Irrigation of food crops with treated wastewater

advertisement

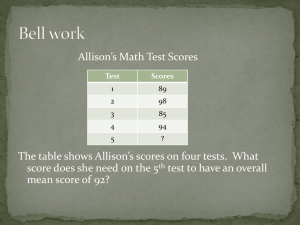

Case study 3: Irrigation of food crops with treated wastewater Problem Formulation (Background, goal, and breadth) The wastewater treatment plant Harnaschpolder near Delft is one of the largest in Europe. It collects and treats the wastewater of more than 1 million people, treats with conventional biological treatment and discharges 10.000 m³ secondary effluent per hour (dry weather flow). The wastewater effluent could be an alternative source of fresh water for the greenhouse sector – after further treatment. The greenhouse sector does not want to compromise the safety of greenhouse produce for consumers and also for the greenhouse workers. The owners of the wastewater treatment are conducting a research project to look at treatment options. Currently they suggest 2 different treatment lines, 1: use sand filtration and multimedia filtration (for N/P removal) followed by ultrafiltration and reverse osmosis, but this is expensive (different lines shown in Figure 1). Objective: Assess the risk/probability that lettuce consumers and workers in the greenhouses will get an infection after consuming the lettuce and after exposure to wastewater during irrigation. Propose the control measures to reduce the risk to consumers and workers and evaluate the effectiveness of these measures. Stakeholders: 1. Wastewater treatment plant operators and administrators 2. Farmers/ workers of green houses 3. Consumers 4. Technology vendors 5. Health authorities 6. National/ international regulatory authorities 7. Residents of the region Figure 1: Treatment lines. LINE 1: Reference treatment (conventional + membranes): no chemical disinfection WWTP effluent VIRUS 2-4 Log VIRUS 1-2 Log Microbiological barriers SAND FILTRATION MULTIMEDIA FILTER 100um-10um 100um-1um NO3- PO4- & Susp. solids UF RO 100-10nm <1nm Susp. Solids Salts & Dissolved Compounds LINE 2: Innovative line (membranes): no chemical disinfection VIRUS 0.2-1 Log Microb. barriers BiopROtector NO3- & Nutrients 3FM / DiscFilter Suspended solids VIRUS 2-4 Log AiRO <1nm Salts & Dissolved Compounds Only 1 effective barrier against virus at the end TREATMENT Sand Filtration Microfiltration (MF) Ultrafiltration (UF) Nanofiltration (NF) Reversal Osmosis (RO) Reversal Osmosis (RO) UV irradation LOG REMOVAL VIRUSES 0.1-2 0.2-2 1-4 3-7 1.4-3.6 3-7 2-3 REFERENCE Shirasaki et al. Water Research (2010) B. Zhu et al. Water Research (2005) Madaeini S.S. Water Research (1999) O'Grady. Dev. Biol. Stand. (1996) EPA/NSF (2006) Madaeini S.S. Water Research (1999) Hijnen et al. Water Research (2006) Available data: No data is available concerning the treatment efficiencies and the microbial concentrations of the secondary sewage, and therefore should be obtained from literature or by estimation. Chemical parameters in the secondary treated water are available but this risk assessment focuses on the microbial contamination of the water to assess the public health risk. Necessary data: Risk assessment paradigm: 1. Hazard Identification To perform a microbial risk assessment several pathogens could be used. Because enteric viruses are often found in sewage, even in high concentrations, and are difficult to remove with conventional treatment processes viruses could be considered as a conservative choice. Rotaviruses are causing gastrointestinal disease and adenoviruses are causing both gastroenteritis and acute respiratory illnesses. 2. Hazard characterization a. Dose response analysis For both rotavirus and adenovirus a dose response is available b. Health effects/ health outcomes/ type of disease 3. Exposure Assessment a. Exposure routes i. Direct consumption of lettuce by consumers ii. Inhalation of water by workers iii. Accidental ingestion of water by worker iv. Direct contact between worker and water: ingestion of water by uptake the aerosols and surface to hand to mouth contact b. Exposure frequency and duration c. Exposure volume (ml) d. Breath volume and frequency e. Number of people exposed / annual infection risk Exposure pathways: Table 1: Consumer Exposure Pathway 1 Parameter name [rotavirus] in sewage effluent Value 0.873 Unit pfu/ml Assumption The data was derived from different treatment processes, and a average was calculated Reference Oragui et al. (1989) Smith and Gerba (1982) Bates et al. (1984) Recovery of the method 0.5 % Removal efficiency of the treatment Total concentration of viruses in 7 days Volume of water in leafs after irrigation Number of irrigations per day 4 or 6 ulog1 0.0004738 85 10.8 pfu/ml 2 n Reduction/die-off 0.69 ulog/day Time between harvest and consumption 2 days Washing procedure at home Diary lettuce consumption 2 ulog2 22.5 g/person/ day ml Log normal distribution Assumption = 50 % recovery with the applied detection method 4 or 6 log reduction obtained with the applied treatment Accumulation of the viruses on the lettuce after 7 days Described in literature Normal distribution Assumption = normally there will be 2 irrigations per day, under dry conditions it will be 3 times and under more humid conditions it will be 1 time Custom distribution Described in literature Normal distribution Assumption = 2 days after harvesting the lettuce is comsumed Triangular distribution Described in literature Normal distribution Described in literature Normal distribution Rao et al. (1988) ?? Hamilton et al. 2006 Hamilton et al. 2006 P.Gale et al 2005 GEMS/Food Regional Diets, 1998 Table 2: Rotavirus single and annual risks for consumers through ingesting lettuce Risk Annual Risk mean (SE) median (SE) 90% (SE) 99.99% (SE) mean (AR) median (AR) 90% (AR) 99.99% (AR) 4.70E-05 3.96E-09 2.62E-06 4.05E-02 2.23E-03 2.77E-07 1.84E-04 9.45E-01 6.40E-04 3.53E-07 1.90E-04 2.40E-01 1.90E-02 2.50E-05 1.40E-02 1 Treatment line 1 Treatment line 2 SE: Single event AR: Annual Risk Median and 90 Percentile Rotavirus Risk and Annual risk for Consumers- Lettuce Consumption Treatment line 1 1.00E+00 1.00E-01 1.00E-02 1.00E-03 1.00E-04 1.00E-05 1.00E-06 1.00E-07 1.00E-08 1.00E-09 Treatment line 2 median (SE) 90% (SE) median (AR) 90% (AR) SE: Single event risk AR: Annual Risk Table 3: Worker Inhalation Exposure Pathway 2 Parameter Name Concentration of Adenovirus in effluent Recovery efficiency Value 20 Unit Pfu/mL Assumptions Log normal distribution 0.5 % Treatment removal efficiency T1 Treatment removal efficiency T2 6 Log10 50% recovery efficiency is assumed Triangular distribution Triangular distribution 4 Log 10 Triangular distribution Reference Fong et al. (2009) Humidity 0.8 % Breathing rate 23 L/min Time 120 min Volume of water inhaled 2.208 L Percentage of particles generated by the spray device in respirable range 75 % Percentage of particles deposited in lungs 4.1 % Normal distribution Maximum 1.0 and Minimum is 0.8 High humidity reflective of hot house conditions Adult male light physical activity Log normal distribution and breathing rate for 20 year old during heavy exercise specified as maximum Assumed that viruses would remain in the air for a period of 2 hours following spray irrigation and/or worker in vicinity during and post spray for a period of 2 hours No die-off of viruses Triangular distribution Computation based on 120 min 80% humidity and breathing rate No distribution specified High pressure hose device used for irrigation Percentage based on a range of experiments showing 69-96% for trigger nozzles and humidifiers No distribution specified point estimate used Only a proportion of aerosols of size 5 microns are deposited in the alveoli No distribution specified point estimated used Haas et al 1999 Finlay 1994 Anderson et al 2007 Haas et al 1999 Anderson et al 2007 Anderson et al 2007 O’Toole et al 2009 ICRP Dosimetric model Table 4: Single and annual risks for workers exposed to adenovirus through inhalation Treatment line 1 Treatment line 2 Risk Annual Risk mean (SE) median (SE) 90% (SE) 99.99% (SE) mean (AR) median (AR) 90% (AR) 99.99% (AR) 3.95E-03 1.81E-06 1.78E-03 7.85E-01 9.30E-02 3.97E-04 3.24E-01 7.85E-01 7.45E-03 4.91E-05 8.78E-03 8.62E-01 1.75E-01 1.08E-02 8.56E-01 1.00E+00 Median and 90 Percentile Adenovirus Risk and Annual risk for Workers- Inhalation Treatment line 1 Treatment line 2 1.00E+00 1.00E-01 1.00E-02 median (SE) 90% (SE) 1.00E-03 median (AR) 90% (AR) 1.00E-04 1.00E-05 1.00E-06 Table 5: Worker Ingestion Exposure Pathway 3 Parameter Concentration of rotavirus Value 0.873 Unit ufp/ml Assumption Taking the average of the highest Reference Oragui et al. (1989) in effluent sewage Recovery method Treatment removal efficiency 0.5 % 6 ulog1 concentrations’ results in considering the worst case (conservative action). They derived from different treatment methods. Using log normal distribution. Assuming 50 % recovery with the applied detection method. Using triangular distribution. Using multiple barriers before using that water in the irrigation of lettuce I n greenhouses. 6 log reduction obtained with the applied treatment Using triangular distribution. & Rao et al. (1988) Volume aerosols ingestion per event 1 ml Numbers of events per day 2 No. Volume on hands 0.01 ml Volume transfer to mouth 0.33 % Number of hand to mouth 120 No. Based on estimates by NSW firefighters about volume exposure per event. This is mean value Assumed high pressure irrigation system Using log normal distribution. Assuming 2 irrigations per day as a normal situation, 3 times under dry conditions and 1 time under more humid conditions. Using custom distribution. Based on volume transfer obtained for surface to hand transfer Using log normal distribution. Based on transfer of 33.9% observed for hand to mouth transfer of PRD-1 bacteriophage Using normal distribution. 15 times of the workers hands’ touching their mouths multiplied by 8 working hours. Using normal distribution. Shirasaki et al. Water Research (2010), B.Zhu et al. W. Research (2005), Madaeini S.S. Water Research (1999), O'Grady. Dev. Biol. Stand. (1996), EPA/NSF (2006), Madaeini S.S. Water Research (1999) Hijnen et al. W, Research (2006) Dan Deere 2004 - O’Toole et al 2009 Rusin et al 2002 Nicas, M, & Jones, RM, (2009) Table 6: Single and annual risks for workers exposed to rotavirus through ingestion and surface-mouth contact Treatment line 1 Treatment line 2 Risk Annual Risk mean (SE) median (SE) 90% (SE) 99.99% (SE) mean (AR) median (AR) 90% (AR) 99.99% (AR) 5.40E-04 1.86E-07 2.27E-04 1.90E-01 3.74E-02 4.09E-05 4.86E-02 1 1.08E-03 5.35E-06 9.54E-04 2.45E-01 7.34E-02 1.17E-03 2.13E-01 1.00E+00 Median and 90 Percentile Rotavirus Risk and Annual risk for Workers- Ingestion & Hand- Mouth Contact Treatment line 1 Treatment line 2 1.00E+00 1.00E-01 1.00E-02 median (SE) 1.00E-03 90% (SE) 1.00E-04 median (AR) 90% (AR) 1.00E-05 1.00E-06 1.00E-07 SE: Single event risk AR: Annual Risk Table 7: Consumer Exposure Pathway 4 – Accidental exposure Parameter name [rotavirus] in sewage effluent Value 0.873 Unit pfu/ml Recovery of the method 0.5 % Removal efficiency of the treatment 4 or 6 ulog1 Frequency of event Volume of water consumed Pfu = plaque forming units Ulog1 = log removal N = number 1 100 days mL Assumption The data was derived from different treatment processes, and a average was calculated Log normal distribution Assumption = 50 % recovery with the applied detection method Triangular distribution 4 or 6 log reduction obtained with the applied treatment Triangular distribution Uncommon event Normal distribution This is equivalent to a cup of water Reference Oragui et al. (1989) Smith and Gerba (1982) Bates et al. (1984) Rao et al. (1988) AGWR, 2006 Table 8: Annual risk for workers exposed to rotavirus through accidental ingestion Treatment line 1 Treatment line 2 Annual Risk mean median 90% 99.99% 9.40E-03 1.09E-05 1.20E-02 4.86E-01 1.65E-02 2.64E-02 4.77E-02 4.90E-01 Median and 90 Percentile Rotavirus of Annual risk for WorkersAccidental Ingestion Treatment line 1 Treatment line 2 1.00E+00 1.00E-01 1.00E-02 median 90% 1.00E-03 1.00E-04 1.00E-05 SE: Single event risk AR: Annual Risk Conclusions - Lower viral health risk for Treatment 1 for both workers and consumers - Treatment 1 leads to production of lettuce which meets drinking water standards (1/10000 infection per annum) - Treatment 2 is a new technology and few data are available about its efficacy Recommendations – To assess the risk of using treated effluent from this location pathogens should be measured in the secondary effluent over time (for instance during one year to cover also possible seasonal distribution). Because it is probably difficult to detect these pathogens in small volumes of water the concentrations in this secondary effluent should subsequently be used in a QMRA (using the different log removals from the different treatment processes). To estimate the viability of pathogens culture methods should be used. – Indicator organisms, like bacteriophages, could be used to determine the removal in the different treatments. – To reduce the risk of formation of aerosols by drip irrigation. – To reduce the risk of surface contamination of crops by using drip irrigation (drip irrigation gives an additional 2log removal). – Crop selection (e.g. non edible crops). – To investigate a third treatment train which will be more cost effective (lower operation cost) and will introduce a specific disinfection process to produce water suitable for edible crop irrigation. Datagaps - Methods for isolation and detection of enteric viruses and other pathogens in water and environmental surfaces, including hands - Methods to determine viability of pathogens present in water and environmental surfaces, including hands - Assay methods to determine the percentage of aerosol mass transmitted via inhalation versus ingestion during water using activities - Data quantifying the transmission, persistence and inactivation of pathogens in a variety of exposure scenarios - Data quantifying the relationship between the transmission, persistence and inactivation characteristics of pathogens and their surrogates used in experimental and field studies (i.e. where no assay methods are available for pathogens or there are safety and/or logistical reasons for not using pathogens). - Interaction of foodborne pathogens with plant tissue Risk communication: - It is important that the stakeholders are consulted from the outset of the project, and that a risk communication strategy is devised in advance of the implementation of any new scheme. For example provision of information about water reuse and detailing benefits of the scheme should be provided to green house farmers. Study group members: Fernando Valero Cervera: ATLL, Spain Joanne E. O’Toole: Monash University, Australia Mahjid M. Alkhalaf: Saudi Food and Drug Authority, Saudi Arabia Michel Montemayor van Rooy: ATLL, Spain Sahar S. Dalahmeh: SLU, Sweden Willemijn J. Lodder: RIVM, the Netherlands Supervisor: Dr. Joan Rose