Unit 5

advertisement

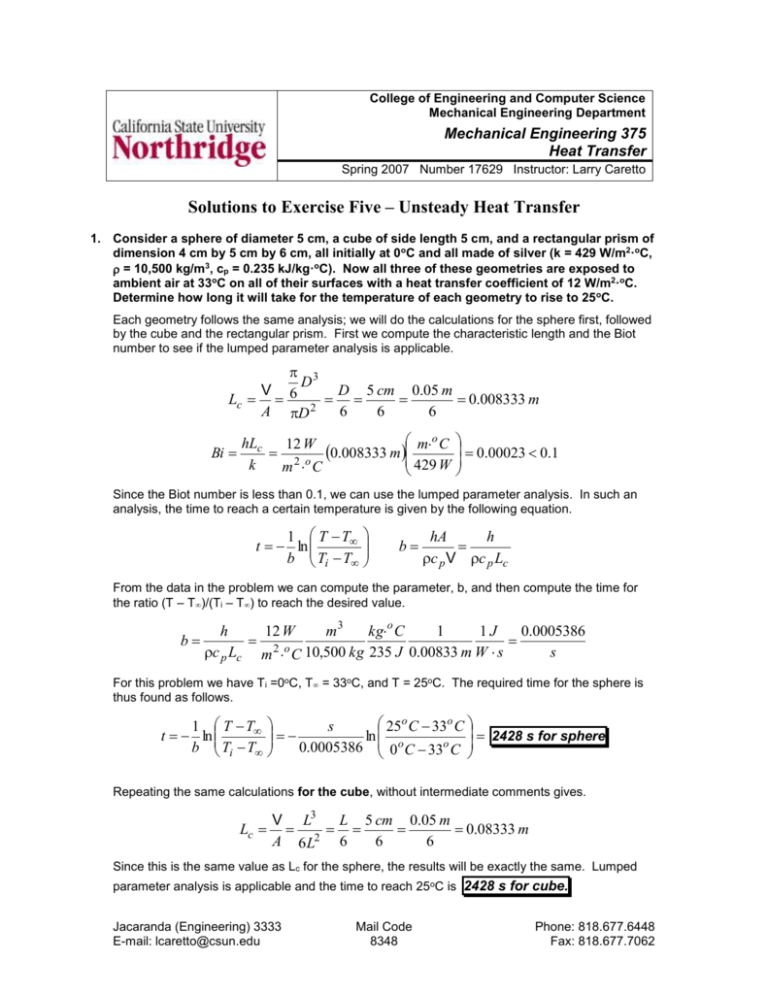

College of Engineering and Computer Science Mechanical Engineering Department Mechanical Engineering 375 Heat Transfer Spring 2007 Number 17629 Instructor: Larry Caretto Solutions to Exercise Five – Unsteady Heat Transfer 1. Consider a sphere of diameter 5 cm, a cube of side length 5 cm, and a rectangular prism of dimension 4 cm by 5 cm by 6 cm, all initially at 0oC and all made of silver (k = 429 W/m2·oC, = 10,500 kg/m3, cp = 0.235 kJ/kg·oC). Now all three of these geometries are exposed to ambient air at 33oC on all of their surfaces with a heat transfer coefficient of 12 W/m2·oC. Determine how long it will take for the temperature of each geometry to rise to 25 oC. Each geometry follows the same analysis; we will do the calculations for the sphere first, followed by the cube and the rectangular prism. First we compute the characteristic length and the Biot number to see if the lumped parameter analysis is applicable. 3 D V 6 D 5 cm 0.05 m Lc 0.008333 m A D 2 6 6 6 mo C hLc 12 W 2 o 0.008333 m 429 W k m C Bi 0.00023 0.1 Since the Biot number is less than 0.1, we can use the lumped parameter analysis. In such an analysis, the time to reach a certain temperature is given by the following equation. 1 T T t ln b Ti T b hA h c p V c p Lc From the data in the problem we can compute the parameter, b, and then compute the time for the ratio (T – T)/(Ti – T) to reach the desired value. b h c p Lc m3 kgo C 1 1J 0.0005386 s m 2 o C 10,500 kg 235 J 0.00833 m W s 12 W For this problem we have Ti =0oC, T = 33oC, and T = 25oC. The required time for the sphere is thus found as follows. 25o C 33o C 1 T T s 2428 s for sphere t ln ln o b Ti T 0.0005386 0 C 33o C Repeating the same calculations for the cube, without intermediate comments gives. Lc V L3 L 5 cm 0.05 m 2 0.08333 m A 6L 6 6 6 Since this is the same value as Lc for the sphere, the results will be exactly the same. Lumped parameter analysis is applicable and the time to reach 25oC is 2428 s for cube. Jacaranda (Engineering) 3333 E-mail: lcaretto@csun.edu Mail Code 8348 Phone: 818.677.6448 Fax: 818.677.7062 Exercise five solutions ME 375, L. S. Caretto, Spring 2007 Page 2 Finally, repeating the calculations for the rectangular prism gives Lc L1L2 L3 4 cm5 cm6 cm V 0.8108 cm 0.008108 m A 2L1L2 L2 L3 L1L3 24 cm5 cm 5 cm6 cm 4 cm6 cm Bi mo C hLc 12 W 2 o 0.008108 m 429 W k m C 0.00023 0.1 Since the Biot number is less than 0.1, we can use the lumped parameter analysis. m3 kgo C 1 1J 0.0005998 b 2o c p Lc m C 10,500 kg 235 J 0.008108 m W s s h 12 W For this problem we have Ti =0oC, T = 33oC, and T = 25oC. The required time for the sphere is thus found as follows. 1 T T t ln b Ti T 25o C 33o C s ln o 0 C 33o C 2363 s for prism. 0 . 0005998 2. Cylindrical brass pellets (k = 64.1 Btu/h ft·oF, = 532 lbm/ft3, and cp = 0.092 Btu/lbm·oF) that are 2-in in diameter and 1 in long initially at 250oF are quenched in a water bath at 120oF for a period of 2 minutes. If the convection heat transfer coefficient is 42 Btu/h ft2·oF, determine the temperature of the balls after quenching First we compute the characteristic length and the Biot number to see if the lumped parameter analysis is applicable. V Lc A LD 2 1 1 ft 4 0.25 in 0.02083 ft 2 2 4 2 4 12 in D 2 DL L D 1 in 2 in 4 h fto F hLc 42 Btu 0.014 0.1 0.02083 ft Bi k 64 . 1 Btu h ft 2 o F Since the Biot number is less than 0.1, we can use the lumped parameter analysis. The temperature after a time, t, is given by the following equation. T T Ti T e bt b hA h c p V c p Lc From the data in the problem we can compute the parameter, b, and then compute the temperature after 2 minutes. b h c p Lc lbm o F ft 3 1 41.18 1 h 0.6865 h 60 min 60 min h ft 2 o F 532 lbm 0.092 Btu 0.02083 ft 42 Btu From the problem data we have T = 120oF and Ti = 250oF. The temperature after a quenching time of 2 minutes is found as follows. Exercise five solutions ME 375, L. S. Caretto, Spring 2007 T T Ti T e bt 120 F 250 F 120 F e o o o 0.6865 2 min min = Page 3 153oF 3. A 35-cm diameter cylindrical shaft made of stainless steel 304 (k = 14.9 W/m·oC, = 7900 kg/m3, cp = 477 kJ/kg·oC) comes out of an oven at a uniform temperature of 400oC. The shaft is then allowed to cool slowly in a chamber at 150oC with an average heat transfer coefficient of 60 W/m2·oC. Determine the temperature center of the shaft 20 min after the start of the cooling process. (Problem 4-41 in text.) We can use the equation below from the class notes to compute the characteristic length of the cylinder. Since we do not have any data for the length of the “long” cylinder we will assume that is the ratio D/L << 2 and can be neglected in computing the characteristic length. V Lc A 2 D L 4 D D 35 cm 4 8.75 cm 0.0875 m 2 2 4 D 4 4 2 D DL 1 4 L D 2L Bi 1 mo C hLc 60 W 2 o 0.0875 m 14.9 W k m C The Biot number is greater than 0.1 so we have to use the analysis with charts. The chart for long cylinders is Figure 4-16 on page 233 of the text. To use this chart we have to know two of the following three parameters: (T 0 – T)/(Ti – T), k/hro, and t/ro2. In this problem, the unknown parameter is (T 0 – T)/(Ti – T); we can find this parameter from the chart and then use the known values of Ti and T to find the temperature T0. The two known parameters are computed below. k 14.9 W hro mo C m 2 o C 1 1.42 60 W 0.175 m t k t c p ro2 60 W m 3 kg C 20 min 60 s 1 J 0.155 mo C 7900 kg 377 J 0.175 m 2 min W s ro2 o An extract from the chart is shown at the right. The value of t/r02 = 0.155 is between the vertical axis (t/r02 = 0) and the first grid line (t/r02 = 0.2). The extension of the line for k/hr0 = 1.4, shown in blue, intersects a line with t/r02 = 0.155 at a dimensionless temperature of approximately 0 = 0.92. Using this value we can find the center temperature from the known values of Ti = 400oC and T =150oC as follows. T T Ti T 0 150o C 400o C 150o C 0.92 T = 380oC 0.352