Single Sampling Variables Plan

advertisement

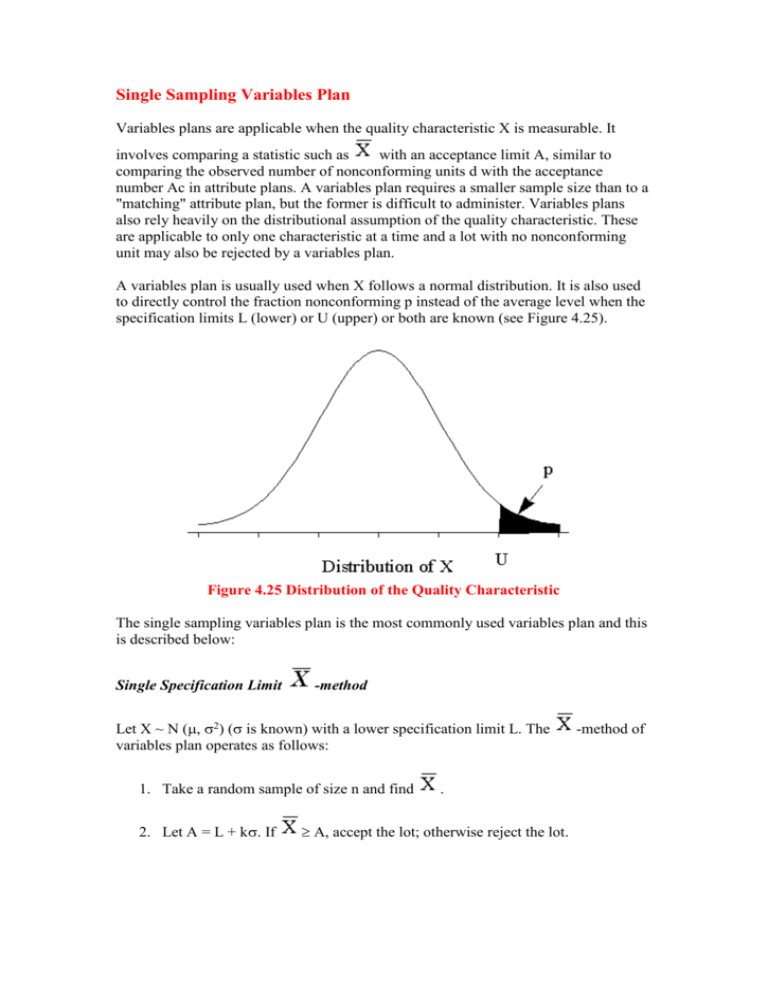

Single Sampling Variables Plan Variables plans are applicable when the quality characteristic X is measurable. It involves comparing a statistic such as with an acceptance limit A, similar to comparing the observed number of nonconforming units d with the acceptance number Ac in attribute plans. A variables plan requires a smaller sample size than to a "matching" attribute plan, but the former is difficult to administer. Variables plans also rely heavily on the distributional assumption of the quality characteristic. These are applicable to only one characteristic at a time and a lot with no nonconforming unit may also be rejected by a variables plan. A variables plan is usually used when X follows a normal distribution. It is also used to directly control the fraction nonconforming p instead of the average level when the specification limits L (lower) or U (upper) or both are known (see Figure 4.25). Figure 4.25 Distribution of the Quality Characteristic The single sampling variables plan is the most commonly used variables plan and this is described below: Single Specification Limit -method Let X ~ N (, ) ( is known) with a lower specification limit L. The variables plan operates as follows: 1. Take a random sample of size n and find 2. Let A = L + k. If . A, accept the lot; otherwise reject the lot. -method of In the case of an upper specification limit, A is set as U-k and the acceptance criterion is reversed as k (or A). A (see Figure 4.26). The parameters of the plan are n and Figure 4.26 Operation of Xbar Method k-method When is unknown, it is estimated by the sample standard deviation S (n-1 in divisor) and the plan operates as follows: 1. Draw a random sample of size n and compute Z = ( - L) / S 2. If Z k, accept the lot; otherwise, reject the lot. Equivalently, accept the lot when - kS L In the case of an upper specification limit, Z is computed as Z = (U - )/S and the acceptance criterion remains the same as Z k (or + kS U). The parameters of the plan are n and k. The operation of the k-method plan is shown in Figure 4.27. It is also noted that the and k methods are equivalent if is known. Figure 4.27 Operation of k-Method Plan For given AQL (p1), LQL (p2), producer's risk () and consumer's risk ( ), the formulae for n and k are: k= where Z is the standard normal deviate with (upper) tail area . For example, if AQL = 1%, = 5%, LQL = 4% and = 5%, the variables plan parameters are found as k= = 2.04 n= = 32.7 33 ( known) = 32.7 (1 + )= 100.7 101 ( unknown). Note that the matching single sampling attribute plan requires a sample of size 296 for the same conditions. The formula for n when is unknown is based on the normal approximation and is found to work well even though (U - ) / s follows a noncentral t distribution. M-method The operating procedure of the variables plan is also modified using the uniform minimum variance unbiased estimate of the lot fraction nonconforming p. In case of a lower specification limit, the quantity is the minimum variance unbiased estimate of p. The estimate is compared with the maximum allowable proportion of nonconforming M and the lot is accepted if M. This procedure is known as the M-method of operation of the variables plan. Note that k is defined using QL by the relation: In case of an upper specification limit, the standard normal deviate or is used and the acceptance criterion remains the same. The M-method is also equivalent to the k-method of operation of the plan. The OC curve of the single sampling variables plan is drawn using the relationships (k - Zp) = Z1-Pa (known) unknown) The following graphs (Figure 4.28) show the relationships between the auxiliary variables Zp and Z1-Pa. Figure :Relationship Between p and Pa The formulae for the AOQ and ATI functions remain the same as that of a single sampling attributes plan with Pa found from the above relationship. To draw the OC curve, usually a value for Pa is assumed and p is then obtained. Appendix A4.10 shows how to run MINITAB local macros for designing a variables plan and drawing its OC, AOQ and ATI curves. Double specification limits are beyond the scope of this course. However, they are necessary when the limits are fairly tight in relation to the inherent product variability. Otherwise, single specification limit plans may be used. In the case of a double specification limit, the proportion nonconforming may be a result of products lying beyond both the upper and lower specification limits at the same time if the variability is large. Two single specification limits can be used if the specification limits are very wide so that the occurrence of a product outside either of the limits is mutually exclusive. If Zpm = then pm is the minimum proportion nonconforming outside one of the specification limits. If pm is large, it means that the limits may be unrealistically narrow. For example, if 2pm > LQL, it means that a batch is always unacceptable and must be rejected. If 2pm > AQL, it means that a batch can never be acceptable. This suggests that the specification limits are too tight and should be loosened (widened) slightly. If < 2pm < AQL, the specification limits are still too narrow but one may proceed if a double specification limit variables plan is used. This type of plan is however beyond the scope of this course. Only if 2pm < may a single specification limit plan be used because the specification units are attainable for this product variability level(s). To select a variables scheme for given lot size and AQL, MIL-STD-414 tables were used. The switching rules of MIL-STD-414 were based on the estimation of the process average, unlike its attribute counterpart MIL-STD-105 E. These rules have been modified in the ISO standard ISO 3951:1989(E), Sampling Procedures and Charts for Inspection by Variables for Percent Nonconforming. For an example for the application of variables plans, one may refer to ISO 8197:1988(E) Milk and Milk Products - Sampling Inspection by Variables. This standard lists variable plans for normal, reduced and tightened inspections indexed by AQL and lot size. For an AQL of 1%, the following normal plans are listed in the standard: Lot Size up to 50 51 to 90 91 to 150 151 to 280 281 to 500 501 to 1200 1201 to 3200 3201 to 10,000 10,001 to 35,000 35,001 to 150,000 150,001 to 500,000 500,001 & above n 4 5 7 10 15 20 25 35 50 75 100 150 k 1.45 1.53 1.62 1.72 1.79 1.82 1.85 1.89 1.93 1.98 2.00 2.03