pick & place - ITM Consulting

advertisement

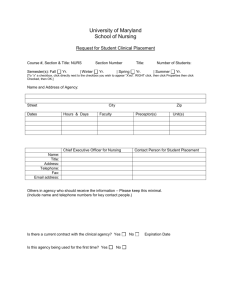

CIRCUITS ASSEMBLY MAGAZINE On The Forefront: October, 1996 Automatic Component Placement Systems by Phil Zarrow At the heart of the SMT assembly process, lives the component placement system. Also commonly called the “pick and place” machine, it is simply a flexible machine that takes components from their “feeders” and places them accurately onto the printed circuit board. Of course that’s where the simplicity ends. The component placement system is usually, by far, the most complex machine center in the assembly process. A computer controlled electromechanical “beast”, the pick and place machine is also typically the slowest machine in the process and is thus the gating factor in through-put speed. In the early days of surface mount technology, one of the virtues extolled upon SMT was that it was highly automatable. With through-hole insertion, it was expensive to automate the process. To fully automate the populating of a typical through-hole assembly would require a sequencer and inserter for axial leaded components (later these two machine center were combined to form one sequencer/inserter), a radial sequencer/inserter for radial components, and a sequencer/inserter for DIPs. These (fully automatic) machines typically cost between $70,000 to $300,000. Consequently, it took a fairly amount of volume to justify this cost and with labor rates much lower “off-shore” a good deal of hand assembly was done in Asia and Mexico. By comparison a single pick and place machine could place the surface mount equivalent of this variety of components (axial, radial and ICs) at the cost of a single auto-insertion machine and requiring a fraction of the factory real estate. Hence, automated assembly was in the reach of a far wider range of assemblers. Even a “Ma and Pa” job shop could afford a basic component placement system. An interesting historical note is that SMT was thus touted by some as a means of bringing electronic manufacturing back to North America and Europe (and away form Asia) since assembly could now be done more economically. Why it never occurred to them that the technology and its high degree of automation wouldn’t be rapidly and very successfully implemented there as well is a mystery. In any event, the continuation of the electronic manufacturing services industry (EMSI) to manifest itself as the largest growing segment of the electronics industry is largely due to the advent of SMT. Of course, while it is true that SMT is highly automatable, in order to assemble boards in a timely, accurate and repeatable fashion, it is highly recommended that one does, indeed, automate. This is particularly true of the component placement operation (as those of us who have hand-assembled SMT boards will attest). Regardless of the sophistication of the component placement system, almost all of the machines on the market have “the basics” in common. The substrate is either placed (by the operator) or automatically transported to staging area. Components are “picked” from assigned pickup bin locations by vacuum and usually realigned using either mechanical or optical means. The component is then placed in its programmed location accurately. Most systems employ vision and a host other accouterments are available to enhance accuracy of placement, through-put speed and system flexibility. Pick and place machines are characterized in terms of three primary features: accuracy, speed and flexibility. Accuracy deals with the precision of placement capability of the machine - its ability to position a component with respect its target position on the PCB. This can be examined by measuring the translational error (misalignment of the component centroid) and the rotational error (angular displacement of component axes). Repeatability, the ability of the placement system to repeatedly return to the target point, is another key component of accuracy. Resolution, which is a measure of the finest increment the placement machine can move, also factors in as it defines the ultimate precision of the machine. However, it should never be used as the sole specification for machine accuracy, as it commonly is. It is possible for one machine with high resolution to have poorer total accuracy that a different machine with lower resolution. The entire accuracy picture must be considered. While the speed of the component placement system will usually be the limiting factor in the overall line capacity, it is difficult to quantify a machines actual speed and makes intermachine comparison perplexing. There are a number of inter-related parameters that directly influence speed including: PCB board design / layout number of feeders feeder locations production lot size setup complexity PCB board loading program efficiency The most commonly used data sheet specification is the equipment placement rate. This is defined as the speed at which an average placement cycle is completed. A placement cycle is comprised of a complete round trip from pickup site to placement site and return. Of course, using a component feeder in very close proximity to where it will be placed will yield the more impressive number. Credulous suppliers will usually state the trip distance that was used to derive their stated placement rate. While cycle rate is similar to placement rate, it embodies operation in a dry cycle mode - without components. Therefore, such a figure is virtually useless in terms of predicting production throughput. The most important parameter, from a user’s point of view, is the production throughput of a component placement system. This is defined as the number of components placed per hour over an entire production shift: Total # of components placed Length of shift For example, if 50,000 components were placed during the course of an 8 hour shift, the production throughput would be 6,250 components/hour. Production throughput is, hence, derived by applying some of the following derating factors: Board load / unload time Production mix Machine configuration Component mix Available hours (in a shift) Unscheduled downtime For various sundry reasons, a user should never take the published throughput specifications verbatim. The following derating factors serve as good rules of thumb: “PHIL FACTOR” For Levels I through III: 55% Equipment Manufacturer’s Specified Placement Rate x .55 = Typical User Production Throughput For Level IV: 90% Equipment Manufacturer’s Specified Placement Rate x .90 = Typical User Production Throughput The final key area of consideration is flexibility. How adaptive is the component system to a range of applications. Some systems are highly flexible in that they can handle a wide range of PCB substrate sizes as well as a wide range (and number) of component packages and respective feeders while others, such as “chip-shooters” may be restricted to handling passives albeit at a very high speed. Regardless of the type of system, feeder capacity is commonly expressed in terms of the number of 8mm tape feeders that can be mounted since almost all systems on the market can handle passives fed in this format. Ease of setup is another contributing factor to the flexibility of a system. Machine setup is defined as the steps necessary to change over from building one board to another. These steps typically involve machine re-programming and/or file downloading, feeder changeover as well as board handling width adjustment or tooling plate changeover. It was determined some years ago that by examining the co-relation of flexibility and speed, a categorization of component placement systems can be conjured. Though by far not a perfect system 1, it is useful for classification of the automatic component placement systems on the market. Level 1 is comprised of bench-top systems. Usually very limited in the size of substrates they can handle as well as the number of feeders that can be accommodated they are, nevertheless, good for prototyping, pre-production and very short runs. Though at one time they were referred to in the field as “random placement machines” and “pick and throw”, today’s offerings are extremely accurate. Level II are high flexibility machines. Some are in-line while others are quasiinline in that they can be adapted for flow-through production. They typically handle a very wide range of component types and feed formats and many are extremely accurate. These machines are also called flexible placement systems. Level III are fairly flexible and are also considered flexible placement systems because, like their slower counterparts in Level II, they handle a wide range of component packages from passives to QFPs, SOPs and BGAs. However, they achieve a higher throughput rate than Level II and are almost always in-line systems. Between Levels II and III fall the Flex-cells. These systems were discussed in the August “On The Forefront”. Level IV are the proverbial “chip shooters”. Limited to achieving high speed when fed only with 8mm and 12mm tape feeders, they are extremely fast. Always in-line, most utilize a turret-head approach. Level V was originally classified as mass-placement machines. These highly inflexible machines had dedicated vacuum pickups for each component. They 1 No one has yet to come up with a better system. were limited to passives only and involved a great deal of set-up time. It is in this area that there is equipment evolvement taking place. Systems that use multiple heads to place six components each, arranged in-line have been introduced. Pioneered by the Philips FCM series, though limited to passives (and hence having low flexibility), these systems achieve very high throughput - capable of exceeding those of their predecessors, the mass-placement machine, with greater accuracy and lower set-up time. With costs not much greater than Level IV systems, the configuration allows for a very small factory footprint. There is a great deal more to component placement than can be discussed in the confines of this column. With over 60 different manufacturers of pick and place systems worldwide (most offering several machines within different levels), there is a great deal of competition and equipment evolution can be expected to continue. Component Placement System Categorization. Category Attributes Typical Throughput < 1000 pph Level I Low Speed / Low Flexibility Level II Medium Flexibility Flex-cell Low to Medium Speed / High Flexibility Level III Medium to High Medium Flexibility Level IV High Speed / Low Flexibility Level V Very High Flexibility Speed Speed / High Speed / / Low Suppliers Zevatech / Juki OK Industries Celmacs 500 - 5000 pph Mydata Quad Zevatech Siemens Philips Multitroniks Contact Systems Celmacs Amistar Tescon Sony Citizen 100 - 4000 pph Universal Zevatech Philips 3000 - 10,000 Mydata pph Quad Zevatech Siemens Philips Panasonic Fuji TDK Universal Inst. KME Tescon 14,500 - 38,000 Fuji pph Panasonic TDK Sanyo Universal Inst. KME 40,000 - 90,000 Philips pph Fuji