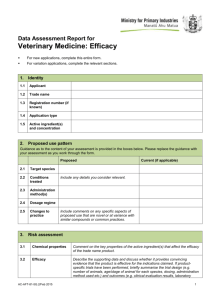

1.4 Efficacy testing of the product - CIRCABC

advertisement