Chapter 2: construction, watertight and weathertight

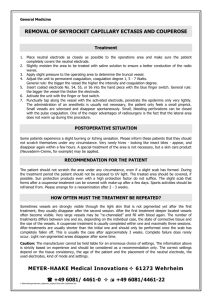

advertisement