- Mount Sinai Hospital

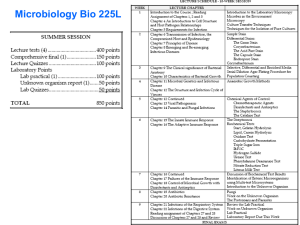

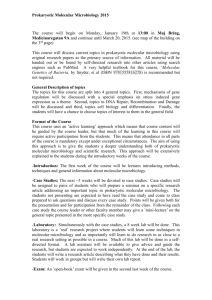

advertisement