262.961 2.679 151.248 259.023 2.989 150.922 258.464 3.322 149.420 255.892 3.580 148.682 254.628 4.020 148.311 253.993 250 200 150 100 50 0 0 1 2 3 4 5 Voltage (V) Table 6 and Figure 7: Data for 10.00mm micrometer spacing. μ (mm) Voltage to Torque Conversion, 10.50mm 300 Torque, T/I (rad/s 2) 10.50 2 Voltage (V) ωt (rad/s) T/I (rad/s ) 0.250 46.881 63.596 0.368 76.850 104.251 0.440 94.375 128.024 0.570 125.112 169.721 0.629 138.826 188.324 0.786 169.006 229.265 0.895 184.777 250.659 0.960 192.297 260.860 1.118 200.416 271.874 1.274 201.369 273.167 1.466 203.966 276.690 1.604 203.269 275.744 1.928 200.748 272.325 2.371 200.735 272.307 2.684 198.036 268.646 3.173 193.384 262.335 3.509 191.456 259.719 3.936 188.512 255.726 250 200 150 100 50 0 0 1 2 3 4 5 Voltage (V) Table 7 and Figure 8: Data for 10.50mm micrometer spacing. V. Section 4: Resonance Curves In order to analyze resonance phenomena, the driving motor was connected to an alternating current power supply with an adjustable driving frequency. This enabled the effect of driving frequency on oscillation amplitude to be observed and analyzed. The responsiveness of amplitude to changes in driving frequency is measured by the quality factor Q of the particular oscillator. It is defined by 9 Q 0 b I . (7) The reason that this definition is appropriate is directly related to the fact that m T I 2 0 2 2 2 , (8) b 2 I where θm is the maximum angular displacement of the oscillator. The larger that b/I is relative to ω0, the less the value of ω relative to ω0 affects the maximum angular displacement of the oscillator. A higher quality factor, therefore, corresponds to significant resonance. Thus, by choosing to observe changes in amplitude due to changes in drive frequency for relatively weak damping, resonance curves with distinct peaks can be made by plotting the maximum angular displacement observed for a range of drive frequencies at a specific micrometer spacing. This was done for 5 different micrometer spacings, and the expected curves were plotted by using Equation 8 in combination with the results of Section 1, Section 2, and Section 3. The maximum angular displacement should be at a maximum when 2 1b , 2I 2 0 (9) so it is interesting to note that all of the graphs have distinct peaks at lower drive frequency than this formula would predict. This suggests that the natural frequency calculated in Section 1 is somewhat high, and thus that the natural period calculated was somewhat low. In addition, all of the graphs of expected maximum displacement are well below those that were observed. This can be attributed to the extreme extrapolation that was required in order to estimate the torque at such low voltages. More voltagespecific calibration in Section 3 would remedy this problem if a steady source of such small voltages could be found, and if the alternating voltage supplied by the driving motor was more consistent. Typically it would oscillate throughout a 10mV range. For the purposes of determining torque the average of the upper and lower extremes was taken to be the effective voltage. 10 Expected Largest Max Angular Displacement (rad): 9.468 2 μ (mm) Q Voltage (V) T/I (rad/s ) 8.50 2.84 0.011 2.847 θE (rad) f (Hz) ω (rad/s) θm (rad) 0.765 4.807 0.423 0.038 0.829 5.209 0.435 0.040 0.911 5.724 0.447 0.043 1.059 6.654 0.507 0.051 1.161 7.295 0.588 0.058 1.282 8.055 0.664 0.069 1.396 8.771 0.548 0.080 1.447 9.092 0.503 0.084 1.560 9.802 0.459 0.084 1.733 10.889 0.364 0.065 1.920 12.064 0.280 0.044 2.030 12.755 0.247 0.035 2.161 13.578 0.217 0.028 2.300 14.451 0.180 0.023 Table 8: Resonance data for 8.50mm micrometer spacing. Maximum Angular Displacement (rad) Resonance Curve, Q=2.84 0.7 0.6 0.5 0.4 θm (rad) θE (rad) 0.3 0.2 0.1 0.0 4 6 8 10 12 14 Angular Driving Frequency (rad/s) Figure 9: Resonance data for 8.50mm micrometer spacing. 11 Expected Largest Max Angular Displacement (rad): 9.584 2 μ (mm) Q Voltage (V) T/I (rad/s ) 9.00 3.58 0.0115 2.976 θE (rad) f (Hz) ω (rad/s) θm (rad) 0.770 4.838 0.307 0.041 0.838 5.265 0.322 0.043 0.955 6.000 0.358 0.048 1.083 6.805 0.418 0.057 1.139 7.157 0.439 0.061 1.228 7.716 0.493 0.071 1.392 8.746 0.469 0.097 1.596 10.028 0.344 0.107 1.704 10.707 0.294 0.085 1.881 11.819 0.217 0.054 2.028 12.742 0.181 0.040 2.132 13.396 0.161 0.033 2.282 14.338 0.134 0.025 2.352 14.778 0.126 0.023 Table 9: Resonance data for 9.00mm micrometer spacing. Resonance Curve, Q=3.58 Maximum Angular Displacement (rad) 0.6 0.5 0.4 θm (rad) 0.3 θE (rad) 0.2 0.1 0.0 4 6 8 10 12 14 Angular Driving Frequency (rad/s) Figure 10: Resonance data for 9.00mm micrometer spacing. 12 Expected Largest Max Angular Displacement (rad): 9.656 2 μ (mm) Q Voltage (V) T/I (rad/s ) 9.50 4.52 0.0165 4.271 θE (rad) f (Hz) ω (rad/s) θm (rad) 0.734 4.612 0.302 0.057 0.798 5.014 0.338 0.060 0.866 5.441 0.356 0.064 1.071 6.729 0.450 0.082 1.321 8.300 0.615 0.133 1.591 9.997 0.373 0.194 1.741 10.939 0.292 0.127 1.935 12.158 0.204 0.073 2.190 13.760 0.149 0.043 2.321 14.583 0.134 0.035 Table 10: Resonance data for 9.50mm micrometer spacing. Maximum Angular Displacement (rad) Resonance Curve, Q=4.52 0.7 0.6 0.5 0.4 θm (rad) θE (rad) 0.3 0.2 0.1 0.0 4 6 8 10 12 14 Angular Driving Frequency (rad/s) Figure 11: Resonance data for 9.50mm micrometer spacing. 13 Expected Largest Max Angular Displacement (rad): 9.701 2 μ (mm) Q Voltage (V) T/I (rad/s ) 10.00 5.71 0.017 4.400 θE (rad) f (Hz) ω (rad/s) θm (rad) 0.777 4.882 0.518 0.061 0.875 5.498 0.505 0.067 0.967 6.076 0.539 0.074 1.071 6.729 0.594 0.085 1.226 7.703 0.773 0.114 1.331 8.363 1.032 0.150 1.431 8.991 0.788 0.206 1.612 10.128 0.469 0.235 1.762 11.071 0.384 0.133 1.902 11.951 0.301 0.085 2.034 12.780 0.247 0.062 2.123 13.339 0.224 0.051 2.278 14.313 0.185 0.039 2.345 14.734 0.177 0.035 Table 11: Resonance data for 10.00mm micrometer spacing. Resonance Curve, Q=5.71 Maximum Angular Displacement (rad) 1.2 1.0 0.8 θm (rad) 0.6 θE (rad) 0.4 0.2 0.0 4 6 8 10 12 14 Angular Driving Frequency (rad/s) Figure 12: Resonance data for 10.00mm micrometer spacing. 14 Expected Largest Max Angular Displacement (rad): 9.729 2 μ (mm) Q Voltage (V) T/I (rad/s ) 10.50 7.21 0.017 4.400 θE (rad) f (Hz) ω (rad/s) θm (rad) 0.762 4.788 0.544 0.060 0.824 5.177 0.505 0.064 0.922 5.793 0.525 0.070 1.017 6.390 0.568 0.079 1.172 7.364 0.712 0.103 1.255 7.885 0.841 0.125 1.390 8.734 0.672 0.194 1.496 9.400 0.553 0.300 1.670 10.493 0.471 0.216 1.783 11.203 0.368 0.131 1.849 11.618 0.331 0.104 2.042 12.830 0.246 0.062 2.156 13.547 0.225 0.049 2.316 14.552 0.190 0.037 Table 12: Resonance data for 10.50mm micrometer spacing. Resonance Curve, Q=7.21 Maximum Angular Displacement (rad) 1.0 0.8 0.6 θm (rad) 0.4 θE (rad) 0.2 0.0 4 6 8 10 12 14 Angular Driving Frequency (rad/s) Figure 13: Resonance data for 10.50mm micrometer spacing. VI. Section 5: Chaotic Motion For sufficiently large drive frequencies and small drive amplitudes the motion of the chaotic pendulum is periodic, or at least quasi-periodic. When the amplitude is increased a great deal, however, and drive frequency is kept very small, the resulting motion of the pendulum becomes chaotic. In order to observe this chaotic motion, these conditions were put in place and a series of 5000 data points were recorded on a Poincare plot. Chaotic motion has the characteristic behavior of never repeating its motion exactly, and yet somehow having a certain tendency towards specific combinations of angular displacement and angular velocity. This behavior manifests as strange attractors 15 in a Poincare plot of the data: the points have a tendency to group together, but not coincide. This peculiar behavior can be observed in the two Poincare plots reproduced below. Chaos 1 Angular Velocity 60 40 20 0 -4 -2 -20 0 2 4 -40 -60 -80 Angle Figure 14: Poincare data plot one. Note the grouping, and yet the lack of coincidence. This type of behavior is known as being drawn to a strange attractor. 16 Chaos 2 Angular Velocity 100 50 0 -4 -2 0 2 4 -50 -100 Angle Figure 15: Poincare data plot two. Note the grouping, and yet the lack of coincidence. This type of behavior is known as being drawn to a strange attractor. VII. Conclusion This experiment involved analyzing and characterizing a chaotic pendulum very thoroughly. The first three sections involved determining the natural frequency, damping calibration curve, and torque conversion curve for the specific pendulum. These instrument-specific data were then used to investigate the more general phenomenon of resonance. A comparison was made of observed and expected resonance curves, and the predictions of the theory fell well short of accurately predicting the shapes of the resonance curves. The resonance peaks also occurred at unexpectedly low frequencies. These difficulties can be attributed to several causes. The method for determining the natural frequency of the pendulum left much to be desired in terms of leaving the experimenter confident in its quantitative accuracy. The process of finding resonance curves, however, was very reliable, and if more data were taken so that a much more continuous resonance curve could be plotted, an accurate experimental determination of the driving frequency that maximized amplitude could be made. Using Equation 9, an accurate determination of the natural frequency could be made by using the damping data from Section 2, which seemed to be very reliable. This method would correct the positions of the predicted resonance curves. In order to correct the heights of the resonance curves, a very sensitive direct current supply should be used to create a conversion curve in a more suitable voltage range. A very consistent alternating current voltage supply should then be connected to the driving motor so that the applied voltage 17 does not vary so greatly. A difficulty with this approach, however, is that the frequency of the alternating current driving would have to be determined reliably and accurately. Ultimately, by taking more data with the experience gained from this round of data collection, and by searching for ways in which to improve the methods of data collection, the quantitative accuracy of the experimental results could be vastly improved. Qualitatively, however, this data set is sufficient in order to observe the characteristic behavior of a damped, driven oscillator, including resonance. Similarly, the two Poincare plots provided help provide an intuitive understanding of the chaotic behavior at large drive amplitudes and low drive frequencies, but a more quantitative analysis would require much more time and effort. If the process of extracting each useful data point from each Excel Spreadsheet were automated the entire experiment would proceed much more quickly. Time spent collecting and analyzing data was necessarily significant due to the data collection procedure. 1 Blackburn, James A. and H. J. T. Smith, Instruction Manual for EM-50 Chaotic Pendulum. (Daedalon Corporation, Salem, MA 1998). (The source was used extensively throughout the lab report. It was only cited explicitly once, when a nearly direct quotation was used.) 18