Wayne County Public Schools

advertisement

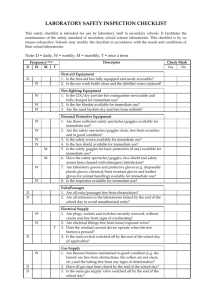

Wayne County Public Schools Chemical Hygiene Plan for School Science Laboratories Introduction Public and private schools over the past few years have had to comply with various Hazard Communication or “Right to Know” laws. These laws were written for industrial production facilities, and did not address the specific safety concerns found in a laboratory setting. (For the purpose of this document, a “laboratory” is any area where teachers or students are using chemicals for educational purposes.) In 1990, the Occupational Safety and Health Administration (OSHA) instituted “The Laboratory Standard”— Occupational Exposure to Hazardous Chemicals in Laboratories (29 CFR 1910.1450). This Federal “Laboratory Standard” has been designed to address the specific safety needs of the laboratory. The OSHA Laboratory Standard ensures that employees who work in a laboratory setting will be protected from any chemical exposure that exceeds permissible exposure limits (PELs) and that employees are educated as to the hazardous nature of the chemicals they use in the laboratory. To achieve this goal the Laboratory Standard requires the school district to appoint a chemical hygiene officer to develop, implement, and monitor a chemical hygiene plan. The Chemical Hygiene Officer will work with the Middle and High School Science Safety Teams to develop, update, implement, and enforce a Chemical Hygiene Plan. 1 The Chemical Hygiene Officer (CHO), Safety Consultant, and School Science Safety Teams for 2015-2016 are: Chemical Hygiene Officer: Safety Consultant: Andy Forsleff, Science Lead Teacher Allen Smith, Maintenance Department Safety Coordinator High School Science Safety Team: School Charles B. Aycock High Charles B. Aycock High Eastern Wayne High Eastern Wayne High Goldsboro High Goldsboro High Rosewood High Southern Wayne High Southern Wayne High Spring Creek High Spring Creek High Wayne Academy Wayne School of Engineering Wayne School of Engineering Wayne Early/Middle College High Name Rachel (Beth) Hagwood Brian Rada Patricia Malcolm Tracey Grady Patricia Velasco Michael Barnett Heather Turner Andy Norris Gerald Reedy Joseph Beamon Svetlana Beamon Craig Uzzell Susan Randolph Sula Teachey Sheila Covar Position Science Chair CHO Science Chair CHO Science Chair CHO Science Chair/CHO Science Chair CHO Science Chair CHO Science Chair/CHO Science Chair CHO Science Chair Middle School Science Safety Team: School Brogden Middle Dillard Middle Dillard Middle Dillard Middle Eastern Wayne Middle Eastern Wayne Middle Grantham Middle Grantham Middle Grantham Middle Greenwood Middle Mount Olive Middle Mount Olive Middle Norwayne Middle Norwayne Middle Rosewood Middle Rosewood Middle Spring Creek Middle Name Lynette Wilson Aaron Fazakerly Kim Stedner Dennis Stringfield Donald Rouse Donna Lee Jennifer Williams Elizabeth McDaniel Amy Kelly Lori Batten Mary Jo Lambert Nana Strickland Amy Stamper Robin Gales Hill Pam Casey Kacy Smith Julie Slye Position Science Chair/CHO Science Chair 5th-6th Science Chair 7th-8th CHO Science Chair CHO Science Chair CHO 7th-8th CHO 5th-6th Science Chair/CHO Science Chair CHO Science Chair CHO Science Chair CHO Science Chair/CHO 2 The Chemical Hygiene Plan—An Overview The Chemical Hygiene Plan is the major ingredient of the OSHA Laboratory Standard. It details how each employee will be protected from overexposure to hazardous chemicals and it describes specific work practices in the laboratory to minimize employee risk. The Chemical Hygiene Plan should: 1) Protect employees from health hazards associated with hazardous chemicals in the laboratory. 2) Keep chemical exposures below established permissible exposure limits. The Chemical Hygiene Plan must be readily available to employees. Although non-employee students are not covered by the OSHA regulation, each student and the student’s guardian should attest by signature that they have read and understand the safety rules in a science laboratory. The school district’s duty to review and evaluate the effectiveness of the Chemical Hygiene Plan at least annually and update it as necessary shall fall upon the Chemical Hygiene Officer and the Safety Consultant. The Chemical Hygiene Plan should include each of the following elements and should include specific measures the employer will take to ensure laboratory employee protection. I. Standard Operating Guidelines A) B) C) D) E) F) G) General Employee Rules and Guidelines General Laboratory Rules and Guidelines Personal Hygiene Guidelines Protective Clothing Requirements Housekeeping Rules Spill and Accident Procedures Chemical Storage Rules and Procedures 1) Compressed Gas Handling Instructions – LP Gas 2) Flammable Chemical Storage 3) Corrosive Materials Handling Instructions and Storage 4) Disposal of Chemicals H) Procedure—Specific Safety Rules and Guidelines I) Safety Equipment Inspection II. Employee Training III. Exposure Evaluations IV. Medical Evaluations V. Emergency Evacuation Plan VI. Sign-Off Sheet School Level Chemical Hygiene Plans 3 Each middle and high school science department will develop a school level Chemical Hygiene Plan. The Plan should reflect the elements set forth in the Wayne County Public Schools Chemical Hygiene Plan. The School Plan may contain additional safety guidelines to ensure the safety and welfare of students and staff. It is the expectation that students, as well as employees, comply with all practices and procedures in the school’s Plan. By October 15th of each school year, an updated copy of the Plan shall be filed with Wayne County Public Schools Chemical Hygiene Officer. Wayne County Public Schools Chemical Hygiene Plan for School Science Laboratories I. Standard Operating Guidelines A. General Employee Rules and Guidelines 1) 2) 3) 4) Minimize all chemical exposures. Avoid skin contact with chemicals. Avoid underestimation of chemical hazards and risks. Develop a firm goggle policy. Wear appropriate eye protection at all times. Protective goggles (with ANSI Z87 impact rating) must be worn any time there is the potential for flying objects or debris, also whenever glassware or heat are used in the laboratory. Chemical splash goggles must be worn any time liquids are used. 5) Always notify another person when working in the laboratory, chemical storage room, or prep areas. 6) Flammable liquids require special attention. Never use these materials near any source of ignition, spark, or open flame. 7) Never perform a first-time chemical demonstration in front of your class. Always perform first-time demonstrations in front of other instructors to evaluate the safety of the demonstration. 8) Never store chemicals over, under, or near a sink. 9) Only authorized personnel should be allowed in the chemical storage room. 10) Have a fire blanket easily accessible in case of an accident. Fire blankets are NOT to be used to extinguish flames on people. 11) All science teachers should be knowledgeable on how to use all safety devices in the laboratory (e.g., eyewash fountains, safety showers, fire extinguisher, etc.) in order to use them quickly in an emergency. 12) Know appropriate procedures in the event of a power failure. 13) Have a plan in place for notifying appropriate personnel for utility control (gas, electrical, and water). 14) Do not taste chemicals. 15) Use a safety shield whenever an explosion or implosion might occur. 16) Read all chemical labels prior to use. 17) Know and understand the hazards of the chemical as stated in the Safety Data Sheets (SDS) and other references. 18) Use protective safety equipment to reduce potential exposure, i.e. gloves, fume hood, ventilation fans, etc. 19) Know the locations for all personal safety and emergency equipment, eye wash fountains, safety shower, fire extinguisher, and spill control materials. 4 20) Know how to properly store all chemicals in their compatible chemical families. (Consult publications such as the Flinn Chemical Catalog/Reference Manual for details.) 21) Know proper transportation and disposal procedures for chemicals. 22) Know appropriate emergency procedures, waste disposal, spill clean up, evacuation routes and fire emergency notification. 23) Know and understand the personal hygiene practices outlined in the Chemical Hygiene Plan. General Laboratory Rules and Guidelines 23) Create a written first aid policy; whether it says to treat or to seek further medical assistance. Your first aid policy must be written down. 24) The laboratory should be well ventilated. a. A ventilation fan should remove the air a minimum of 8 air changes per hour. Air for laboratory ventilation should directly flow into the laboratory from non-laboratory areas and out to the exterior of the building. b. Ventilation for a fume hood (velocity) must be checked with a velometer by the science/chemistry teacher a minimum of every 3 months to ensure uniformity of air flow over the face of the hood and to detect any changes. The operational level should be 70-100 linear feet per minute as measured by the velometer. c. Storage rooms should be ventilated by at least four changes of air per hour. Isolate the chemical storage exhaust from the general building ventilation system. 25) Post emergency telephone numbers in the chemical storage room. Have some means of emergency communication in the laboratory, chemical storage room and prep area. 26) In the event of an accident that requires the assistance of outside personnel, as soon as time allows, fill out an accident report describing the event in detail. The accident report must be developed by the science/chemistry teacher and forwarded to the principal who will send a copy to the Chemical Hygiene Officer. The Chemical Hygiene Officer must have already been notified of the accident. 27) All laboratories should have an eyewash fountain capable of treating both eyes continuously for 15 minutes with copious quantities of tempered aerated potable water. Teach everyone how to use the eyewash fountain quickly in case of an emergency. Eyewash effectiveness and operation should be inspected before every lab. Eyewash fountains shall be activated weekly and this is to be documented. Promptly repair any eyewash that does not provide adequate water flow. A repair order must be generated by the science/chemistry teacher and forwarded to the principal who will notify the maintenance department. 28) Each laboratory area should be equipped with a safety shower or body drench. The ANSI standard Z358.1-1990 requires that emergency showers be located no more than 10 seconds in time or greater than 100 feet in distance from the hazard. Water flow must be sufficient to drench the subject rapidly. ANSI Z358.1-1990 requires a minimum flow of 20 gallons per minute of potable water. When possible, tempered water should be used in safety showers. Safety showers shall be activated weekly and this is to be documented. Promptly repair any shower or body drench that does not meet the water flow requirements of ANSI Z358.1. A repair order must by 5 generated by the science/chemistry teacher and forwarded to the principal who will notify the operations department. 29) Have appropriate types and sizes of fire extinguishers. Triclass ABC fire extinguishers are appropriate for laboratories. Fire extinguishers should be inspected by the operations department at least every three months. 30) An approved eyewash station and fire blanket should be accessible within 10 seconds from any point in the laboratory. 31) All chemical containers must have labels. Read all labels carefully—the names of many chemicals look alike at first glance. 32) Safety Data Sheet (SDS) must be available for every hazardous chemical used in the laboratory. 33) Be thoroughly familiar with the hazards and precautions for protection before using any chemical. Study the precautionary label and review its contents before using any chemical substance 34) Dispose of all chemicals properly. All disposal procedures used should conform to state and local regulations. Schools should use the Wayne County Public Schools Chemical Disposal Form to initiate any disposal of hazardous chemicals. 35) Neutralizing chemicals, such as a spill kit, dry sand, kitty litter, and other spill control materials should be readily available. 36) Do not use chipped, etched or cracked glassware. Glassware which is chipped or scratched presents a serious breakage hazard when heated or handled. 37) Do not drink from lab glassware or other lab vessels. 38) No food in the laboratory. Do not eat, drink, or chew gum in the laboratory. 39) Do not apply cosmetics in areas where laboratory chemicals are present. 40) Never pipet by mouth. 41) Contact lens wearers should be provided with non-vented or indirect-vented chemical splash goggles in the laboratory. 42) Do not block fire exits. 43) Have an alternative evacuation route in the event your primary route becomes blocked. A copy of the school’s Emergency Evacuation Plan should be attached to each school’s Chemical Hygiene Plan. 44) Practice your emergency plans. 45) Keep all aisles clear. 46) Do not run in the laboratory. 47) Access to exits, emergency equipment, and master utility controls should never be blocked. 48) Do not operate electrical equipment with wet hands. 49) All accidents or near accidents (close calls) should be carefully analyzed with the results distributed to all who might benefit. 50) Never perform unauthorized laboratory experiments. 51) It is recommended that only science classes be held in science laboratories. It is important that any teacher instructing in a lab setting be aware of the school’s Chemical Hygiene Plan and be responsible for its implementation. 6 B. Personal Hygiene Guidelines 1) 2) 3) 4) 5) D. Do not apply cosmetics or smoke, eat, chew, or drink in the laboratory. Do not pipet by mouth; always use a pipet bulb or other appropriate suction device. Wash hands thoroughly after any chemical exposure and before leaving the laboratory. Never smell chemicals directly; odors should be wafted only with teacher consent. Never bring foodstuffs, opened or closed into the lab, chemical prep, or storage room. Foodstuffs should not be eaten if in a room with toxic materials. Protective Clothing Requirements 1) Eye protection must be worn. Chemical splash goggles must meet ANSI Z87.1 Standard. Wear face shields in addition to goggles when dealing with corrosive liquids, (i.e., full strength acids and bases). 2) Wear gloves that offer protection for all hazards you may find in the lab. Test for holes every time you wear your gloves. Nitrile gloves are strongly preferred over latex gloves due to potential allergies. 3) Always wear a full-length lab coat or a chemical-resistant apron. 4) Wear low-heeled shoes. Do not wear open-toed shoes or sandals of any kind. Always wear socks in the laboratory. 5) Do not wear shorts--wear long pants. 6) Do not wear loose or balloon sleeves. 7) Tie back long hair. 8) Contact lens wearers should be provided with non-vented or indirect-vented chemical splash goggles in the laboratory. 9) Do not wear hanging jewelry. 10) Do not wear a long or loose necktie. 11) Do not wear an absorbent watch strap 12) Inspect all protective safety equipment before use. If defective, do not use. E. Housekeeping Rules 1) Keep chemicals in the chemical prep and storage room. If chemicals are moved to the classroom for lab, they must be returned to their proper storage location at the end of the day’s laboratory periods. Students are not allowed to transport chemicals between classrooms. 2) Waste materials require proper containers and labels. 3) Do not store items in the fume hood. The storage of items in the fume hood is a fire hazard and decreases the efficiency of the fume hood. 4) Label all chemicals with names and hazards. Prepared solutions should be labeled with date, concentrations, and initials of preparer. 5) Never block access to exits or emergency equipment. 6) Clean up all spills properly and promptly. 7) Work and floor surfaces should be cleaned regularly and kept free of clutter. 7 F. Spill and Accident Procedures 1) Notify—Call for help. Evacuate—Get everyone to a safe location. Assemble—Organize the students and all workers. Report—Fill out a detailed accident report after the emergency is over. 2) Clean up spills immediately and thoroughly. Follow approved spill cleanup procedures; spills should only be cleaned up by approved personnel. 3) A bucket of dry sand should be available as a Class D fire extinguisher and to aid in providing traction on a slippery floor. 4) Neutralizer for both acid and base spills should be available in the event of a chemical spill. G. Chemical Storage Rules and Procedures 1) A Safety Data Sheet (SDS) must be available for every hazardous chemical in the science laboratory. The chemistry teacher/science chair should put the SDSs in notebooks labeled Current Science Chemicals and should store the notebooks in the front office and science classrooms. The notebooks must be current at all times. 2) The chemistry/science teacher must keep an updated inventory of all chemicals, their amounts and location. Stored chemicals should be examined annually for replacement, deterioration and chemical integrity. Your entire Chemical Hygiene Plan is based on the proper updated inventory always being available. The science chair should keep a copy of each science teacher’s updated chemical inventory. No hazardous chemical will be used or stored without a SDS on file. 3) Science teachers should label all chemical solutions made with the identity of the contents, date, concentration, hazard information, and the initials of the preparer. 4) Date label all chemicals with the purchase date. This will allow anyone to determine the age of a substance at a later date. 5) Establish a separate and secure storage room for chemicals. 6) Do not allow incoming shipments of chemicals to be opened or transported by school personnel other than qualified science teachers. The special shipping containers can prove valuable for chemical storage. 7) All chemicals should be stored in chemically compatible families (See SDSs or publications such as the Flinn Chemical Catalog/Reference Manual for details). 8) Store the minimum amount of chemicals needed. 9) Store corrosives in appropriate corrosives cabinets. 10) Flammable materials should be stored in an approved flammable storage cabinet. 11) Do not store chemicals under a fume hood. 12) If possible, keep certain items in the original shipping package, e.g., acids and bases in the special Styrofoam cubes. 13) Avoid storing chemicals on shelves above eye level. 14) The entry to the chemical laboratory should be posted with the National Fire Protection Association diamond, which provides emergency information to fire fighters. 15) Shelving above any work area, such as a sink, should be free of chemicals or other loose miscellany. 16) Chemical storage cabinets should be secured to walls or floor to prevent tipping of entire sections. 17) Shelves used to store chemicals should be equipped with lips. 18) Chemicals should not be stored on the floor except in approved shipping containers. 8 19) Storage rooms should be ventilated by at least four changes of air per hour. Isolate the chemical storage exhaust from the general building ventilation system. 20) Never store food in a laboratory refrigerator. 21) Store chemicals in a separate, locked, dedicated storage area. 22) Only authorized personnel are allowed in the chemical storage room. 23) Chemical exposure to heat or direct sunlight should be avoided. 24) All science classrooms should be locked when left unattended. 1. Handling Instructions for LP Gas 1) Compressed gases should be handled as high-energy sources, and therefore, as potential explosives. 2) Never lubricate, modify, force or tamper with a gas valve. 3) The master valve for gas should be in the off position when gas is not required for the lab activity. 2. Storage Requirements—Flammable Chemicals 1) 2) 3) 4) 5) Store all flammables in a dedicated flammables cabinet. Store away from all sources of ignition. Store away from all oxidizers. Never store flammables in a refrigerator. Avoid storing any chemicals, especially flammable materials, in direct sunlight. 3. Storage Requirements—Corrosive Materials Handling Instructions 1) Store corrosives in appropriate corrosives cabinets. 2) Working with corrosive materials requires special eyewear. Wear a chemical splash face shield in addition to goggles when handling corrosive materials. 3) Inspect all shelf clips in your acid cabinet at least every three months to check for possible corrosion. These shelf clips are the only thing between you and a collapsed shelf. They require special attention. 4. Disposal of Chemicals Schools should use the Wayne County Public Schools Chemical Disposal Inventory Form to initiate the disposal process. A copy of the inventory form must by kept with the chemicals to be removed and a copy must be sent to the Chemical Hygiene Officer. It is the school’s responsibility to maintain a Chemical Disposal Inventory at least annually. 9 H. Procedure--Specific Safety Rules and Guidelines (for hazardous chemicals) 1) Use a fume hood when the permissible exposure limit for a chemical is less than 50 ppm as indicated on the chemical SDS. 2) Use allergens only under a fume hood. 3) Handle toxic, corrosive, flammable and noxious chemicals under a fume hood. 4) Do not expose flammable liquids to open flame, sparks, heat or any source of ignition. 5) Use of flammable solids (sodium, potassium, lithium, etc.) is prohibited. 6) Use extreme caution when handling finely divided (dust-like) material. Finely divided materials may form explosive mixtures with air. 7) Use of mercury for any educational purpose is prohibited. I. Safety Equipment Inspection There are many safety items necessary for compliance to the OSHA Laboratory Standard. They include, but are not limited to: 1) 2) 3) 4) 5) 6) Goggles Ventilation Fans Fume Hoods Fire Extinguishers Eyewash Fountains Safety Showers The Laboratory Standard clearly states that if you have a piece of safety equipment, it must be functional at all times. This statement applies to all safety equipment, regardless of whether it is required or only recommended in the standard. 1) Goggles must be clean and functional. The science/chemistry teacher is responsible for cleaning and inspecting goggles and disposing of those that are not functional. 2) Laboratory ventilation must meet the standard of eight air changes per hour and ventilation fans must be tested quarterly by the maintenance department. 3) Fume hoods must be operational at the level of 70-100 linear feet per minute as measured by a velometer. The science/chemistry teacher is responsible for maintaining this measurement process every three months. This must be documented. 4) Fire extinguishers must be of the right type, Tri-class ABC, and they must always be properly inspected by the operations department every three months. 5) Eyewash fountains must be functional and flushed at weekly. This must be documented. 6) Safety showers must be functional and activated at weekly. This must be documented. Any safety equipment failing inspection or reported to be out of order at any time must be repaired immediately. Any repair order must be generated by the science/chemistry teacher and forwarded to the principal who will notify the maintenance department. 10 II. Employee Training System-wide Science Safety training sessions will be provided annually for middle and high school science teachers. The training will be coordinated by the Safety Consultant and/or the Science Lead Teacher. The training may include: 1) 2) 3) 4) III. Content and location of the Chemical Hygiene Plan and The Laboratory Standard. The proper use and location of all safety equipment. Reading, understanding, and locating chemical Safety Data Sheets (SDS). Safety updates on new equipment and materials will be provided as soon as possible after a new hazard is identified. Exposure Evaluations In the event of an overexposure, after the immediate event, the chemistry/science teacher must document all chemicals and circumstances involved in the overexposure. This information can be used to change safety practices to further improve lab safety. It is necessary to maintain these files and make them accessible to employees. Signs of overexposure are numerous; they may include: 1) 2) 3) 4) Accidental breakage of a hazardous material container. A skin rash or irritation occurring because of contact with a chemical. Caustic splash to eyes, face, or body. Symptoms such as nausea, dizziness and others. IV. Medical Evaluations Medical consultation and examination will be available to employees when: a) Any sign or symptom of an overexposure to a chemical is present. b) There has been a spill or uncontrolled release of chemical fumes. The medical examinations dealing with the overexposure must be documented and other employees working under the same conditions must be notified. All documentation must be kept on file and accessible by other employees working in this area. V. Emergency Evacuation Plan Emergency evacuation procedures have been established at each school according to its Safe School Plan, which is mandated by state law. In the event evacuation is necessary, the science/chemistry teacher should notify the administration at the school. The evacuation procedures set forth in the school’s Safe School Plan will serve as the Emergency Evacuation Plan for the school’s Chemical Hygiene Plan. It is recommended that each school attach a copy of its Emergency Evacuation Plan to its Chemical Hygiene Plan. 11 VI. Sign-Off Sheet for the Chemical Hygiene Plan Each member’s signature acknowledges that he/she has read and understands the county’s Chemical Hygiene Plan. _______________________________________ ____________ Andy Forsleff date _______________________________________ ____________ Rachel (Beth) Hagwood date _______________________________________ ____________ Brian Rada date _______________________________________ ____________ Amy Strickland-Rouse date _______________________________________ ____________ Patricia Velasco date _______________________________________ ____________ Heather Turner date _______________________________________ ____________ Andy Norris date _______________________________________ ____________ Gerald Reedy date _______________________________________ ____________ Joseph Beamon date _______________________________________ ____________ Svetlana Beamon date _______________________________________ ____________ date _______________________________________ ____________ Susan Randolph date _______________________________________ ____________ Sula Teachey date _______________________________________ ____________ Sheila Covar date _______________________________________ ____________ Allen Smith date 12