V. Design of calibration experiments

advertisement

Design of Experiments for Calibration

of Planar Anthropomorphic Manipulators

Alexandr Klimchik1,2, Yier Wu1,2, Stephane Caro2, Anatol Pashkevich1,2.

1

Ecole des Mines de Nantes, 4 rue Alfred-Kastler, Nantes 44307, France

Institut de Recherches en Communications et en Cybernetique de Nantes, 44321 Nantes, France

alexandr.klimchik@mines-nantes.fr, yier.wu@mines-nantes.fr, stephane.caro@irccyn.ec-nantes.fr,

anatol.pashkevich@mines-nantes.fr

2

Abstract – The paper presents a novel technique for the design

of optimal calibration experiments for a planar

anthropomorphic manipulator with n degrees of freedom.

Proposed approach for selection of manipulator configurations

allows essentially improving calibration accuracy and reducing

parameter identification errors. The results are illustrated by

application examples that deal with typical anthropomorphic

manipulators.

Keywords:

calibration,

anthropomorphic manipulator

I.

design

of

experiments,

INTRODUCTION

The standard engineering practice in industrial robotics

assumes that the closed-loop control technique is applied

only on the level of servo-drives actuating the manipulator

joint variables. However, for spatial location of the endeffector, it is applied the open-loop control method that is

based on numerous computations of the direct/inverse

transformations that define correspondence between the

manipulator joint coordinates and the Cartesian coordinates

of the end-effector. This requires careful identification (i.e.

calibration) of the robot geometric parameters employed in

the control algorithm, which usually differ from their

nominal values due to manufacturing tolerances [1].

The problem of robot calibration is already well studied

and it is in the focus of research community for many

years [2]. In general, the calibration process is divided into

four sequential steps [3]: modeling, measurements,

identification and compensation. First two steps focus on

design of the appropriate (complete but non-redundant)

mathematical model and carrying out the calibration

experiments. Usually, algorithms for the third step are

developed for the identification of Denavit-Hartenberg

parameters [4], which however are not suitable for the

manipulators with collinear axis considered in this paper. For

this particular (but very common) case, Hayati [5], Stone [6],

and Zhuang [7] proposed some modifications but we will use

a more straightforward approach that is more efficient for the

planar manipulators.

Among numerous publications devoted to the robot

calibration, there is very limited number of works that

directly address the issue of the identification accuracy and

reduction of the calibration errors [8-16]. It is obviously clear

that the calibration accuracy may be improved by increasing

the number of experiments (with the factor 1 m , where m

is the experiments number). Besides, using diverse

manipulator configurations for different experiments looks

also intuitively promising and perfectly corresponds to some

basic ideas of the classical theory [17] that intends using the

factors that are distinct as much as possible. However, the

classical results are mostly obtained for very specific models

(such as linear regression) and can not be applied directly

here due to non-linearity of the relevant expressions.

In this paper, the problem of optimal design of the

calibration experiments is studied for case if a n-link planar

manipulator, which does not cover all architectures used in

practice but nevertheless allows to derive some very useful

analytical expressions and to propose some simple practical

rules defining optimal configurations with respect to the

calibration accuracy. Particular attention is given to two- and

three-link manipulators that are essential components of all

existing anthropomorphic robots.

II.

PROBLEM STATEMENT

Let us consider a general n-link planar manipulator

which geometry can be defined by equations

n

i

x li0 li ·cos q 0j q j

i 1

j 1

i

y li0 li ·sin q 0j q j

i 1

j 1

n

where ( x, y) is the end-effector position, li 0 , q j 0 are the

nominal length and angular coordinates of the i-th link and

actuator respectively, li and qi are their deviations from

nominal values, n is the number of links. Let us also

i

i

j 1

j 1

introduce notations i0 q 0j , and i q j that will

be useful for further computations. As follows from (1), the

manipulators geometrical model includes 2n parameters

{li , i , i 1, n} that must be identified by means of the

calibration.

It is assumed that each calibration experiment produces

two vectors, which define the Cartesian coordinates of the

end-effector Pi [ xi yi ]T

and corresponding joint

coordinates

Besides,

the

Qi (q1i , q2i , ... , qni ) .

measurement errors for the Cartesian coordinates ( x , y ) are

assumed to be iid (independent identically distributed)

random values with zero mean and standard deviation ,

while the measurement errors for the joint variables are

relatively small. Hence, the calibration procedure may be

treated as the best fitting of the experimental data {Qi , Pi }

by using the geometrical model (1) that leads to the standard

least-square problem. However, due to the errors in the

measurements, the desired values {li , i , i 1, n} are

always identified approximately. So, the problem of interest

is to evaluate (in the frame of the above assumption) the

identification accuracy for the parameters {li , i , i 1, n}

and to propose a technique for selecting the set of the joint

variables Qi (q1i , q2i , ... , qni ) that leads to improvement

of this accuracy (in statistical sense).

To solve this general problem, let us sequentially present

the calibration algorithm, evaluate related identification

errors and develop optimality conditions allowing minimize

the number of experiments for given accuracy in

identification of the desired parameters.

m

F

n

ll0 ll sin l0( i ) l

k i 1 l i

n

ll0 ll cos l0( i ) l

l 1

x

i

ll0 ll cos l0( i ) l

n

ll0 ll sin l0( i ) l

l 1

y 0

n

l i

i

m

F

(cos( k0(i ) k )

lk i 1

n

(ll0 ll ) cos(l0( i ) l ) xi sin( k0( i ) k )

l 1

n

(ll0 ll ) sin(l0( i ) l ) yi 0

l 1

j

where k 1, n , (j i ) qk(i ) is the orientation of j-th link in

k 1

III.

CALIBRATION ALGORITHM

As follows from the previous Section, the input data for

the manipulator calibration are its joint coordinates

Qi (q1i , q2i , ... , qni ) and corresponding end-effector

the i-th experiment. Since this system of equations is

nonlinear with respect to i , it does not have general

analytical solution. Thus, it is reasonable to linearize the

model (1)

positions Pi [ xi yi ]T , i 1, m . The goal is to find

unknown parameters Π {li , i , i 1, n} which ensure

the best mapping of the coordinates Q i to the end-effector

positions Pi that is defined by the geometrical model (1),

which may be re-written in a general form as

where P0i is the end-effector position for the nominal values

of parameters and the joint variables

Pi P0i J i П

T

n

n

P0i lk0 cos k0(i ) lk0 sin k0(i ) , i 1, m ,

k 1

k 1

xi f x Qi , Π ; yi f y Qi , Π ; i 1, m J is the Jacobian matrix, which can be computed by

i

differencing the system (1) with respect to П that leads to

where f x Qi , Π , f y Qi , Π are the right-hand sides

of system (1).

J (i ) J (xli )

J i (xqi )

(i )

To compute Π {li , i , i 1, n} , let us apply the

J yq J yl 22 n

least-square method which minimizes the residuals for all

experimental configurations. Corresponding optimization

where

problem can be written as

т

F

i 1

J (xqi ) l1 sin 1( i )

f Q , Π x f Q , Π y min

2

2

x

i

i

y

i

i

and it can be solved by using stationary condition at the

extreme point F / Πi 0 for i 1, 2n with respect to

Π {li , i , i 1, n} . Corresponding derivations yield

J

(i )

yq

l1 cos 1(i )

... ln sin n( i )

1n

... l j cos

(i )

j

1n

J (xli ) cos 1( i )

... cos n( i )

J (yil) sin 1( i )

... sin n( i )

1n

1n

Taking into account (6), the function (3) can be rewritten as

т

F J i П Pi

i 1

T

Ji П Pi min

where Pi Pi P0i and expressions (4) are reduced to

т

(J

i 1

i

T

J i )·П (J i Pi )

T

1

П (J аT J а ) 1 J аT Pа

Besides, it can be proved that the covariance matrix of the

parameters П [18], defining the identification accuracy,

can be expressed as

i 1

So, the unknown parameters П , can be computed as

E П JTa J а JTa Pа

т

T

where ε a ε1 ε 2 ... ε m .

As follows from (13), the latter expression produces

unbiased estimates

cov(П) (J Ta J а ) 1 J Ta E ε а ·εTa J а (J Ta J а ) 1

where J a J1 J 2 ... J m ; Pa [P1 P2 ... Pm ]T .

To increase the identification accuracy, the foregoing

linearized procedure has to be applied several times, in

accordance with the following iterative algorithm:

Then, taking into account that E ε а ·εTa 2 ·I 2 n , where I 2n

Step 1. Carry out experiments and collect the input data

in the vectors of generalized coordinates Q i and endeffector position Pi ( xi , yi ) . Initialize П 0 .

Step 2. Compute end-effector position via direct

kinematic model (1) using initial generalized coordinates Q i

Step 3. Compute residuals and unknown parameters П

via (11)

Step 4. Correct mathematical model and generalized

coordinates l j l j l j , ji ji j , j 1, m .

Step 5. If required accuracy is not satisfied, repeat from

Step 2.

It should be mentioned, that the proposed iterative

algorithm can produce exact values of {li , i , i 1, n} if

and only if there are no measurement errors in the initial data

{Qi , Pi } . Since in practice it is not true, it is reasonable to

minimize the measurement errors impact via proper selection

of {Qi , Pi } .

T

IV.

1

Pi P0i J i П εi

m

cov(П) 2 J iT J i

i 1

T

m

1

Ji .

i1

For the considered model (1), this sum can be expressed

as

J

m

i1

T

i

A B

Ji

C D

where

A l j lk ·c jk ;

B C l j s jk ;

m

m

i 1

i 1

D c jk ;

c jk cos( j(i ) k(i ) ); s jk sin( j(i ) k(i ) );

where Aj , j m·l j lk ; B j , j C j , j 0; D j , j m, j 1, n , which

can be presented via block matrix

collect all measurement

П JTa J а JTa Pa ε а

T

i

j 1, n; k 1, n

errors. So, expression (11) for computing the vector of the

desired parameters П has to be rewritten as

J

defined by the matrix sum

J

m

i1

where the vector εi xi , yi

Therefore, for the problem of interest, the impact of the

measurement errors (i.e. “quality” of the experiment plan) is

ACCURACY OF CALIBRATION EXPERIMENT

Let us assume that the measurements of x, y are carrying

out with some random errors xi , yi that are assumed to be

iid, with the standard deviation and zero mean value.

Thus, model (6) can be rewritten as

is the identity matrix of the size 2n 2n , the expression (15)

can be simplified to

T

i

L C L L S

Ji

T

C

L S

where L diag (l1 , l2 ,..., ln ) , C c jk , j 1, n; k 1, n ,

S s jk , j 1, n; k 1, n .

This expression allows estimating the identification

accuracy and it can be applied for optimal design of

calibration that is presented in the following Section.

V.

DESIGN OF CALIBRATION EXPERIMENTS

To optimize location of experimental points in the

Cartesian

space

(and

corresponding

manipulator

configurations), let us investigate in details all components

J

J i that is similar to the “information

m

of the matrix

T

i

which leads to

i1

matrix” in classical design of experiments. As it is known

[17], this matrix can be evaluated by several criteria. The

most common of them are A- and D-optimality criteria, but

here it is not reasonable to use the A- criterion because the

J

m

trace of the matrix

T

i

0, if b j, b k

0, if b j , b k

s jk

s jk , if b j

;

c jk , if b j

b

b

s jk , if b k

c jk , if b k

c jk

C / b 0;

S / b 0

The latter guarantees maximum of the relevant determinant

and ensures agreement with the D-optimality.

Validity of the proposed approach and its practical

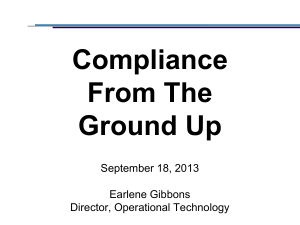

significance was also conformed by a simulation example

that deals with 4-links manipulator with geometrical

parameters l1 260 mm , l2 180 mm , l3 120 mm ,

l4 100 mm and their deviations l1 1.5 mm ,

l2 0.6 mm , l3 0.4 mm , l4 0.7 mm ; and

J i does not depend on the

i1

experiment plan. Besides, the D- criterion is also not

applicable here in its direct form.

Hence, let us introduce a modified D*-optimal criterion

which takes into account the structure of the information

matrix in this particular case. Since this matrix includes

several blocks with different units (linear, angular, etc.), it is

reasonable to focus on optimization of each block separately.

This approach allows to reformulate the problem and to

define the goal as

deviation of zero values of angular coordinates q1 0.5o ,

q2 0.5o , q3 0.7 o , q4 0.3o . All experiments

were carried out for 10 random experimental points, the

results are summarized in the Figure 1. They show that

random plans give rather poor results both for D-optimality

det C max ;

det S min

q j , j 1,m

q j , j 1,m

and D*-optimality criteria comparing to the optimal ones (for

the optimal plans det C 1 and det S 0 ; det D 1 ,

where C c jk / n , S s jk / n correspond to the

where D is normalized block matrix (19)).

diagonal and non-diagonal blocks of (19) respectively. It can

be proved that this goal is satisfied if

det(D)

Optimal plan

1

c jk 0; s jk 0;

j 1, n; k 1, n; j k

0.8

Random plan

0.6

that perfectly corresponds to the classical D-optimality

conditions. For practical convenience, cases of 2-, 3- and 4links manipulators were investigated in details and

corresponding optimality conditions are presented in Table 1.

A correspondence between the proposed approach and

the D-optimality can be also proved analytically. In

particular, straightforward computations give

TABLE I.

Manipulator

0.2

0

0

m

i 1

m

m

c

2i

0; s2i 0;

2i

0; s2i 0;

i 1

m

c

i 1

m

c

i 1

23i

i 1

m

0;

i 1

m

s

i 1

23i

0;

20

30

40

50

Experimental points

OPTIMAL PLAN CONDITIONS FOR 2-, 3- AND 4-LINKS MANIPULATORS

c

3-links

manipulator

10

Figure 1. Determinant values of matrix D' for 4-links manipulator

for random calibration plans with 10 experimental points:

Conditions for optimal plan

2-links

manipulator

4-links

manipulator

0.4

2i

m

c

0;

3i

0;

24 i

0;

m

c

i 1

m

c

m

s

0,

2i

i 1

3i

i 1

i 1

0;

m

3i

0; c23i 0;

3i

0;

i 1

m

s

i 1

m

s

i 1

c2i cos q2i ; s2i sin q2i ; i 1, m

m

s

i 1

Notation

24 i

m

c

i 1

0;

0;

4i

m

34 i

0

23i

i 1

m

s

0;

0;

4i

i 1

c

i 1

m

s

m

s

i 1

34 i

c3i cos q3i ; s3i sin q3i ;

c23i cos(q2i q3i ) ; s3i sin(q2i q3i ) ; i 1, m

c4i cos q4i ; s4i sin q4i ;

c24i cos(q2i q3i q4i ) ; s24i sin(q2i q3i q4i ) ;

0

c34i cos(q3i q4i ) ; s34i sin(q3i q4i ) ; i 1, m

For the proposed set of calibration experiments, the

calibration accuracy can be estimated via the covariance

matrix, which in this case is diagonal and may be presented

as

VI.

SIMULATION STUDY

Let us present some simulation results that demonstrate

efficiency of the proposed technique for several case studies

that deal with two-, three- and four-links manipulators and

employ different number of calibration experiments. It is

0

assumed that in all cases the calibration experiments were

2 m·L L

cov(П ) ·

designed in accordance with expressions developed in

I

0

Section 5 ( see Table 1). To obtain meaningful statistics, the

simulation was repeated 10000 times; the deviation of

where L diag (l1 , l2 ,..., ln ) , and identification accuracy can

measurement error was equal to 0.1 mm.

be evaluated as

It was also assumed that the manipulator geometrical

parameters are l1 260 mm , l2 180 mm , l3 120 mm ,

l4 100 mm and their deviations are equal to 1.5 mm, qi

;

Li

;

i 1, n

m li

m

0.6 mm, -0.4 mm and 0.7 mm. respectively, while the

deviation of zero values of angular coordinates 0.5°, -0.5°,

0.7° and -0.3° for the first, second, third and fourth joints

where qi , Li are standard deviations of angular ( qi ) and

respectively. Short summary of the simulation results are

linear ( li ) parameters from the nominal values.

presented in Table 3 and in Figure 2.

The results show that identification errors of the linear

As follows from this study, the identification accuracy of

parameters depend only on the number of experimental

the experimental result and analytical estimations are in good

points, while the angular parameter errors also depend on the

agreement. In particular, for linear parameters, the

link length.

TABLE II.

ESTIMATION OF THE IDENTIFICATION ACCURACY OF GEOMETRICAL PARAMETERS: ANALYTICAL SOLUTION

m

(J

Manipulator

i 1

T

i

Ji )

Identification accuracy

2-links

manipulator

diag (m l12 , m l2 2 , m, m) ,

3-links

manipulator

diag (m l12 , m l2 2 , m l32 , m, m, m)

4-links

manipulator

diag (m l , m l2 , m l3 , m l4 , m, m, m, m)

q1

m l1

2

TABLE III.

2

m l1

; q2

q1

2

1

q1

2

L1

m l1

m

;

; q2

m l2

m l2

; q3

; q2

L2

m l2

m

; L1

m l3

L3

;

m

; L1

; q3

;

m

m l3

m

L2

m

; L2

m

; L3

; q4

;

m l4

L4

m

;

m

ESTIMATION OF IDENTIFICATION ACCURACY OF GEOMETRICAL PARAMETERS

Identification accuracy

Manipulator

2-links

manipulator

3-links

manipulator

4-links

manipulator

Model parameters

L1 260 mm, L1 1.5 mm,

q1 0.5 deg

L2 180 mm, L2 0.6 mm, q2 0.5 deg

L1 260 mm, L1 1.5 mm,

,

q1 0.5 deg

3 experimental points

20 experimental points

L1 0.058 mm, q1 0.013deg

L1 0.058 mm, q1 0.005deg

L2 0.058 mm, q2 0.018deg

L2 0.058 mm, q2 0.007 deg

L1 0.058 mm, q1 0.013deg

L1 0.022 mm, q1 0.005deg

L2 180 mm, L2 0.6 mm, q2 0.5 deg

L2 0.058 mm, q2 0.018deg

L2 0.022 mm, q2 0.007 deg

L3 120 mm, L3 0.4 mm, q3 0.7 deg

L3 0.058 mm

L3 0.022 mm

L1 260 mm, L1 1.5 mm,

q1 0.5 deg

q3 0.027 deg

q3 0.011deg

L1 0.058 mm, q1 0.013deg

L1 0.022 mm, q1 0.005deg

L2 180 mm, L2 0.6 mm, q2 0.5 deg

L2 0.058 mm, q2 0.018deg

L2 0.022 mm, q2 0.007 deg

L3 120 mm, L3 0.4 mm, q3 0.7 deg

L3 0.058 mm

q3 0.027 deg

L3 0.022 mm

q3 0.011deg

L4 100 mm, L4 0.7 mm,

L4 0.058 mm

q4 0.033deg

L4 0.022 mm

q4 0.013deg

q4 0.3 deg

0.1

H (l1 ), mm

H (l2 ), mm

0.1

0.1

l1

0.08

l2

0.08

2

0.04

0.06

0.06

0.04

0.04

1

0.02

5

15

20

m

10

15

20

m

q2

0.025

0.015

0.02

2

0.02

5

1

10

15

20

m

20

m

2

0.06

q3

10

10

15

20

m

20

m

H (q4 ),deg

q4

0.05

0.03

2

15

20

m

0.01

5

2

0.03

0.02

0.005

5

0.02

5

0.04

1

10

15

0.04

0.01

1

2

0.04

0.015

0.01

0.06

0.05

0.03

q1

l4

0.08

H (q3 ),deg

H (q2 ),deg

0.02

H (l4 ), mm

1

0.02

5

H (q1 ),deg

0.005

5

l3

2

1

10

0.1

0.08

2

0.06

H (l3 ), mm

0.02

1

1

10

15

20

m

0.01

5

10

15

Figure 2. Identification accuracy for the geometrical parameters identification of 4-links manipulator with optimal experiment planning:

"x" are experimental values corresponding to the optimal calibration plan, "o" are experimental values corresponding to the standard calibration plan

"1" is analytical curve coresponding to the optimal plan, "2" is an average experemental curve corresponding to 10000 random calibtration plans.

identification error reduces from 0.022 mm to 0.005 mm

while the experiment number increases from 4 to 20.

Besides, these results allow defining minimum number of

experimental points to satisfy the required accuracy. Thus, to

satisfy an accuracy of 0.001 mm for linear parameters it is

required to carry out 100 experiments, which will provide

accuracy for angular parameters 0.002°, 0.003°, 0.005° and

0.006° respectively.

VII. CONCLUSION

The paper presents a new approach for design of

calibration experiments that allows essentially reducing the

identification errors due to proper selection of the

manipulator postures employed in the measurements. There

were obtained analytical expressions describing set of the

optimal postures corresponding the proposed D*-criterion

that is adopted to special structure of the information matrix.

Validity of the obtained results and their practical

significance were confirmed via simulation study that deals

with two-, three- and four-links planar manipulators.

Compared to previous contributions, these results can be

treated as further development of the design-of-experiments

theory that is adapted to the specific type of the non-linear

models that arise in robot kinematics. Future work will focus

on extension of these results for non-planar manipulators.

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

ACKNOWLEDGEMENTS

The work presented in this paper was partially funded by

the Region “Pays de la Loire”, France and by the project

ANR COROUSSO, France.

REFERENCES

[1]

[2]

Z.Roth, B.Mooring and B.Ravani, “An overview of robot

calibration,” IEEE Journal of Robotic and Automation, Vol. 3, No 5, ,

1987, pp. 377-385.

A.Y. Elatta, Li Pei Gen, Fan Liang Zhi, Yu Daoyuan and Luo Fei,

“An Overview of Robot Calibration,” Information Technology

Journal Vol 3, No 1, 2004, pp. 74-78.

[15]

[16]

[17]

[18]

B. W, Mooring, Z, S, Roth and M. R. Driels, “Fundamentals of

Manipulator Calibration,” Jone Wiley& Sons, 1991.

J. M. Hollerbach, “A Survey of Kinematic Calibration,” The Roborics

Review 1, Cambridge, MIT Press, 1989, pp. 207-242.

S. Hayati, “Robot Arm Geometric Link Parameter Estimation,” Proc

22 IEEE. Conference on Desaining and Cantrol, San Antonio, pp.

1477-1483, 1983.

H. W. Stone, Kinematic Modeling, Identification, and Central of

Robor Forward Manipulators, Boston,Kluwer,1987.

H. Zhuang, Z.S. Roth and F. Harnano, “A complete and

pararnetricatly continuous kinematic model for robot manipulators,”

IEEE Trans. Robotics and Automation,Vol. 8, 1992, pp.451-463.

M. Ikits; and J.M. Hollerbach, “Kinematic calibration using a plane

constraint,” Robotics and Automation, 1997. Proceedings., 1997

IEEE International Conference on Vol 4, Apr 1997, pp 3191 - 3196

C.R. Mirman, and K.C. Gupta, “Compensation of robot joint

variables using special Jacobian Matrices,”. J. Robotic System, Vol.

9, 1992, pp. 133-137.

B. Mooring, W., M. Driels and Z. Roth, Fundamentals of Manipulator

Calibration. 1991: John Wiley & Sons, NY, 1991.

Y. Sun and J.M. Hollerbach, "Observability index selection for robot

calibration," IEEE International Conference on Robotics and

Automation, 2008 (ICRA 2008), pp 831-836.

Y. Sun and J.M. Hollerbach, "Active robot calibration algorithm,"

IEEE International Conference on Robotics and Automation, 2008

(ICRA 2008), pp. 1276-1281.

J.M. Hollerbach, W Khalil and M Gautier, ''Model Identification," In:

Springer handbook of robotics, 2008, Part B, pp 321-344

H. Zhuang; J. Wu and W. Huang, "Optimal planning of robot

calibration experiments by genetic algorithms," IEEE International

Conference on Robotics and Automation, 1996 (ICRA 1996), pp.

981-986

D. Daney, Y. Papegay and B. Madeline, " Choosing Measurement

Poses for Robot Calibration with the Local Convergence Method and

Tabu Search," International Jornal of Robotics Research, Vol 24(6),

Juin 2005, pp. 501-518

J. Borm and C. Menq, "Determination of optimal measurement

configurations for robot calibration based on observibility measure,"

Int. Journal of Robotics Research, Vol 10(1), 1991, pp. 51–63.

A.C. Atkinson and A.N. Donev, Optimum Experiment Designs.

Oxford University Press, Oxford, 1992.

D.R. Cox, Planning of experiments, Wiley, New York, 1958.